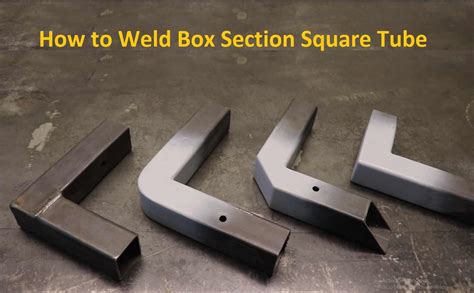

how to weld mild steel box section Here's some tips on cutting, welding and finishing steel box corners to a seamless finish. Merchandise: http://urchfab.com/merchandise/Support the channel: h. Find the most affordable replacement parts for your CNC machines now. We carry parts from the top manufacturers in the industry to allow for a true one-stop shop experience. Discover some of the top categories that our customers purchase from. Discover this week's featured deals and save money on your needed parts.

0 · welding for mild steel

1 · welding box section corners

2 · mild steel welding process

3 · mild steel welders

4 · mild steel after welding

5 · how to weld box corners

6 · cutting metal box sections

7 · cutting aluminum box section

Computer Numerical Control (CNC) machines have revolutionized the manufacturing industry, offering precision, efficiency, and versatility. From creating intricate designs to heavy-duty cutting, there's a CNC machine .

Here's some tips on cutting, welding and finishing steel box corners to a seamless finish. Merchandise: http://urchfab.com/merchandise/Support the channel: h.Welding Techniques for Mild Steel. Choosing the Right Process: The most common welding processes for mild steel are MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas). MIG is often preferred for its speed and ease, especially . Table of design properties for steel square profiles / square hollow sections (SHS) according to Eurocode 3 including cross-section dimensions & design resistance. Calculate your stresses and moments here (filling in the . Learn the basics for MIG welding mild steel with your Millermatic® MIG welder. What is MIG welding? MIG welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into .

A beginner's guide to welding mild steel, including MIG and arc welding options. Suitable for first time users and DIY enthusiasts.

Stick welding mild steel is one of the easiest ways to learn to weld. Mild steel is a forgiving metal that is great for practicing on. Stick welding or arc welding, while not as easy as MIG welding, is relatively easy and suitable for a . Master the art of welding hardened steel to mild steel with these expert techniques and tips. Learn how to tackle challenges, choose the right methods, and achieve strong, durable welds every time.

Mig Welding GMAW Steel Box Tube. Straight line splice weld. Penetration cut & reveal. The Metal Fab Guy. 15.5K subscribers. Subscribed. 646. 50K views 3 years ago. Detailing Metal workshop.illustrating the design of structural hollow sections for beams and columns in buildings. All the examples were prepared by Miss M E Brettle and checked by Mr A S Malik of The Steel . Yep corten steel, I've plated holes in the side with normal mild steel and my mig and its been no problem. Also fitted lock boxes and never had a issue. They all get painted up again, roofs covered with bitumin paint. There not going to see salt I've got next week off so it'll give me time to practice before I start blowing holes through the roofs.Robust Structural Solutions for Commercial and Industrial Applications with Mild Steel Box Section. . Easy Welding & Fabrication: The composition of our box sections using Mild Steel and other similar materials makes them ideal for .

welding for mild steel

I've got a 5ft wide gap (between 2x40ft shipping containers) and I'd like to build a walkway over it. I was going to use 100x50x3mm hollow box section in 5ft lengths, stood on its narrow side giving a 100mm wall, spaced every 1.5ft. I'm struggling to find a way to calculate how much weight a single span could hold. The formula is for a point load. I is the "second moment of area", i.e. how much the beam resists bending. And E is young modulous, a fixed number that depends on the grade of the steel. The E number I used below must be for regular mild steel.The welding of Hollow Structural Sections (HSS) does have some unique features. Unlike open sections, where welding is typically possible from both sides of an element, welding of HSS is only possible from one side, thus requiring larger weld sizes. . particularly for the longitudinal welds in “matched box” connections as in Fig. 2, are .

I just aquirred several large H beams with 5/8" webbing. I'm seriously considering building a break the bend 1/4" mild steel plate 8' wide. This would be just the ticket to form up the fire box and eliminate several weld seams. Chances are even at your "delayed" rate of progress, you'll have yours done first. Post pictures!!I have a question regarding trying to stick weld thin mild steel. I have been trying to weld up a work bench and I am not a very experienced welder, the frame is made of 1.8mm rectangular hollow section, I have had a great deal of trouble welding it without blowing holes through it, I reduce the amperage to try to eliminate this and then have all kinds of trouble striking an arc . Mild Steel Box Section 40 x 40 x 3mm | TOTAL TO ORDER = 9000 mm (9 meters) Mild Steel Flat Bar 40 x 5 mm | TOTAL TO ORDER = 7000 mm (7 metres) . It’s ok to weld a small section of a join, then move onto the next section then return to the original join later. Doing this will reduce the amount of heat going into the metal and stop it from . I have some 50 x 50mm x 2.5mm mild steel box section that I need to bend in to a 45 degree bend. Anyone have any idea ? Just heat it up?

Look no further than the Mild Steel Box Section Steel Square Tube by Speciality Metals. Available in various lengths, this cost-effective option is an excellent choice for a wide range of applications. . MIG (Metal Inert Gas) Welding: This is a common method for welding mild steel. It provides strong welds, is efficient and is suitable for .

I am new to welding, but would eventually like to be able to weld my classic cars. Meanwhile, I have a project in mind, for a vice bench. It will be constructed out of 40mm mild steel box section (3mm thick), with some 3mm mild steel plate as shelves. So, the plan is to be welding mild steel, 1mm-3mm thick to start with. Here is my criteria:

Would 25x25x2.5 mild steel box section slide inside 30x30x2.5? Would the seam get in the way? . For telescoping box sections I like to use sizes that gives plenty of clearance and then weld washers every few inches onto the outside of the smaller box to give a smooth a sliding action, that way if it's too tight you only have to sand the . Hi, Can someone help me out as to what amperage to use to TIG weld 10mm mild plate to 3mm box section? I've got 1.6mm electrodes and 1.6mm mild steel filler rods. Planning on using 5lpm argon.. Are there any usefull techniques? Cheers, Paul.

41 kobalt stainless steel tool box

Our Mild Steel Box Section is highly receptive to cutting, drilling and welding, it complements the variety of projects box section is commonly used for. Combining the resilience of the box structure with the strength, formability and versatility of steel; it offers a very reliable and long lasting finished product which is also widely recycled . Arc welding 3mm sheet steel. Thread starter GeorgeB; Start date Aug 10, 2008; 1; 2; Next. 1 of 2 . In the first image, I joined two pieces of angle iron to make a bit of box section, to hold a wooden handle. . 2mm rods in a .Our mild steel box section can be used for a large range of various applications. These applications include, construction, structures, frames, furniture, transport, security grills and general fabrication. . Welding properties are good and good results can be achieved. Much like rectangular hollow section, square hollow section can be used .

4438 steel outlet boxes

Master the art of welding hardened steel to mild steel with these expert techniques and tips. Learn how to tackle challenges, choose the right methods, and achieve strong, durable welds every time. . This method is . Mitre vs butt joint, mild steel box section. Thread starter smashweld; Start date Feb 16, 2017; S. smashweld Member. Messages 764 Location Central Scotland. . On a butt weld on box section has a gap as the corners are curved . Rig Pig Member. Messages 3,742 Location Narrwich! U.K. Feb 16, 2017 Hello I am new to MIG welding and have been making my own gym equipment using mild steel box section tubing. Most of the connections for this equipment comprise of 10mm plate welded to 3mm thick box section ends to allow for bolt/nut securement.

Order Your Mild Steel Box Section From Metals4U . Buy mild steel box section from metals4U. We are the UK’s leading online metal supplier, and we stock an extensive collection of mild steel box section in different grades and sizes. When you order with us, you can take advantage of next-day delivery and bulk discounts.Hi all, I need to attach some hinges to 25x25x2.5mm mild steel box section. I will be sending it off for powder coating too. My question is: do I weld the hinges to the box section, remove the hinge pins, then powder coat the whole lot.We offer FREE standard delivery on Mild Steel orders over £500+VAT and Engineering Bar and Tube Clamp products for orders over £300 ex VAT. Delivery is 2/5 days on all mild steel and engineering steel products standard and cut. 48Hour Delivery available on most standard length orders but will depend on the delivery address provided. The welded area must then be cleaned with a wire brush to remove any dirt or debris from the surface before beginning the welding process. Once prepped, use a mild steel electrode (E6013 or E7018 Rod) with an appropriate amperage range for your particular application to ensure maximum strength and durability of the welded joint.

Our mild steel box section can be used for a large range of various applications. These applications include, construction, structures, frames, furniture, transport, security grills and general fabrication. . Welding properties are good and good results can be achieved. Much like rectangular hollow section, square hollow section can be used .1. Thin steel. I used 1/8" steel from a local scrap yard. The amount depends on the size of box you want. 2. MIG welding equipment. 3. Plasma cutter or other tool to cut the metal pieces. 4. Welding helmet, gloves, long pants, long sleeve shirt, closed toed shoes. 5. Various clamps. 6. Sander. 7. Soap stone marker, measuring tape, square ruler. 8.

welding box section corners

The frame is braced by angle-iron cross members and has a sturdy, ply wooden deck. It’s best to use not less than 5-ply 12 mm minimum — in this case we have used 7-ply 17 mm. With minor variations, I have built a standard 1200 mm x 1800 mm (6ft by 4ft ) domestic trailer with a solid frame of rectangular hollow section (RHS) mild steel. I work with wood and metal and I am making a project using 6mm mild steel bar. To give an idea it may end up like a spiders web. I wish to weld the bar in different configurations ie. a tee shape Y shape a v shape etc. I have an old arc welder buzz box which works well enough when I get it going.

mild steel welding process

If it’s in a handhole, it doesn’t need to be spliced via direct burial methods. It is not considered direct burial. It is considered spliced inside a junction box rated for a wet location, and inside the handhole is considered a wet location. Therefore, any splicing method listed for a wet location is sufficient.

how to weld mild steel box section|mild steel after welding