adaptive control system in cnc machines pdf Control systems of computerized numerically controlled (CNC) machines from NC’s to humanoid robots are striving to have capabilities of adaptive control modules to excel themselves to . Sheet Metal Bending Defects “Springback” is one of the key bending defects, also associated with stamping and other forming processes. Metal sheet tends to regain their original position after deformation ( by a certain %). It means a portion of the deformation goes back into the initial position. It affects the dimensional accuracy of .

0 · adaptive controlling cnc machine

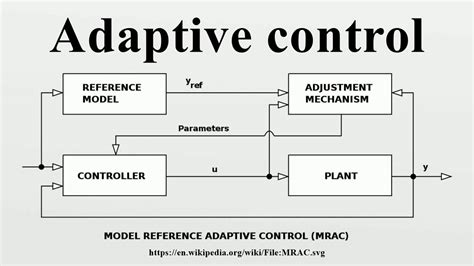

1 · adaptive control systems for machining

2 · adaptive control systems

3 · adaptive control process

4 · adaptive control for metal cutting

5 · adaptive control for machining PDF

6 · adaptive control cnc process

7 · adaptive control PDF

A junction box contains two 3-in. raceways on the left side, one 3-in. raceway on the right side, and one 3-in. raceway on the bottom. The conductors from the lower 3-in. raceway on the left wall are pulled through the 3-in. raceway on the right wall.Understanding the steps in the sheet metal stamping process demonstrates how high-quality components are produced, guiding businesses toward informed decisions and efficient operations. This comprehensive guide serves as your roadmap to navigating and leveraging .

AC systems for machine tools can be classified into three categories [3, 4]: (1) adaptive control with optimization (ACO), (2) adaptive control with constraints (ACe), and (3) geometric .Adaptive control (AC) systems are aimed at providing an additional level of control to .Control systems of computerized numerically controlled (CNC) machines from NC’s to humanoid robots are striving to have capabilities of adaptive control modules to excel themselves to .

The paper discussed basic classes of adaptive control: adaptive control with optimization (ACO), adaptive control with constraints (ACC), and geometric adaptive control (GAC), as well as. as to maximize the metal removal . This article presents the concept and innovative use of adaptive smart machining through the adaptive control by constraints system, based on feed rate adjustment to modify .

Abstract: In this work, an adaptive control constraint system has been developed for computer numerical control (CNC) turning based on the feedback control and adaptive control/self .a new structure of an adaptive CNC controller by taking the advantages of well-known IEC61499 and STEP-NC standards. For realising adaptive CNC controller capability, integration of the .

This paper implements an adoptive Neuro-fuzzy interface system (ANFIS) to actualize an efficient model for prediction of cutting forces during conventional milling with minimum average test error. This paper presents an efficient optimization method of combining off-line optimization with on-line adaptive control for CNC (Computerized Numerical Control) .Adaptive Con~rol. The control system is based on a PDP-11 mlnl comnuter which performs all the normal functions of numerical control and in addition carries the Ada11tive Control .

adaptive controlling cnc machine

AC systems for machine tools can be classified into three categories [3, 4]: (1) adaptive control with optimization (ACO), (2) adaptive control with constraints (ACe), and (3) geometric adaptive control (GAC). ACO refers to systems in which a given performance index (usually an economic func tion) is extremized subject to process and system .Control systems of computerized numerically controlled (CNC) machines from NC’s to humanoid robots are striving to have capabilities of adaptive control modules to excel themselves to perform better in challenging conditions of non conformities. The paper discussed basic classes of adaptive control: adaptive control with optimization (ACO), adaptive control with constraints (ACC), and geometric adaptive control (GAC), as well as. as to maximize the metal removal rate (MRR). AC systems, however, are not widely used in practice due to the following factors: A lack of detailed understanding of the machining process.

This article presents the concept and innovative use of adaptive smart machining through the adaptive control by constraints system, based on feed rate adjustment to modify the orthogonal.Abstract: In this work, an adaptive control constraint system has been developed for computer numerical control (CNC) turning based on the feedback control and adaptive control/self-tuning control.

a new structure of an adaptive CNC controller by taking the advantages of well-known IEC61499 and STEP-NC standards. For realising adaptive CNC controller capability, integration of the native process planning decision-making function into CNC controller will be established. The activities such as cutting tool

This paper implements an adoptive Neuro-fuzzy interface system (ANFIS) to actualize an efficient model for prediction of cutting forces during conventional milling with minimum average test error. This paper presents an efficient optimization method of combining off-line optimization with on-line adaptive control for CNC (Computerized Numerical Control) machining parameter, and develops the corresponding system, aims to multi-Adaptive Con~rol. The control system is based on a PDP-11 mlnl comnuter which performs all the normal functions of numerical control and in addition carries the Ada11tive Control measurements, orocessino and actuation. The computer operations are synchronized to a 20 mSec real-time clock. On receipt of each

AC systems for machine tools can be classified into three categories [3, 4]: (1) adaptive control with optimization (ACO), (2) adaptive control with constraints (ACe), and (3) geometric adaptive control (GAC). ACO refers to systems in which a given performance index (usually an economic func tion) is extremized subject to process and system .Control systems of computerized numerically controlled (CNC) machines from NC’s to humanoid robots are striving to have capabilities of adaptive control modules to excel themselves to perform better in challenging conditions of non conformities.

The paper discussed basic classes of adaptive control: adaptive control with optimization (ACO), adaptive control with constraints (ACC), and geometric adaptive control (GAC), as well as. as to maximize the metal removal rate (MRR). AC systems, however, are not widely used in practice due to the following factors: A lack of detailed understanding of the machining process.

adaptive control systems for machining

This article presents the concept and innovative use of adaptive smart machining through the adaptive control by constraints system, based on feed rate adjustment to modify the orthogonal.Abstract: In this work, an adaptive control constraint system has been developed for computer numerical control (CNC) turning based on the feedback control and adaptive control/self-tuning control.a new structure of an adaptive CNC controller by taking the advantages of well-known IEC61499 and STEP-NC standards. For realising adaptive CNC controller capability, integration of the native process planning decision-making function into CNC controller will be established. The activities such as cutting toolThis paper implements an adoptive Neuro-fuzzy interface system (ANFIS) to actualize an efficient model for prediction of cutting forces during conventional milling with minimum average test error.

This paper presents an efficient optimization method of combining off-line optimization with on-line adaptive control for CNC (Computerized Numerical Control) machining parameter, and develops the corresponding system, aims to multi-

sheet metal english wheel

sheet metal engraving machine

SOLIDWORKS 3D allows you to quickly create sheet metal part designs using a simple design process, saving you time and development costs, thanks to specific sheet metal features. We can use these features to create sheet metal designs with several different methods.

adaptive control system in cnc machines pdf|adaptive control systems