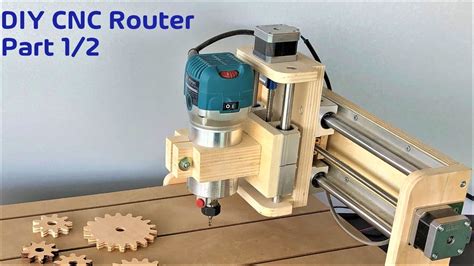

building cnc machine This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal . The TEKNO PRIME is a CNC milling machine, particularly suitable for the production of doors and frames on an industrial scale and specifically for the milling of paumelle hinges, plates and locks, beyond handle holes and keyholes.

0 · homemade cnc router machine

1 · homemade cnc machine plans

2 · do it yourself cnc machine

3 · build your own cnc router

4 · build your own cnc mill

5 · build your own cnc machine

6 · build your own cnc kit

7 · build your own cnc

Metal screws differ from wood screws in their design and specific function, featuring design elements geared toward fastening metal-based materials and hard plastics. Metal screws feature longer threads than wood screws, usually at least two inches in length.

This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal . Part one concentrates on the hardware involved – the steppers, drivers, and controller. He starts with one of those all-in-one eBay packages, .

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know. Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY guide will walk you through how to easily make your own CNC machine.This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine. I include all of the necessary steps I went through in designing and building this CNC milling machine. Part one concentrates on the hardware involved – the steppers, drivers, and controller. He starts with one of those all-in-one eBay packages, although he did upgrade the motion controller to a.

homemade cnc router machine

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.What type of CNC router do you want to build? There basically are two types of CNC routers: the moving table design and the moving gantry design. Moving table style designs are often used for smaller size CNC routers. Let’s dive into the nitty-gritty of creating a DIY CNC machine from scratch. Before diving headfirst into the world of CNC machinery, here are some key aspects you need to take into account: Purpose and Usage: What will you use your CNC machine for? Engraving, cutting, milling, or perhaps 3D printing?

caulk for electrical boxes

To build a CNC machine, it's essential to have a solid understanding of how they work. In this section, we will explain the basic principles of CNC machines, including the role of stepper motors, linear motion systems, and control software. My objective for this project was to design and build a CNC milling machine without the need for any machining of the parts. Ordinarily, building a mill requires a much bigger mill to get. Read through this write-up and learn how to build a DIY CNC machine by yourself from scratch. What's On This Page? Why Build Your Own CNC Machine? Building a DIY CNC router machine can be more beneficial than purchasing one. Let's run through some of the reasons: 1. Save Money.Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. This

homemade cnc machine plans

Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY guide will walk you through how to easily make your own CNC machine.This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine. I include all of the necessary steps I went through in designing and building this CNC milling machine. Part one concentrates on the hardware involved – the steppers, drivers, and controller. He starts with one of those all-in-one eBay packages, although he did upgrade the motion controller to a.

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.What type of CNC router do you want to build? There basically are two types of CNC routers: the moving table design and the moving gantry design. Moving table style designs are often used for smaller size CNC routers.

Let’s dive into the nitty-gritty of creating a DIY CNC machine from scratch. Before diving headfirst into the world of CNC machinery, here are some key aspects you need to take into account: Purpose and Usage: What will you use your CNC machine for? Engraving, cutting, milling, or perhaps 3D printing?To build a CNC machine, it's essential to have a solid understanding of how they work. In this section, we will explain the basic principles of CNC machines, including the role of stepper motors, linear motion systems, and control software.

My objective for this project was to design and build a CNC milling machine without the need for any machining of the parts. Ordinarily, building a mill requires a much bigger mill to get.

Read through this write-up and learn how to build a DIY CNC machine by yourself from scratch. What's On This Page? Why Build Your Own CNC Machine? Building a DIY CNC router machine can be more beneficial than purchasing one. Let's run through some of the reasons: 1. Save Money.

cctv junction box toolstation

do it yourself cnc machine

ced plastic electrical box

ceag junction box certificate

CNC routing is perfect for cutting a wide variety of composites, acrylics, and wood. Our machines are able to achieve sharp edges and tight tolerances on materials that would be otherwise affected by the heat of a laser.

building cnc machine|homemade cnc machine plans