metal fabrication shop drawings connections Our fabrication shop drawings services cover the entire pipe layouts. They feature exact dimensions for pipe lengths, connections, and materials for efficient water flow and compliance . This will show your sheet metal dimensions (thickness, radius, and K factor for me). Then you can modify the thickness by double clicking it, and then link it to your assembly level custom property. Works perfect.

0 · structural steel shop drawings

1 · structural steel bridge shop drawing

2 · steel shop drawings

3 · steel shop drawing instructions

4 · steel bridge shop drawings pdf

5 · steel bridge shop detail drawing

6 · bridge shop detail drawing

How to Add an Air Duct to a Room step by step instructions. Frame-in and mount the new vent boot, install the rigid duct board start collar and connect the flexible duct branch line to the duct board trunk. This project is continued from How to Add a Room Air Duct – Part 1.

Since fabrication drawings have information on them based on each Fabricator's equipment and fabrication processes, they may vary from the drawings shown. At this time, for the purpose of . Steel shop drawings aid in reducing errors and inconsistencies during fabrication and erection by detailing every aspect of the steel components, including their placement, orientation, and connection specifics.The intent of the Shop Detail Drawings is to provide instruction to the fabrication shop regarding how the components are to be fabricated. Shop drawings and erection drawings are types of .Our fabrication shop drawings services cover the entire pipe layouts. They feature exact dimensions for pipe lengths, connections, and materials for efficient water flow and compliance .

Our detailed shop drawings encompass a myriad of elements: Precise Measurements: Our drawings go beyond mere aesthetics. They provide precise measurements and dimensions . Purpose: Structural steel shop drawings act as a roadmap, guiding contractors, erectors, and fabricators on the appropriate dimensions, connections, and specifications of the .Signage Fabrication Shop Drawings are essential technical documents that guide the manufacturing, installation & placement of signs on your structure or walls. . we develop connection methods between different components, make load considerations, provide clear fabrication instructions for clear construction & include assembly diagrams . In general, for steel, connections are to be made with shop welds and field bolting. 1.05 SUBMITTALS A. General: Submit each item in this Article according to the General and Special Conditions . C. Shop drawings showing sizes and detailing fabrication and erection of each metal fabrication indicated. Include plans, elevations, sections .

What type of services do companies rely on when picking fabrication shop drawing services? Before any construction begins, numerous drawing sets (each bringing their significance to the project) are prepared. These drawings are then used from preconstruction to post-construction to inform the construction process and ensure accuracy. To this end, architects prepare many . 3 Sheet Metal Fabrication Drawings FAQ. 3.0.1 Why is it important to list part numbers in addition to part names in sheet metal fabrication drawings? 3.0.2 How can providing the exact hardware name help expedite precision sheet metal fabrication? 3.0.3 Why should revision control details be documented in sheet metal fabrication projects? This post covers a few valuable tips on how to improve cabinet shop drawings for manufacturing efficiency. Cabinet drawings detail the cabinet design process to the manufacturing stage. The cabinet manufacturing process involves collaboration between the 3D concept design team, planning, and manufacturing departments. These departments collaborate to turn .Today shop drawings are a necessary component in construction. A2Z SHOP DRAWINGS CORP. is a proud american steel detailing company based in New York City (NYC) that provides services for a variety of professionals. We work with fabricators, manufacturers, contractors, subcontractors, engineers and architects since 2005.

Ideally we review checked shop drawings simultaneous to the EOR review. The detailer incorporates our comments and the EOR comments at the same time, and we seal the "for fabrication" drawings. IMHO the intent of requiring a connection engineer is based primarily on the need for the additional review of shop drawings. Fabrication drawings or shop drawings, for instance, are integral parts of a complete set of design drawings but are more specific to parts and usually prepared by suppliers or vendors themselves. Shop drawings apply to metal or steel fabrication, PVC fabrication, composite, and any type of construction.

Fabrication drawings (I'm thinking these are like steel shop drawings - right?) are prepared by shops who are taking your design drawings and providing plans for use in a shop to fabricate the "pieces" of your structure. . On projects where I am the SER, I review all shop drawings and verify that connections are adequate. When I . One of ESC’s Engineering capabilities in metal fabrication is to produce all types of CAD drawings in 2D and 3D models, including visualizations using Finite Element Analysis (FEA) system. It may not be a significant edge in the first place, since almost all fabrication companies have the ability to do the same. But here’s the difference – in ESC, our engineering .Enhance accuracy with detailed metal shop drawings and fabrication drawings explicitly designed for manufacturers and contractors. Search; Blog; US; Home; Engineering. Portfolio Testimonials Case Studies. 3D Rendering & VR . We provide metal shop drawing services for the following industries. High Rise. Office Buildings; Multi-Story . One of ESC’s Engineering capabilities in metal fabrication is to produce all types of CAD drawings in 2D and 3D models, including visualizations using Finite Element Analysis (FEA) system. It may not be a significant edge in the first place, since almost all fabrication companies have the ability to do the same. But here’s the difference – in ESC, our engineering .

Fabrication drawings often indicate where bolt holes should be drilled, how welding should be performed, and where stiffeners should be placed. These instructions are essential for fabricating components that will fit together correctly on-site. Shop Drawings. Shop drawings are even more detailed than fabrication drawings. Short of providing CNC files for the shop which can be easily coded by a fabricators CNC programmer, 2D drawings can be argued to be more than adequate to provide accurate shop drawings. Detailers can hand sketch in 3D which allows them to think of the best approach in lieu of sifting through a long list of canned connection options. Fabrication Guide: Provide precise . Connection Methods: Types of fasteners, . Shop drawings for metal roof components and assemblies are a crucial aspect of the construction process. They .

One of ESC’s Engineering capabilities in metal fabrication is to produce all types of CAD drawings in 2D and 3D models, including visualizations using Finite Element Analysis (FEA) system. It may not be a significant edge .The engineers doing the design drawings aren't sourcing all the parts, they aren't specificying means and methods. So things change between design and fabrication. Usually just more detail. It's up to the fab shop to meet the criteria specified by the design engineer and usually the design engineer reviews and approves the shop drawings.In the world of metal fabrication, precision, efficiency, and adaptability are the cornerstones of success.Metal fabrication shops face unique challenges when meeting the needs of their customers, who often demand high-quality OEM products, tight deadlines, and custom solutions.To overcome these demands, it’s crucial for metal fabrication shops to not only .

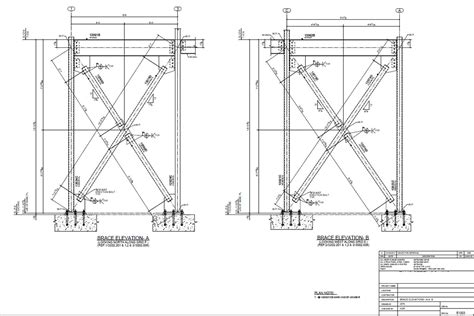

Let's finish it off with fabrication/Shop Drawings. . By trade I'm a Timber Frame Designer using Horizon add-on to produce Manufacturing drawings for Prefabricated Panels, Metal Joists and Floor Cassettes . If the Structural Connections could be added to the assembly most of the manually modeled in place families would not be required . Chapter #7 – Sheet Metal Shop Drawings Shop drawings should be created by someone in the company familiar with detailing. Detailing is the process of taking the engineered set of drawings and converting them into shop drawings that the field will use to install the sheet metal. Sheet Metal Detailer The sheet metal detailer’s job [.]Usually shop drawings are reviewed for general conformance to the contract plans, not checking every single line on the sheet, unless, that’s what the contractual obligations are. . then it becomes a fabrication issue if the screw it up tbh . Final substantiating connection information, if any, shall also be submitted with the approval . Here’s a breakdown of the different types of fabrication shop drawings: Steel Fabrication Drawings. These drawings are used in projects involving steel structures, such as beams, columns, and frames. They show the exact size and shape of steel components, along with details on welding, bolting, and other connections.

ceiling junction box cover kitchen

Shop drawings for connections is a concise and detailed illustration of equipment or structural component intended to be made by a fabrication shop. [email protected] (424) 414-0997; . The importance and prominence of shop drawings for fabricators, engineers, designers, and other industry specialists cannot be exaggerated. Shop drawings for .Steel Detailing India is an experienced and expert steel detailing services firm which provides cutting edge structural steel detailing solutions for residential, commercial,airport terminals, roads and highways, stadiums, museums and industrial sectors. We act as an extension to the in-house steel detailer team for our worldwide clients and support them in the virtual steel detailing .Structure of building typically designed by a structural Engineer. shows connections on the drawings. The shop drawings are sent to engineer for approval. Fabrication begins if the shop drawings are approved. 1 / 26. 1 / 26. Flashcards; Learn; Test; Match; Q-Chat; . • Metal decking provides a safe environment for workers to walk around on .

If detailers give erectors drawings that spell out the sequence and connections, and they’re on sturdy paper that can withstand the elements, a raising-gang foreman’s day will go a lot smoother, and he’ll accomplish a lot more in less time. “We’re in the digital age, and we do use tablets for shop drawings,” Deem said.Which of the following is primarily responsible for preparing structural steel shop drawings, which show details of connections, exact spacing of bolt holes, anchor bolt sizes and locations, and so on, and for to the site steel components that are ready to be assembled without further processing? a. Steel fabricator b.

structural steel shop drawings

structural steel bridge shop drawing

steel shop drawings

All of the electrical wiring, luminaires, equipment, and appurtenances related to electrical installations within a mobile home park, including the mobile home service equipment. 550.4 General Requirements.

metal fabrication shop drawings connections|steel bridge shop detail drawing