cnc machine aerospace industry In this comprehensive guide, we’ll take a deep dive into the world of aerospace CNC machining, exploring the materials, benefits, cutting tools and strategies, surface . First cover is of the Subsistance set, which includes MGS3:SE, the Ape Escape minigame, Secret Theater, Metal Gear 1 and Metal Gear 2: Solid Snake. I'm not sure about the second one, but it says it is part of a set, so it should be part of .

0 · what is aerospace cnc machining

1 · cnc machining aerospace parts

2 · cnc aerospace parts

3 · aircraft cnc machining

4 · aerospace manufacturing cnc machining

5 · aerospace connector manufacturing machine

6 · aerospace cnc machining services

7 · aerospace cnc machine shop

Screw gauge (diameter) – The standard screw gauge for outlets (boxes and switches) is #6. Threads per inch – The standard thread count on electrical screws is 32, meaning 32 threads per inch of shaft.

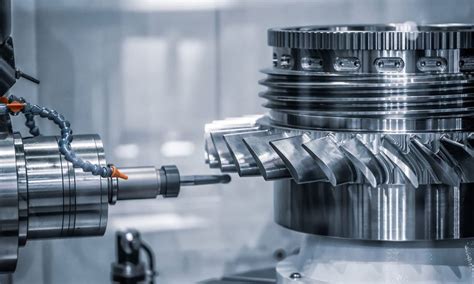

Aerospace CNC machining stands at the forefront of modern manufacturing, driving innovation in the aerospace industry through precision and efficiency. This guide delves into the intricacies of CNC machining tailored for .Aerospace CNC machining is the backbone of the aerospace industry, playing a pivotal role in the production of high-precision components that conform to strict international quality standards. This sophisticated manufacturing process . What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, . In this comprehensive guide, we’ll take a deep dive into the world of aerospace CNC machining, exploring the materials, benefits, cutting tools and strategies, surface .

CNC machining plays a vital role in various aspects of aerospace manufacturing, from prototyping to mass production. The technology enables manufacturers to create intricate and precise .

CNC machining is a critical process in the aerospace industry for producing high-quality parts with tight tolerances and high precision. It offers several benefits, including improved efficiency, accuracy, speed, and reliability . The aerospace CNC machining process involves using computer-controlled machine tools to shape raw materials, such as metals or composites, into finished aerospace components. The process starts with a digital 3D .

Fictiv provides AS9100 CNC machining services and even offers an Ultimate Guide you can use during part design. In aerospace precision machining, achieving tight tolerances is critical .In the aerospace industry, CNC machining plays a crucial role in producing high-precision components for aircraft and spacecraft. CNC (Computer Numerical Control) technology is .CNC machining delivers unrivaled precision and accuracy, ensuring that aerospace parts meet exact specifications. This is especially important for critical aerospace systems, such as turbine engines, landing gear and structural . Aerospace CNC machining stands at the forefront of modern manufacturing, driving innovation in the aerospace industry through precision and efficiency. This guide delves into the intricacies of CNC machining tailored for aerospace applications, exploring the advanced techniques, specialized materials, and stringent quality standards that ensure .

what is aerospace cnc machining

Aerospace CNC machining is the backbone of the aerospace industry, playing a pivotal role in the production of high-precision components that conform to strict international quality standards. This sophisticated manufacturing process combines the power of computer numerical control (CNC) technology with advanced machining techniques to create . What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, components, and assemblies which are essential for crafts used in the aerospace industry. In this comprehensive guide, we’ll take a deep dive into the world of aerospace CNC machining, exploring the materials, benefits, cutting tools and strategies, surface treatments, and applications that make this technology so essential to the industry.

CNC machining plays a vital role in various aspects of aerospace manufacturing, from prototyping to mass production. The technology enables manufacturers to create intricate and precise parts that meet the rigorous specifications of the aerospace industry. CNC machining is a critical process in the aerospace industry for producing high-quality parts with tight tolerances and high precision. It offers several benefits, including improved efficiency, accuracy, speed, and reliability in producing aerospace components. The aerospace CNC machining process involves using computer-controlled machine tools to shape raw materials, such as metals or composites, into finished aerospace components. The process starts with a digital 3D model .Fictiv provides AS9100 CNC machining services and even offers an Ultimate Guide you can use during part design. In aerospace precision machining, achieving tight tolerances is critical since many aircraft components belong to life-sustaining systems such as jet engines and landing gear.

In the aerospace industry, CNC machining plays a crucial role in producing high-precision components for aircraft and spacecraft. CNC (Computer Numerical Control) technology is used to automate the manufacturing of complex parts, ensuring accuracy and consistency in every piece.

CNC machining delivers unrivaled precision and accuracy, ensuring that aerospace parts meet exact specifications. This is especially important for critical aerospace systems, such as turbine engines, landing gear and structural elements, where even a slight deviation can significantly impact performance, safety and durability.

Aerospace CNC machining stands at the forefront of modern manufacturing, driving innovation in the aerospace industry through precision and efficiency. This guide delves into the intricacies of CNC machining tailored for aerospace applications, exploring the advanced techniques, specialized materials, and stringent quality standards that ensure .Aerospace CNC machining is the backbone of the aerospace industry, playing a pivotal role in the production of high-precision components that conform to strict international quality standards. This sophisticated manufacturing process combines the power of computer numerical control (CNC) technology with advanced machining techniques to create .

oem abs junction box supplier

What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, components, and assemblies which are essential for crafts used in the aerospace industry. In this comprehensive guide, we’ll take a deep dive into the world of aerospace CNC machining, exploring the materials, benefits, cutting tools and strategies, surface treatments, and applications that make this technology so essential to the industry.CNC machining plays a vital role in various aspects of aerospace manufacturing, from prototyping to mass production. The technology enables manufacturers to create intricate and precise parts that meet the rigorous specifications of the aerospace industry.

oee calculation for cnc machines

CNC machining is a critical process in the aerospace industry for producing high-quality parts with tight tolerances and high precision. It offers several benefits, including improved efficiency, accuracy, speed, and reliability in producing aerospace components. The aerospace CNC machining process involves using computer-controlled machine tools to shape raw materials, such as metals or composites, into finished aerospace components. The process starts with a digital 3D model .Fictiv provides AS9100 CNC machining services and even offers an Ultimate Guide you can use during part design. In aerospace precision machining, achieving tight tolerances is critical since many aircraft components belong to life-sustaining systems such as jet engines and landing gear.

In the aerospace industry, CNC machining plays a crucial role in producing high-precision components for aircraft and spacecraft. CNC (Computer Numerical Control) technology is used to automate the manufacturing of complex parts, ensuring accuracy and consistency in every piece.

cnc machining aerospace parts

cnc aerospace parts

Depending on the pattern and type of sheet metal, you can use several different kinds of equipment to make a cut. You can use an electric saw for simple lines, or you can try tin snips, dremels, or metal nibblers for complex designs with curved lines.

cnc machine aerospace industry|aerospace connector manufacturing machine