fabrication processes of metals The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and . 2023 Christmas - click here to view the Idea Book click here to view the Catalog all .

0 · your examples of fabricated parts

1 · what are fabricated metal products

2 · sheet metal assembly techniques

3 · manufacturing processes for metals

4 · manufacturing methods for metals

5 · manufacture of fabricated metal products

6 · different types of metal fabrication

7 · basic metal fabrication

You have 2 junction boxes, the battery junction box which is located under the hood on the driver's side near the brake master cylinder, and the central junction box which is located under the driver's side of the dash.

Choosing a metal fabrication method suited to a given project depends on the designed part’s geometry, the product’s intended purpose, and the materials used in crafting it. Common metal fabrication processes are as follows: 1. Casting 2. Cutting 3. Drawing 4. Folding 5. Forging 6. Extrusion 7. . See more

Choosing a custom metal fabrication shop or custom metal manufacturer that will best fulfill a project’s needs is an important decision that can affect the manufacturing rate, production quality, and cost-effectiveness of a given project. To help in the selection . See moreThis guide provides a basic understanding of metal fabrication, the different methods, and considerations for choosing a fabricator. For more . See moreThe metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and .Casting and Molding: Adding Volume to Metal Fabrication. For large-volume production, machined parts are often transitioned to casting or molding processes. Metal injection molding, or MIM, is the process whereby metal .

This work gives a comprehensive overview on fabrication processes of metal-FRP hybrid components, which are generally classified into: joining and forming, and the advantages and disadvantages of each fabrication process are reviewed to present a clear description of its application and maturity degree for industrial production. The following . Stamping is a metal fabrication process you might not think about, but it's everywhere around you. It involves pressing flat metal sheets into a desired shape or design using a stamp or die. Think about the metal parts in cars, appliances, and even your electronic devices. Many of these started as a flat sheet and were shaped through stamping.

your examples of fabricated parts

Key Processes in Metal Fabrication. Metal fabrication involves a variety of techniques that transform raw metals into finished products. These processes include cutting, stamping, welding, extrusion, forging, and casting. Each stage of the metal fabrication process is crucial in creating a final product tailored to specific requirements.The different types of metal fabrication processes are applied onto a metal raw material in order to produce metal products for a variety of uses. While some of these processes employ the use of a constant application of electrical, or heat energy, some processes simply require physical manipulation in different levels, or degrees. .A set of six-axis welding robots.. Metal fabrication is the creation of metal structures by cutting, bending and assembling processes. It is a value-added [1] process involving the creation of machines, parts, and structures from various raw materials.. Typically, a fabrication shop bids on a job, usually based on engineering drawings, and if awarded the contract, builds the product.

What are the types of metal forming processes? Bending; Stretching; Deep Drawing; Roll Forming; Extrusion; Punching; Stamping; Ironing; Hydroforming; Metal forming is a part of the metal fabrication process and is used to create structural parts or complex pieces out of metal sheets and tubing. It’s an essential procedure for a wide variety of products — without it, our . Steel manufacturing stands as a linchpin in the intricate web of the global supply chain, with a far-reaching impact on numerous industries. The steel industry, encompassing crucial facets such as steel production, steel processing, and the overall manufacturing process, is indispensable in shaping the backbone of modern infrastructure and development. However, conventional manufacturing processes face formidable limitations for the fabrication of customized implants, such as porous scaffolds for tissue engineering, which are future direction towards precise medicine. As a metal additive manufacturing technology, laser powder bed fusion (L-PBF) has the advantages of design freedom and .The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and assemblies. Sheet metal is highly compatible with the process, allowing custom sheet metal fabricators to create diverse products with optimal design versatility and .

Also known as rolling, this fabrication process involves shaping metal by passing it between rollers. If the metal is heated above its recrystallization temperature during this process, it’s termed “hot rolling”; otherwise, it’s “cold rolling”. Rolling is a prevalent metalworking method.

Metals are manipulated to create components we rely on every day. Different processes transform billets and sheets of metal into their desired shapes. Our cars, laptops, cell phones, and kitchen appliances exist because of the metal fabrication process. Metal fabrication encompasses every step needed to create a final component part or product. Metal fabrication is the creation of metal parts or structures from a variety of metal materials through different processes. The metal materials come in sheet, bar, plate, or other forms and can be made into specific shapes and dimensions. Metal fabrication needs a thorough plan and strategy to ensure the success of actual work.Metal fabrication is the backbone of many industries, from the cars we drive to the buildings we live and work in. At its core, metal fabrication is the process of creating metal structures by cutting, bending, and assembling. It’s a craft that requires precision, expertise, and an understanding of the properties and potentials of various metals. Explore the diverse world of metal manufacturing processes and discover the optimal techniques for shaping metal to meet your unique needs. 1. Roll Forming. In short, roll forming involves continually feeding a long strip of .

Metal fabrication is defined as the process of creating and building metal structures from raw metal materials. It involves cutting, shaping, bending, and molding metallic material into the desired final product. Metal-fabrication processes include everything from heavy machinery and equipment to simple hand railings. Specific processes may . Metal Casting vs. Other Manufacturing Processes. The choice of process is critical for achieving the desired balance between part complexity, efficiency, and cost. Metal casting stands out for its ability to create complex .

Extrusion: a metal forming process in which pushing the material through or around a die using a mechanical or hydraulic press, suitable for the formation of complex cross-sections in one piece of metal. Bending: a metal manufacturing process that deforms the metal to make the workpiece bed at an angle and form different shapes along a straight . However, conventional manufacturing processes face formidable limitations for the fabrication of customized implants, such as porous scaffolds for tissue engineering, which are future direction towards precise medicine. As a metal additive manufacturing technology, laser powder bed fusion (L-PBF) has the advantages of design freedom and . Generally, the metal fabrication process works in the following three steps: Step 1. Designing: A few decades ago, designing in metal projects was done on paper with diagrams. This is still followed today but only for the most basic requirements. Most metal fabricators start with a design created on a computer using a dedicated software called . Metal Manufacturing Processes. Metal parts are virtually everywhere, from the device you are reading this from to the iron beams used to hold up bridges. The many methods for making parts from metal include the following: Forging. Forging is the process wherein hot metal is subject to forced compression in order to obtain the desired shape .

Continuous Improvement in Fabrication. Fabrication processes are generally target-rich environments for continuous improvement. There are great chances for visual management and 5S to make processes run more smoothly. There are immense opportunities to reduce setup time to help lower lot sizes.

Steelmaking has played a crucial role in the development of ancient, medieval, and modern technological societies. Early processes of steel making were made during the classical era in Ancient China, India, and Rome.. Cast iron is a hard, brittle material that is difficult to work, whereas steel is malleable, relatively easily formed and a versatile material. Request PDF | Fabrication processes of metal-fiber reinforced polymer hybrid components: a review | Fascinating advantages (e.g., lightweight and superior performances combined with ductility and .

Because the metal fabrication business has applications in nearly every industry, there are many different processes and techniques that are used to create an endless variety of products. The floor of a metal fabrication shop is a diverse place full of tools for cutting, stamping, bending, hole punching, melting, coating, and more.ADVERTISEMENTS: This article throws light upon the top four techniques used in fabrication process of metals. The techniques are: 1. Casting 2. Forming 3. Machining 4. Welding. Technique # 1. Casting: Casting is perhaps the oldest known method of giving shapes to metals and alloys. When found suitable, it is the shortest route from the [.]

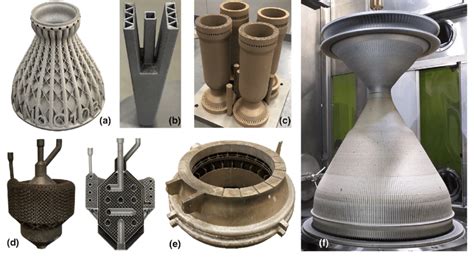

Types of Metal Fabrication Processes. There are various processes involved in metal fabrication. The specific combination of metal or stainless steel fabrication processes will vary with the geometry of the part, the type of usage it will get and what it is made of. Here are examples of some choices for different types of fabrication processes:

what are fabricated metal products

In my 1996 328is the SAP relay is located in the front power distribution box in relay position 1 (1 out of the 15 possible).

fabrication processes of metals|your examples of fabricated parts