introduction to sheet metal layout and processes principles used to determine layouts for sheet metal fittings. Includes practice layout and fabrication tasks that allow trainees to develop and demonstrate their skills. Factory-Style Shell Boxes. These are the perfect fit for your loads and they are priced right so you can organize ALL of your loads. We stock standard Factory sizes for almost every gauge and length. Our boxes are sized just like those from the big ammo factories.

0 · sheet metal work process

1 · sheet metal production process

2 · sheet metal parts design guide

3 · sheet metal manufacturing guide pdf

4 · sheet metal making process

5 · sheet metal design process

6 · sheet metal design and manufacturing

7 · how to design sheet metal

18 gauge is fine for most American 1950s-1960s cars. I don't know about '30s-'40s cars. You would not want to go thinner. I've used 20-gauge (thinner) for small areas but that was for convenience. All my patch panels and such are 18-gauge.

Working with sheet metal is not a simple task. It usually involves multiple steps and processes to achieve the desired part geometry. The main challenge of sheet metal design is to choose the .Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with .The family of manufacturing processes used to create sheet metal components encompasses a diverse range of techniques, each tailored to achieve specific shapes, sizes, and features with precision and efficiency.

Geomiq's Sheet Metal design guide helps you with your design process to accelerate production time and reduce production costs.

principles used to determine layouts for sheet metal fittings. Includes practice layout and fabrication tasks that allow trainees to develop and demonstrate their skills.This course covers the essential basic theoretical and practical knowledge required for Designing Sheet metal parts aimed at Design engineers who are designing products. The common .Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques.

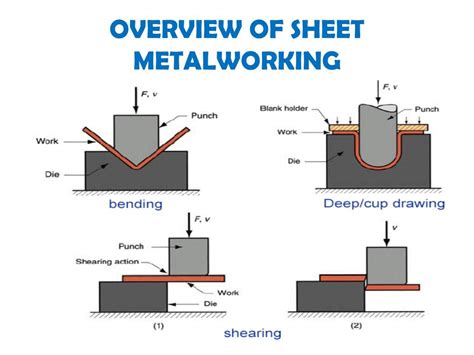

The sheet metal design process involves conceptualizing, drawing, and creating detailed plans for cutting, shaping, and joining metal. It’s all about turning metal sheets into durable, functional, and aesthetic products for various industries, .Objectives. By the end of today you should be able to. .describe different forming processes, when they might be used, and compare their production rates, costs and environmental . 5. Introduction (CONTD.) • The Progressive die or transfer die is dependent on size, complexity and volume of production. Progressive die stamping is used to produce a large number of parts and keep the costs as . I. INTRODUCTION P roduction of progressive die from a workpiece follows . piercing, notching, blanking, coining, shaving, drawing, and forming, are carried out on the sheet metal strip. The output is a complete workpiece at each stroke of the press. . research studies stated were either focused on design, process scheduling or mechanization .

Get an introduction to sheet metal fabrication. This section explains the sheet metal fabrication process, how precision sheet metal fabrication differs, the main advantages and disadvantages, as well as its common applications. . During .

sheet metal work process

Benefits of Sheet Metal Design. Versatility: – Sheet metal is used in every industry at some level as it is versatile; users might not even recognize a product as being made of sheet metal like aluminum foil. Sheet metal is the material used for the construction of industrial machines and equipment but there are other uses of sheet metal too.Uncover insights on the sheet metal fabrication process with CADDi Drawer. Explore our guide and enhance your manufacturing efficiency—read more now! . Procurement 101: An Introduction to Sheet Metal Fabrication Process. . No tooling required so fast design changes are possible. More expensive per part than mechanical cutting. Plasma Cutting.

metallic enclosures

Sheet metal fabrication is the process of turning flat sheet metals, typically 0.15 mm to 10 mm thick, into parts and structures of various shapes. . Introduction to Sheet Metal Fabrication. Like. . 11. Sheet Metal operations Introduction Sheet metal formingis a grouping of many complementary processes that are used to form sheet metal parts. One or more of these processes is used to take a flat sheet of ductile metal, and mechanically apply deformation forces that alter the shape of the material. Before deciding on the processes, one should determine . Introduction to Sheet metal design. Look around yourself, and you will realize there is an abundance of products made of sheet metal. Be it consumer products such as beverage cans, cookware, file cabinets, or industrial products such as car bodies, frames, and exhausts. . There are various other processes for sheet metal design that may or .

INTRODUCTION TO SHEET METAL FORMING PROCESSES - SimTech . simulationStudy with Quizlet and memorize flashcards containing terms like During the layout process, it is important to be able to, Always start your layout on a piece of sheet metal in the, The primary sheet metal layout method that is used to create a pattern for any fitting in which the opposite lines are parallel to each other is called and more. The software suite caters to various needs in sheet metal fabrication, including material optimization, tool arrangements, CAD import and design, planning and simulation, and cutting optimization. With its agnostic approach, Flux seamlessly integrates with diverse hardware and software platforms commonly used in the industry.

sheet metal production process

- Joining processes and their comparison - Design Guidelines to create cost- effective designs which are suitable for manufacturing. - Design projects So if you are a student exploring the world of product design or a design engineer who wants to make products with sheet metal then this courses will be a good value addition.Introduction to Sheet Metal Sheet Metal tool allows the designer to quickly create sheet metal part designs using simple design process and helps on saving time and development costs and increases productivity. In this chapter, we will be discussing about Sheet Metal features like base flange, conversion of part into sheet metal, edge flange .

Subsequently, the sheet metal is cutted in a normal shear process at the same position of the sheet metal where the notch at first was pressed into the bottom of the sheet.Precision sheet metal workers commonly fabricate and install gutters, sheet metal roofs, and louvers on new buildings. False; Architectural sheet metal worker. Apprenticeship programs for sheet metal workers last about four to five years. True. A(n)_____ tests the newly installed HVAC systems for proper air flow.

Layout and Fabrication of Sheet Metal and Fiberglass Duct Topics 1.0.0 Tools and Equipment . . so the processes you learn here can be applied to roofing, flashing, and exterior . Introduction to Types and Identification of Metal . NAVEDTRA 14250A 13-2.

In the manufacturing industry, the sheet metal process is common, and sheet metal parts are used in many different industries, including consumer products, appliances, aircraft, and the automotive and aerospace sectors. .Sheet Metal Work. Design for Forming Principles and Practices. XIII. Manufacturing - Machining Processes . Introduction to Mechanical Design and Manufacturing. Powder Metal Processes Powder metallurgy is the process of manufacturing parts using metal powders. Composites can also be generated by combining metal powder with nonmetals, commonly .

Basic Principles. Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and form the sheets into the final part. Introduction. Sheet metal forming technology has undergone a significant transformation in recent years, driven by advancements in materials, processes, and design tools. Today, engineers and designers have access to a vast array of innovative techniques that enable them to create complex and intricate sheet metal parts with unprecedented .

Introduction To Sheet Metal Fabrication Products J. Beddoes,M. Bibby Principles and Methods of Sheet Metal Fabrication George Sachs,2013-09 Sheet Metal Fabrication Eddie Paul,2008-03-15 Sheet metal fabrication--from fins and fenders to art--with all the necessary information on tools, preparations, materials, forms, mock-ups, and much more.

sheet metal parts design guide

Layout Tools l l l The LAYOUT of metal is the procedure of measuring and marking material for cutting, drilling, or welding. Most cases use shop drawings, sketches, and blueprints to obtain the measurements required to fabricate the job.Lesson: Introduction to Sheet Metal 5 Bend Allowances Defined The following list describes items to consider when working with bend allowances. Bend allowances can vary from shop to shop and machine to machine. Bend allowances can vary with the type of material. Bend allowances can vary depending on whether the bend is going with or against the grain of

Overview of the sheet metal design process. The first step of sheet metal fabrication is understanding & knowing the kind of design that is required on the sheet metal. This is essential for the .Sheet Metal Forming Simulation. Kuang-Hua Chang, in Product Manufacturing and Cost Estimating Using Cad/Cae, 2013. 4.2.1 Sheet Forming Processes. In a sheet forming process, a thin piece of metal sheet, commonly referred to as the blank, is bent or stretched by tools into a desired shape without excessive thinning, tearing, or wrinkling.Here we present a brief .

Introduction: The Importance of Efficient Sheet Metal Layout In the world of manufacturing, sheet metal fabrication plays a crucial role across diverse industries, from automotive and . The efficiency of the sheet metal layout process directly impacts production costs, material waste, and overall project timelines. A well-planned layout .

metallic copper fabric buy in bulk

metallic fabric hat

Sheet metal screws are used to fasten two pieces of sheet metal together, or to connect sheet metal to other types of metal, such as tubing. These screws typically have a round head, flat head, or even a hex head.

introduction to sheet metal layout and processes|sheet metal making process