sheet metal gusset forming tool See more at: http://www.goengineer.com or http://www.goengineer.com/products/solidworks/ or http://www.goengineer.com/govideochannel/Learn how to create a sh. Discover the differences between plastic and metal electrical enclosures. Learn which material best suits your needs based on durability, cost, and environmental factors.Under my driver seat, there is a black box with some wires going to it. It's under the seat on the left(closes side to door). You can kind of move it around slightly but it seems .

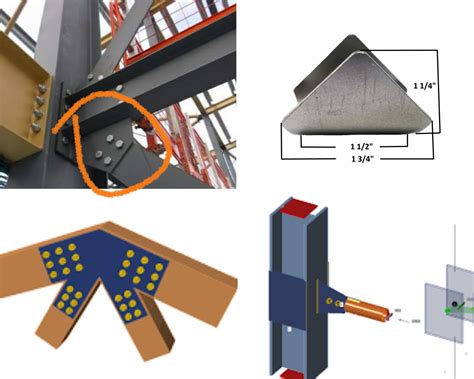

0 · triangular gusset

1 · solidworks sheet metal gusset tool

2 · sheet metal gussets

3 · sheet metal gusset tool

4 · sheet metal gusset shape

5 · sheet metal gusset repair

Metal fabrication is the process of making metal materials into various end products. The process can include bending, cutting, and assembling raw metal stock to form .

A sheet metal gusset is an indented feature that forms a gusset to stiffen a bend in sheet metal part. Rather than using a custom-made forming tool, SOLIDWORKS includes a Sheet Metal Gusset tool. In this tutorial, we'll take a . In this video, we dive into the Forming Tool and Gusset commands, essential for creating complex and robust s. See more at: http://www.goengineer.com or http://www.goengineer.com/products/solidworks/ or http://www.goengineer.com/govideochannel/Learn how to create a sh.Sheet metal gussets are formed with special tooling which has a ridge going across the v opening. The punch is split to the left and right of the ridge as to not be damaged while forming. The sheet metal is bent normally across the v .

How to Use Forming Tool, Sheet Metal Gusset, Simple Hole and Vent in Soildworks Chapter from Solidworks 2018 Tutorial For Beginners Subject for Mechanical En. Sheet metal gussets are formed with special tooling which has a ridge going across the v opening. . This triangular section is known as a gusset and can be used to .

Gusset a Sheet Metal Bend. It is quite common to find a gusset of sorts in the corner (bend region) of sheet metal parts to stiffen the part. To accomplish this, we'll create a custom form tool (or copy the one attached) to .Choose from our selection of sheet metal forming tools, including sheet metal crimpers and shapers, sheet metal benders, and more. In stock and ready to ship.

You can create sheet metal gussets with specific indents that go across bends. To add sheet metal gussets: Click Sheet Metal Gusset (Sheet Metal toolbar) or Insert > Sheet Metal > Sheet . The SOLIDWORKS Sheet Metal Gusset tool can quickly add various size and shaped gussets to your bent parts. Learn how the tool works in this tech tip. we will learn sheet metal basic features like Base flange, Edge Flange, sheet metal gusset , hole wizard and Extruded Cut in Solidworks sheet metal.1)Solidwo.

With hardened rollers and precision-machined gears, these rolling mills stand up to heavy use. They’re often used to compress sheets to an uncommon gauge size, convert scrap metal into sheets or wire, or create different thicknesses in a single piece of metal without welding multiple pieces together. One and a half inch spacing center to center 5/16 width of the gusset and then add material thickness to get the outside width of the gusset. The tooling c.Click Sheet Metal Gusset (Sheet Metal toolbar) or Insert > Sheet Metal > Sheet Metal Gusset.; In the Sheet Metal Gusset PropertyManager, under Position, select:. The bend face or two planar faces that are adjacent to a bend. The edge to be used as a reference. This can be any linear entity in order to specify the alignment of the gusset.

Sheet Metal Gusset PropertyManager. Use the Sheet Metal Gusset PropertyManager to create sheet metal gussets with specific indents across bends. Sheet Metal Tabs. The depth of a tab feature is automatically set to the thickness of the sheet metal part. The direction of the depth automatically coincides with the sheet metal part to prevent a . Welcome to our SolidWorks Sheet Metal tutorial! In this video, we dive into the Forming Tool and Gusset commands, essential for creating complex and robust s.

Sheet metal gussets are provided to avoid unbending the Sheet metal part under load conditions.In this video, we will learn how to design a gusset in Creo pa.

DVD hướng dẫn thiết kế kim loại tấm (Sheet metal) trên SolidWorks: http://bit.ly/2VgcusH[hoccokhi] Hướng dẫn dùng forming tool trong sheet metal . 👉 https://amzn.to/3M85SVuIn this SolidWorks Sheet Metal Tutorial, learn how to use forming tools to create complex sheet metal parts effectively. This tutorial provides a step-by-step guide on applying forming tools to design intricate shapes, bends, and cuts commonly used in manufacturing. Whether a beginner or a professional, this video .Using Forming Tools with Sheet Metal: Sheet Metal Parts: Multibody Sheet Metal Parts: Using Sheet Metal Bend Parameters: Simulation: . Weldments and Structure System: Troubleshooting: Glossary: Sheet Metal Gusset PropertyManager. Use the Sheet Metal Gusset PropertyManager to create sheet metal gussets with specific indents across bends. To .

triangular gusset

Press brake forming-The fundamental advantage of a press brake as a forming tool is its flexibility. By using standard vee-dies, cost savings can be realized through economical set-ups . Critical Dimensions Sheet Metal Forming – Outside dimension should be used unless the inside dimension is critical. - 3 -

Exercise 17: Sheet Metal Trailer; Lesson 6: Forming Tools and Gussets. Sheet Metal Forming Tools. How They Work; Types of Forming Tools; Standard Forming Tools. The Forming Tools Folder; Using a Standard Forming Tool; Form Tool Feature Settings; Form Tool Features in the Flat; Part Document Properties; Custom Forming Tools; Split Line; Forming .or another heat treatable metal with good ductility may need to be used. The part may require heat-treating after forming to achieve necessary stiffness or spring performance characteristics, which adds to manufacturing cost. Note that broad flat sections in high carbon spring steel parts tend to warp during heat treating. Where potential warpingWilson Tool provides a wide range of tool solutions for Bending, Punching and Stamping customers around the globe. We are best known for more than 57 years of customized tooling solutions designed to help customers resolve their most challenging fabrication issues.

Table of Contents. 1 Standard Press Brake Tooling Examples; 2 Examples of Non-Manufacturable Formed Parts ; 3 3 Options for Projects Requiring Non-Standard Press Brake Tooling . 3.1 Custom tooling; 3.2 Cut .

Hello guys, I'm having difficulty in creating a dart in sheet metal. My reference to a dart is a strenghtening crease to a right angled wall. There are no pre-defined form features of this sort in the library. Is there an easy way to generate one. T I A SW 2005 sp4 How to Use Forming Tool, Sheet Metal Gusset, Simple Hole and Vent in Soildworks Chapter from Solidworks 2018 Tutorial For Beginners Subject for Mechanical En.I'm gonna choose this one here, keep it 1.25, and now we've got the tool exactly how we want it, but now we have to convert this into a sheet metal forming tool. So right up here is forming tool.45° gussets shouldn’t be designed to be more than 4 times material thickness on their flat edge; For holes, the distance between the gusset and the hole’s edge should be at least 8 times material thickness. Hems. Hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to touch.

Displays the forming tool's placement sketch in a flat pattern. Show form tool centers when flattened: Displays the forming tool's center mark where the forming tool is located in a flat pattern. Show sheet metal gusset profiles when flattened: Displays gusset profiles when you flatten a sheet metal part.Using Forming Tools with Sheet Metal: Sheet Metal Parts: Multibody Sheet Metal Parts: Using Sheet Metal Bend Parameters: Simulation: SimulationXpress: Sketching: . Use the Sheet Metal Gusset PropertyManager to create sheet metal gussets with specific indents across bends. To open the Sheet Metal Gusset PropertyManager, click Sheet Metal .

Click Sheet Metal Gusset (Sheet Metal toolbar) or Insert > Sheet Metal > Sheet Metal Gusset.; In the Sheet Metal Gusset PropertyManager, under Position, select:. The bend face or two planar faces that are adjacent to a bend. The edge to be used as a reference. This can be any linear entity in order to specify the alignment of the gusset.

Sheet metal design skills are a crucial tool in any engineer’s toolbox, but given how little attention sheet metal design gets in academia, most skills are learned on the job. . A basic (single axis) bend is the most foundational sheet metal forming operation. Despite the relative simplicity of the bending process, there is a lot to .Using Forming Tools with Sheet Metal: Sheet Metal Parts: Multibody Sheet Metal Parts: Using Sheet Metal Bend Parameters: Simulation: SimulationXpress: Sketching: . Use the Sheet Metal Gusset PropertyManager to create sheet metal gussets with specific indents across bends. To open the Sheet Metal Gusset PropertyManager, click Sheet Metal .

solidworks sheet metal gusset tool

Sheet metal forming tools, like stamping presses, play an ubiquitous role in the manufacture of several products. With increasing requirements of quality and efficiency, ensuring maximum uptime of .

Click Sheet Metal Gusset (Sheet Metal toolbar) or Insert > Sheet Metal > Sheet Metal Gusset.; In the Sheet Metal Gusset PropertyManager, under Position, select:. The bend face or two planar faces that are adjacent to a bend. The edge to be used as a reference. This can be any linear entity in order to specify the alignment of the gusset.Bead tool is used to create an embossed or engraved bead on sheet metal part using single entity or a set tangentially connected entities.Gussets are rib l.

Metal stamping is an incredibly versatile and efficient manufacturing process that takes flat metal sheets or coils and transforms them into precisely shaped and intricate parts. By utilizing force, pressure, and specialized tooling, components with diverse forms — including bends, curves, cutouts, and embossing, are possible.

sheet metal gusset forming tool|sheet metal gusset repair