axis in cnc turning machine Using an X, Y or Z code in a CNC program tells the machine to go to a specific location along those axes. Location changes can be in one or more axes. If only a Z axis . Thinking about building a simple but sturdy shop lathe stand from 2x4s and plywood? This design has turning blank storage, drawers, and even a pull out shelf for a grinder. If you’ve been watching my shop you’ll know I brought a lathe into the shop and just temporarily set it on one of my workbenches.

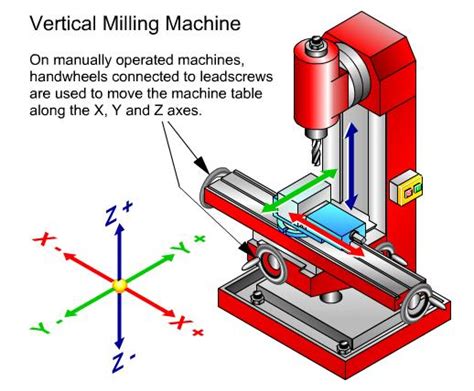

0 · milling machine axis diagram

1 · cnc mill axis diagram

2 · cnc machine axis locations diagram

3 · cnc machine axis direction

4 · cnc lathe axis explained

5 · cnc lathe axis diagram

6 · cnc axis chart

7 · axis identification in cnc machine

$1,159.00

If you’re wondering how many axis in cnc lathe machine, here’s a quick overview: 2-axis: Basic turning operations. 3-axis: Adds live tooling for milling, drilling, and tapping.

Using an X, Y or Z code in a CNC program tells the machine to go to a specific location along those axes. Location changes can be in one or more axes. If only a Z axis . Turning is a subtractive machining process that uses a cutting tool to remove material for creating cylindrical parts. The tool itself moves along the axis of the machined part .

To achieve ultimate precision in CNC machining, linear and rotary axes play a crucial role. Linear axes provide linear movement in addition to the primary X, Y, and Z axes, enabling versatility .

There are three primary axes on a CNC lathe: the X-axis, Z-axis, and sometimes the C-axis. X-Axis: The X-axis is the horizontal axis that runs parallel to the bed of the lathe. It controls the movement of the cutting tool . Typically, CNC lathes come with 2 axes as standard, while CNC milling machines come with 3 axes as standard. However, the number of axes in a CNC system can vary, with some lathes capable of 6-axis linkage or even . In this complete guide to 4 Axis CNC Machining, you’ll learn when to use one, how they work, 4 Axis CNC workholding, Programming, and 4 Axis for CNC Routers.CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth).

In this guide, we’ll discuss how CNC machines are able to make complex shapes using multiple axes of travel, how these directions are defined, and what that means for your product development goals. In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better.

If you’re wondering how many axis in cnc lathe machine, here’s a quick overview: 2-axis: Basic turning operations. 3-axis: Adds live tooling for milling, drilling, and tapping.

milling machine axis diagram

cnc mill axis diagram

wickes stainless steel bathroom cabinet

Using an X, Y or Z code in a CNC program tells the machine to go to a specific location along those axes. Location changes can be in one or more axes. If only a Z axis coordinate is given then the machine will only move in the Z axis. This is . Turning is a subtractive machining process that uses a cutting tool to remove material for creating cylindrical parts. The tool itself moves along the axis of the machined part while the part is rotating, creating a helical toolpath.To achieve ultimate precision in CNC machining, linear and rotary axes play a crucial role. Linear axes provide linear movement in addition to the primary X, Y, and Z axes, enabling versatility and detailed control over cutting operations.

There are three primary axes on a CNC lathe: the X-axis, Z-axis, and sometimes the C-axis. X-Axis: The X-axis is the horizontal axis that runs parallel to the bed of the lathe. It controls the movement of the cutting tool along the length of the workpiece. Typically, CNC lathes come with 2 axes as standard, while CNC milling machines come with 3 axes as standard. However, the number of axes in a CNC system can vary, with some lathes capable of 6-axis linkage or even controlling more than 10 axes. The exact number of axes is determined by the system’s function. How many CNC lathes are there? In this complete guide to 4 Axis CNC Machining, you’ll learn when to use one, how they work, 4 Axis CNC workholding, Programming, and 4 Axis for CNC Routers.

CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth). In this guide, we’ll discuss how CNC machines are able to make complex shapes using multiple axes of travel, how these directions are defined, and what that means for your product development goals.

In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better.

If you’re wondering how many axis in cnc lathe machine, here’s a quick overview: 2-axis: Basic turning operations. 3-axis: Adds live tooling for milling, drilling, and tapping. Using an X, Y or Z code in a CNC program tells the machine to go to a specific location along those axes. Location changes can be in one or more axes. If only a Z axis coordinate is given then the machine will only move in the Z axis. This is . Turning is a subtractive machining process that uses a cutting tool to remove material for creating cylindrical parts. The tool itself moves along the axis of the machined part while the part is rotating, creating a helical toolpath.

To achieve ultimate precision in CNC machining, linear and rotary axes play a crucial role. Linear axes provide linear movement in addition to the primary X, Y, and Z axes, enabling versatility and detailed control over cutting operations. There are three primary axes on a CNC lathe: the X-axis, Z-axis, and sometimes the C-axis. X-Axis: The X-axis is the horizontal axis that runs parallel to the bed of the lathe. It controls the movement of the cutting tool along the length of the workpiece. Typically, CNC lathes come with 2 axes as standard, while CNC milling machines come with 3 axes as standard. However, the number of axes in a CNC system can vary, with some lathes capable of 6-axis linkage or even controlling more than 10 axes. The exact number of axes is determined by the system’s function. How many CNC lathes are there? In this complete guide to 4 Axis CNC Machining, you’ll learn when to use one, how they work, 4 Axis CNC workholding, Programming, and 4 Axis for CNC Routers.

CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth).

wickes metal roofing sheets

cnc machine axis locations diagram

Unistrut P1973 HG U Shaped Bracket - P1973-HG (Options: Hot-Dipped Galvanized) Note: When used for mechanical supports, load capacities of brackets, fittings and other supporting elements should be in compliance with the American Standard Code for Pressure Piping.

axis in cnc turning machine|cnc machine axis locations diagram