electrical box size requirements The sizing requirements for pull boxes, junction boxes, handhole enclosures, . These different types of electrical boxes have two, three, or four openings, allowing you to install multiple switches, outlets, or a combination of both in a single package. 2-gang boxes are ideal for installations where you need two switches or outlets, while 3-gang boxes can accommodate three.

0 · types of electrical outlet boxes

1 · pull box sizing chart

2 · junction box size chart

3 · electrical pull box size chart

4 · electrical box size chart

5 · electrical box dimensions standard

6 · dimensions of electrical outlet box

7 · 1 gang electrical box dimensions

There is little difference between Stake Anvils, Stakes, T-Stakes and Bickerns. Their tapered shanks serve the same purpose, to mount the tool in a stump or tool holder. They are all .

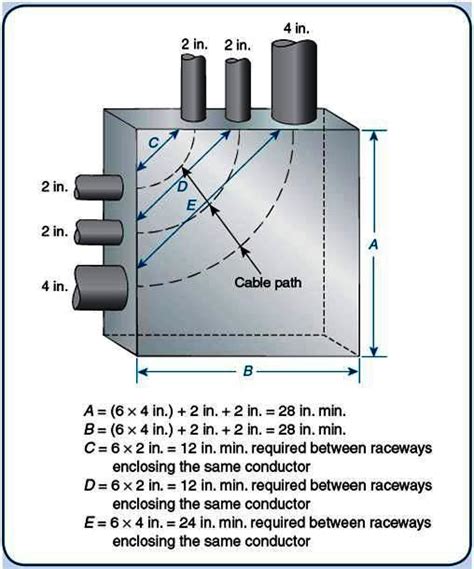

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28.

The sizing requirements for pull boxes, junction boxes, handhole enclosures, .Boxes containing 6 AWG and smaller conductors must be sized in an . The sizing requirements for pull boxes, junction boxes, handhole enclosures, and conduit bodies exist to prevent conductor insulation damage. Those requirements are in 314.28, and they apply to all conductors 4 AWG .Sizing of Junction and pull boxes according to NEC Section 314-28. Today, I will explain Electrical Boxes Volume and Fill Calculations as follows. Part (A), “Box Volume Calculations,” defines .

The NEC 2023 includes specific provisions for sizing junction boxes. These requirements ensure that boxes are large enough to accommodate conductors, splices, and other components without causing damage or excessive heat .

types of electrical outlet boxes

pull box sizing chart

Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®. You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28. The sizing requirements for pull boxes, junction boxes, handhole enclosures, and conduit bodies exist to prevent conductor insulation damage. Those requirements are in 314.28, and they apply to all conductors 4 AWG and larger ( Fig. 1 ).Sizing of Junction and pull boxes according to NEC Section 314-28. Today, I will explain Electrical Boxes Volume and Fill Calculations as follows. Part (A), “Box Volume Calculations,” defines the volume of a wiring enclosure or box.

The NEC 2023 includes specific provisions for sizing junction boxes. These requirements ensure that boxes are large enough to accommodate conductors, splices, and other components without causing damage or excessive heat buildup. Key sections to reference include: Article 314: Covers boxes, conduit bodies, and fittings. Section 314.16 specifies the minimum volume size of junction boxes required for various types of electrical conductors. The volume size of a junction box is measured in cubic inches. It is determined based on the number and size of conductors within the box. Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.

Article 314 of the National Electrical Code contains most of the key regulations that you’ll need to follow when choosing, installing and sizing junction boxes. These regulations describe in detail the required junction box size, depending on the number and size of conductors and fittings enclosed within the box.Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to contact .

junction box size chart

Boxes containing 6 AWG and smaller conductors must be sized in an approved manner to provide free space for all conductors, devices, and fittings. In no case can the volume of the box, as calculated in Sec. 314.16 (A), be less than the volume requirement as calculated in Sec. 314.16 (B). The National Electrical Code (NEC) provides guidelines for box sizing based on the number and size of wires you're working with. The NEC specifies the minimum volume of the box in cubic inches (cu. in.) that you need to accommodate your wires.

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28. The sizing requirements for pull boxes, junction boxes, handhole enclosures, and conduit bodies exist to prevent conductor insulation damage. Those requirements are in 314.28, and they apply to all conductors 4 AWG and larger ( Fig. 1 ).Sizing of Junction and pull boxes according to NEC Section 314-28. Today, I will explain Electrical Boxes Volume and Fill Calculations as follows. Part (A), “Box Volume Calculations,” defines the volume of a wiring enclosure or box.The NEC 2023 includes specific provisions for sizing junction boxes. These requirements ensure that boxes are large enough to accommodate conductors, splices, and other components without causing damage or excessive heat buildup. Key sections to reference include: Article 314: Covers boxes, conduit bodies, and fittings.

2023 pro set metal football hobby box

Section 314.16 specifies the minimum volume size of junction boxes required for various types of electrical conductors. The volume size of a junction box is measured in cubic inches. It is determined based on the number and size of conductors within the box. Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®. Article 314 of the National Electrical Code contains most of the key regulations that you’ll need to follow when choosing, installing and sizing junction boxes. These regulations describe in detail the required junction box size, depending on the number and size of conductors and fittings enclosed within the box.Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to contact .

Boxes containing 6 AWG and smaller conductors must be sized in an approved manner to provide free space for all conductors, devices, and fittings. In no case can the volume of the box, as calculated in Sec. 314.16 (A), be less than the volume requirement as calculated in Sec. 314.16 (B).

electrical pull box size chart

Let’s dive into the 5 types of welding seams below. Fillet Welded Seams. Fillet Welded Seams are just another terminology for corner, lap, and tee joints. Fillet Welded Seams are the most common type of welding joint and accounts for nearly 75% of joints made with arc welding.

electrical box size requirements|pull box sizing chart