conductor spacing in a junction box You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For . We use only Mill Procured and USA Processed sheet metal materials for commercial use. All of our metal fabrication is done in the USA and Most is done in house at our Fort Myers Florida fabricating shop and ship product to anywhere within the United States.

0 · nec junction box sizing guide

1 · nec junction box size limits

2 · nec junction box requirements

3 · nec junction box grounding requirements

4 · junction box sizing requirements

5 · junction box sizing

6 · junction box size calculator

7 · electrical junction box size

Western Sheet Metal, 2406 Hinton Dr, Irving, Texas, 75061 Office: 972-438-7742 Fax: 972-438-2996 Email: [email protected] Email: [email protected]. Hours: Monday – Friday 8am – 4:30pm

nec junction box sizing guide

You need to determine the correct horizontal dimension, vertical dimension, and spacing between the raceways containing the same conductors. If you follow the steps laid out in Sizing Steps, you'll find this easy to do.You must size pull boxes, junction boxes, and conduit bodies large enough so a .

cantex 5133709u junction box

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For . When electrical cables route from box to box, you must leave at least six inches of free conductor wiring in the junction box for connection . How to Size a Junction Box (18 AWG to 6 AWG) If the conductors in your junction box are of size 18 AWG through 6 AWG, you’ll use the tables in NEC 314.16 to determine the minimum volume of your junction box. For your .

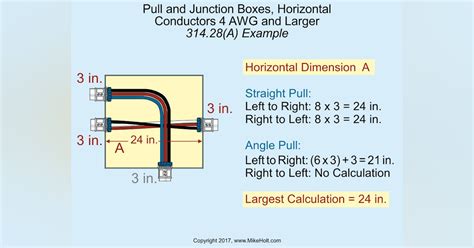

For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per 314.28. That means the minimum dimensions of boxes and conduit bodies must comply with . Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.

Determine the number and type of conductors entering and exiting the box. Include all devices, such as switches, receptacles, or splices, that will be housed within the junction box. According to NEC 314.16 (B), calculate the box fill .Boxes and conduit bodies enclosing conductors larger than 6 AWG, under 600 volts, must meet the installation requirements in 314.28. Boxes containing conductors 4 AWG or larger, under 600 volts, are calculated from the sizes .Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to .

You need to determine the correct horizontal dimension, vertical dimension, and spacing between the raceways containing the same conductors. If you follow the steps laid out in Sizing Steps, you'll find this easy to do. For example, a box that contains three to six conductors requires a minimum volume of 18 cubic inches, while a box that contains seven or eight conductors requires a minimum volume of 20 cubic inches. Section 370-29 outlines the requirements for junction boxes used in hazardous locations. You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28. When electrical cables route from box to box, you must leave at least six inches of free conductor wiring in the junction box for connection purposes. In article 300.14, this technique is explained.

How to Size a Junction Box (18 AWG to 6 AWG) If the conductors in your junction box are of size 18 AWG through 6 AWG, you’ll use the tables in NEC 314.16 to determine the minimum volume of your junction box. For your convenience, the tables are reproduced here.For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per 314.28. That means the minimum dimensions of boxes and conduit bodies must comply with the following: Straight pulls. Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.Determine the number and type of conductors entering and exiting the box. Include all devices, such as switches, receptacles, or splices, that will be housed within the junction box. According to NEC 314.16 (B), calculate the box fill units based on the conductor sizes and types. Each conductor, device, and fitting has a specific fill unit value.

Boxes and conduit bodies enclosing conductors larger than 6 AWG, under 600 volts, must meet the installation requirements in 314.28. Boxes containing conductors 4 AWG or larger, under 600 volts, are calculated from the sizes and numbers of raceways.Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to contact . You need to determine the correct horizontal dimension, vertical dimension, and spacing between the raceways containing the same conductors. If you follow the steps laid out in Sizing Steps, you'll find this easy to do.

For example, a box that contains three to six conductors requires a minimum volume of 18 cubic inches, while a box that contains seven or eight conductors requires a minimum volume of 20 cubic inches. Section 370-29 outlines the requirements for junction boxes used in hazardous locations. You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28. When electrical cables route from box to box, you must leave at least six inches of free conductor wiring in the junction box for connection purposes. In article 300.14, this technique is explained. How to Size a Junction Box (18 AWG to 6 AWG) If the conductors in your junction box are of size 18 AWG through 6 AWG, you’ll use the tables in NEC 314.16 to determine the minimum volume of your junction box. For your convenience, the tables are reproduced here.

For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per 314.28. That means the minimum dimensions of boxes and conduit bodies must comply with the following: Straight pulls. Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.Determine the number and type of conductors entering and exiting the box. Include all devices, such as switches, receptacles, or splices, that will be housed within the junction box. According to NEC 314.16 (B), calculate the box fill units based on the conductor sizes and types. Each conductor, device, and fitting has a specific fill unit value.Boxes and conduit bodies enclosing conductors larger than 6 AWG, under 600 volts, must meet the installation requirements in 314.28. Boxes containing conductors 4 AWG or larger, under 600 volts, are calculated from the sizes and numbers of raceways.

nec junction box size limits

nec junction box requirements

cantilever steel cash box with coin tr

nec junction box grounding requirements

Contact Us - Leading Metal Fabricators since 1948 | William A. Schmidt and Sons

conductor spacing in a junction box|nec junction box sizing guide