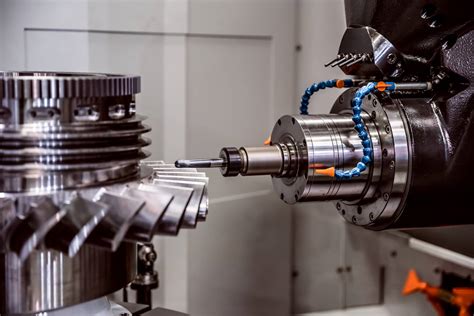

aircraft parts cnc machining CNC machining is a cornerstone of aerospace manufacturing, providing the precision, efficiency, and versatility required to produce the high-quality components essential for modern aircraft and spacecraft. Our mild steel box section can be used for construction, frames, structures, security grills and more, and you can get it custom cut to meet the most detailed specifications. We work with tradespeople, contractors, and keen hobbyists to supply the highest quality steel box section quickly and efficiently.

0 · precision cnc machining

1 · aircraft cnc machining

2 · aerospace machining

3 · aerospace cnc parts

4 · aerospace cnc milling machine

5 · aerospace cnc manufacturing

6 · aerospace cnc machining explained

7 · aerospace cnc machining

RS-232 communication quality, especially with FANUC's implementation of xon/xoff, depends upon the FIFO depth of the RS-232 device's UART. In the case of USBRS-232 conversion, the RS-232 UART is embedded within the USB chip, so the FIFO is a feature of the USB chipset.

This sophisticated manufacturing process combines the power of computer numerical control (CNC) technology with advanced machining techniques to create intricate parts and assemblies essential for the functionality, safety, and . CNC machining is a cornerstone of aerospace manufacturing, providing the precision, efficiency, and versatility required to produce the high-quality components essential for modern aircraft and spacecraft.This sophisticated manufacturing process combines the power of computer numerical control (CNC) technology with advanced machining techniques to create intricate parts and assemblies essential for the functionality, safety, and reliability of modern aircraft and spacecraft. CNC machining is a cornerstone of aerospace manufacturing, providing the precision, efficiency, and versatility required to produce the high-quality components essential for modern aircraft and spacecraft.

What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, components, and assemblies which are essential for crafts used in the aerospace industry. CNC machining is a critical process in the aerospace industry for producing high-quality parts with tight tolerances and high precision. It offers several benefits, including improved efficiency, accuracy, speed, and reliability in producing aerospace components.

Precision CNC machining is pivotal in making high-quality aerospace components. The aerospace sector has strict safety controls and high production standards for CNC machining aerospace parts. These parts require the tightest and highest tolerances, dimensions, and performance for every component. Parts or components for commercial aircraft, military jets, satellites, and missiles must tolerate severe and variable temperatures and altitude pressures to work effectively. CNC machining is one production technique that guarantees the production of mission-critical, safe, and dependable parts. In this article, we highlight aerospace CNC machining, including its . In the vast realm of manufacturing, aerospace CNC machining stands distinct, epitomizing precision and technological sophistication. As aircraft and spacecraft continue to push boundaries, the role of Computer Numerical Control (CNC) .CNC machining plays a crucial role in creating intricate and complex aircraft components such as engine parts, landing gear, and structural elements. The precision and accuracy of CNC machines enable the production of intricate designs that are vital for the performance and safety of aircraft.

In the aerospace industry, CNC machining plays a crucial role in producing high-precision components for aircraft and spacecraft. CNC (Computer Numerical Control) technology is used to automate the manufacturing of complex parts, ensuring accuracy and consistency in every piece.CNC machining helps companies like SpaceX, NASA and Blue Origin to design, process and manufacture aerospace components from start to finish. Whether it’s manufacturing the outer shell of a rocket or the smallest component of a jet engine, CNC machining delivers the high level of precision needed.This sophisticated manufacturing process combines the power of computer numerical control (CNC) technology with advanced machining techniques to create intricate parts and assemblies essential for the functionality, safety, and reliability of modern aircraft and spacecraft. CNC machining is a cornerstone of aerospace manufacturing, providing the precision, efficiency, and versatility required to produce the high-quality components essential for modern aircraft and spacecraft.

What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, components, and assemblies which are essential for crafts used in the aerospace industry.

precision cnc machining

aircraft cnc machining

CNC machining is a critical process in the aerospace industry for producing high-quality parts with tight tolerances and high precision. It offers several benefits, including improved efficiency, accuracy, speed, and reliability in producing aerospace components. Precision CNC machining is pivotal in making high-quality aerospace components. The aerospace sector has strict safety controls and high production standards for CNC machining aerospace parts. These parts require the tightest and highest tolerances, dimensions, and performance for every component.

Parts or components for commercial aircraft, military jets, satellites, and missiles must tolerate severe and variable temperatures and altitude pressures to work effectively. CNC machining is one production technique that guarantees the production of mission-critical, safe, and dependable parts. In this article, we highlight aerospace CNC machining, including its .

In the vast realm of manufacturing, aerospace CNC machining stands distinct, epitomizing precision and technological sophistication. As aircraft and spacecraft continue to push boundaries, the role of Computer Numerical Control (CNC) .CNC machining plays a crucial role in creating intricate and complex aircraft components such as engine parts, landing gear, and structural elements. The precision and accuracy of CNC machines enable the production of intricate designs that are vital for the performance and safety of aircraft.In the aerospace industry, CNC machining plays a crucial role in producing high-precision components for aircraft and spacecraft. CNC (Computer Numerical Control) technology is used to automate the manufacturing of complex parts, ensuring accuracy and consistency in every piece.

aerospace machining

can you make a metal building into a house

$1.00

aircraft parts cnc machining|aerospace cnc machining explained