countersinking sheet metal Choose from a variety of standard countersink options, which can either be formed or machined into sheet part parts. Machined countersinks are created with a drill press and formed countersinks are made with punch press tooling—the . What Does CNC Machining Stand For? CNC Machining stands for Computer Numerical Control Machining, a technology that revolutionized the manufacturing industry by automating the .

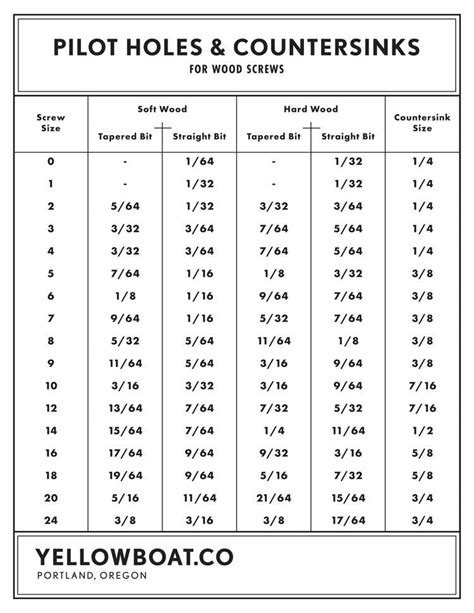

0 · what size countersink chart

1 · countersinking screws in metal

2 · countersink size for #8 screw

3 · countersink size chart metal

4 · best countersinks for metal

5 · 90 degree countersink chart

6 · 82 vs 100 degree countersink

7 · 100 deg countersink dimension chart

Zero Skateboards is a skateboard company located in Carlsbad, California, United States. The brand was founded by professional skateboarder and entrepreneur Jamie Thomas, and distributed by his Black Box Distribution company.

Countersinks are conical holes cut or formed into precision sheet metal parts that allow hardware to sit flush with the material. Here’s everything .Choose from a variety of standard countersink options, which can either be formed or machined into sheet part parts. Machined countersinks are created with a drill press and formed countersinks are made with punch press tooling—the .Our countersinking process ensures that every hole is perfectly shaped and sized for its intended hardware. This precision not only enhances the aesthetic appeal of your parts but also .Choose from a variety of standard countersink options, which can either be formed or machined into sheet part parts. Machined countersinks are created with a drill press and formed countersinks are made with punch press tooling—the .

Countersinking is a method of creating a conical hole in a sheet metal piece, allowing for the flush attachment of fasteners like screws or bolts. Important: Larger countersinks in thinner .

In this article, we’ll cover how to design a part that successfully leverages our countersinking capabilities for your design. To show how you can save time on post- laser operations, we’ll also bend and powder coat the part .Find design guidelines for your CAD files to specify countersinking in your sheet metal & composite parts. Major/Minor depth charts & more.

Discover the secrets to creating perfect countersink holes in sheet metal with our easy-to-follow guide, designed for beginners and pros!From cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet metal. This article will explore what countersink holes are, their uses, and how to apply ANSI standards to create . Countersinks are conical holes cut or formed into precision sheet metal parts that allow hardware to sit flush with the material. Here’s everything you need to know about designing countersinks, including Approved Sheet Metal’s proprietary formula for getting countersinks right every time. 2.1 1. Machined countersinks. 2.2 2. Formed countersinks.Choose from a variety of standard countersink options, which can either be formed or machined into sheet part parts. Machined countersinks are created with a drill press and formed countersinks are made with punch press tooling—the best .

what size countersink chart

Our countersinking process ensures that every hole is perfectly shaped and sized for its intended hardware. This precision not only enhances the aesthetic appeal of your parts but also significantly improves their functionality and fit.Choose from a variety of standard countersink options, which can either be formed or machined into sheet part parts. Machined countersinks are created with a drill press and formed countersinks are made with punch press tooling—the best . Countersink holes and countersink compatible fasteners are used in all sorts of products and projects. From cellphones and computers to industrial equipment and cabinets, countersinking is used for machining metal stock, wood, sheet-metal, and even PCBs.

Countersinking is a method of creating a conical hole in a sheet metal piece, allowing for the flush attachment of fasteners like screws or bolts. Important: Larger countersinks in thinner materials will enlarge the inner hole diameter. In this article, we’ll cover how to design a part that successfully leverages our countersinking capabilities for your design. To show how you can save time on post- laser operations, we’ll also bend and powder coat the part so it arrives ready to install, right out of that shrink-wrapped packaging.Find design guidelines for your CAD files to specify countersinking in your sheet metal & composite parts. Major/Minor depth charts & more.Discover the secrets to creating perfect countersink holes in sheet metal with our easy-to-follow guide, designed for beginners and pros!

From cellphones to industrial equipment, countersinking plays a key role in machining metal, wood, and sheet metal. This article will explore what countersink holes are, their uses, and how to apply ANSI standards to create precise, flush finishes in manufacturing.

Countersinks are conical holes cut or formed into precision sheet metal parts that allow hardware to sit flush with the material. Here’s everything you need to know about designing countersinks, including Approved Sheet Metal’s proprietary formula for getting countersinks right every time. 2.1 1. Machined countersinks. 2.2 2. Formed countersinks.

Choose from a variety of standard countersink options, which can either be formed or machined into sheet part parts. Machined countersinks are created with a drill press and formed countersinks are made with punch press tooling—the best .Our countersinking process ensures that every hole is perfectly shaped and sized for its intended hardware. This precision not only enhances the aesthetic appeal of your parts but also significantly improves their functionality and fit.

china sheet metal laser cutting machine manufacturers

Choose from a variety of standard countersink options, which can either be formed or machined into sheet part parts. Machined countersinks are created with a drill press and formed countersinks are made with punch press tooling—the best . Countersink holes and countersink compatible fasteners are used in all sorts of products and projects. From cellphones and computers to industrial equipment and cabinets, countersinking is used for machining metal stock, wood, sheet-metal, and even PCBs.Countersinking is a method of creating a conical hole in a sheet metal piece, allowing for the flush attachment of fasteners like screws or bolts. Important: Larger countersinks in thinner materials will enlarge the inner hole diameter.

china precision parts machining

In this article, we’ll cover how to design a part that successfully leverages our countersinking capabilities for your design. To show how you can save time on post- laser operations, we’ll also bend and powder coat the part so it arrives ready to install, right out of that shrink-wrapped packaging.Find design guidelines for your CAD files to specify countersinking in your sheet metal & composite parts. Major/Minor depth charts & more.Discover the secrets to creating perfect countersink holes in sheet metal with our easy-to-follow guide, designed for beginners and pros!

countersinking screws in metal

countersink size for #8 screw

Box 14 — Employers can use W-2 box 14 to report information like: A member of the clergy’s parsonage allowance and utilities Any charitable contribution made through payroll deductions

countersinking sheet metal|countersink size chart metal