arc weld sheet metal Precision welding methods are preferable like pulsed gas metal arc welding (GMAW-P), short-circuiting transfer gas metal arc welding (GMAW), pulsed GTAW, and gas . Many people are concerned that black roofs may make their homes hotter during the summer months. To understand this concern, we need to explore the science behind how roof color affects temperature. The color of an .

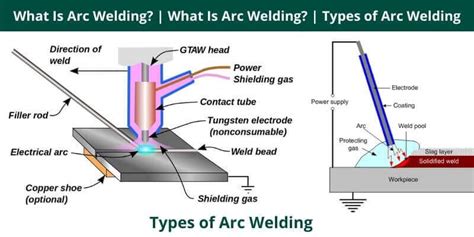

0 · types of arc welding

1 · shielded metal arc welding meaning

2 · metal arc welding diagram

3 · manual metal arc welding

4 · how to arc weld for beginners

5 · arc welding procedure step by

6 · arc welding is powered by

7 · arc welding for dummies

Wiegmann manufactures innovative customizable steel and nonmetallic electrical enclosures for OEM, commercial and MRO markets. This historic brand is part of the Commercial Construction business of Hubbell Incorporated.

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc . Can a stick welder weld thin sheet metal? Find out the limitations and the minimum thickness you can arc weld and the best methods of welding sheet metals. Seam welding, or fillet welding, is one of the most common methods we use at Approved Sheet Metal. This arc welding method uses a . Precision welding methods are preferable like pulsed gas metal arc welding (GMAW-P), short-circuiting transfer gas metal arc welding (GMAW), pulsed GTAW, and gas .

When welding sheet metal, precise control and attention to detail are vital for successful welds. Understanding the distinct approaches of MIG and TIG welding is essential for working with materials like steel or aluminum, .

Understanding the Stick Welding and Its Benefits for Sheet Metal. Stick welding, also known as shielded metal arc welding (SMAW), is a versatile and widely used welding process that involves the use of an electrode coated . Stick welding sheet metal can be done by welding DC electrode negative with 20-40A which is about the the lowest amperage settings that still allows to strike an arc. Suitable electrodes are E6011 for rusty or painted surfaces or E6013 for clean surfaces. Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make. Can a stick welder weld thin sheet metal? Find out the limitations and the minimum thickness you can arc weld and the best methods of welding sheet metals.

Seam welding, or fillet welding, is one of the most common methods we use at Approved Sheet Metal. This arc welding method uses a filler rod to create a continuous weld across the entire seam of the pieces being joined. Precision welding methods are preferable like pulsed gas metal arc welding (GMAW-P), short-circuiting transfer gas metal arc welding (GMAW), pulsed GTAW, and gas tungsten arc welding (GTAW). When welding sheet metal, precise control and attention to detail are vital for successful welds. Understanding the distinct approaches of MIG and TIG welding is essential for working with materials like steel or aluminum, commonly used . Understanding the Stick Welding and Its Benefits for Sheet Metal. Stick welding, also known as shielded metal arc welding (SMAW), is a versatile and widely used welding process that involves the use of an electrode coated in flux to join metals.

homak security first watch gun steel security cabinet

GMAW is one of the most effective ways to join thin sheets of metal like austenitic stainless steel or carbon steel. The gauge materials often have a thickness of 18-ga to 0.1875-in for the stainless steel or -24-ga to 0.1875-in for the carbon steel. Minimizing burn-through and distortion is essential to obtaining a good weld when gas metal arc welding thin-gauge materials. Gas metal arc welding (GMAW) is an effective method for joining light-gauge metals such as carbon steel and austenitic stainless steel. Stick welding of sheet metal shall be carried out using AWS A5.1/A5.1M E6013 (CWB/CSA W48-06 E4313) type electrode of diameter 5/64 inch or 2.0 mm. E6013 types electrode offer very good arc stability, easy-to-start arc, shallow penetration, and less power in arc compared to E6010 or E7018 type rods. E6013 can be used with AC, DCEP, and DCEN .

Stick welding sheet metal can be done by welding DC electrode negative with 20-40A which is about the the lowest amperage settings that still allows to strike an arc. Suitable electrodes are E6011 for rusty or painted surfaces or E6013 for clean surfaces. Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make. Can a stick welder weld thin sheet metal? Find out the limitations and the minimum thickness you can arc weld and the best methods of welding sheet metals.

Seam welding, or fillet welding, is one of the most common methods we use at Approved Sheet Metal. This arc welding method uses a filler rod to create a continuous weld across the entire seam of the pieces being joined.

Precision welding methods are preferable like pulsed gas metal arc welding (GMAW-P), short-circuiting transfer gas metal arc welding (GMAW), pulsed GTAW, and gas tungsten arc welding (GTAW). When welding sheet metal, precise control and attention to detail are vital for successful welds. Understanding the distinct approaches of MIG and TIG welding is essential for working with materials like steel or aluminum, commonly used . Understanding the Stick Welding and Its Benefits for Sheet Metal. Stick welding, also known as shielded metal arc welding (SMAW), is a versatile and widely used welding process that involves the use of an electrode coated in flux to join metals.GMAW is one of the most effective ways to join thin sheets of metal like austenitic stainless steel or carbon steel. The gauge materials often have a thickness of 18-ga to 0.1875-in for the stainless steel or -24-ga to 0.1875-in for the carbon steel.

Minimizing burn-through and distortion is essential to obtaining a good weld when gas metal arc welding thin-gauge materials. Gas metal arc welding (GMAW) is an effective method for joining light-gauge metals such as carbon steel and austenitic stainless steel.

types of arc welding

shielded metal arc welding meaning

holley hi-ram sheet metal top

Effective methods of improving WiFi signal in steel-framed buildings include the application of mesh networks, the installation of WiFi repeaters, and proper placement and orientation of the router away from metal objects and appliances.

arc weld sheet metal|metal arc welding diagram