cnc jewelry wax machine Created specifically for jewelry modeling on the Mira Mill family of machines, . Box springs are not really needed anymore as most mattresses are self supporting (a lot of meat inside) - best used with an adjustable base or platform. You can't really use a metal bed frame for a bed in the box mattresses if the slats are more than 2 inches apart.

0 · What Is CNC Machining For Jewelry Making

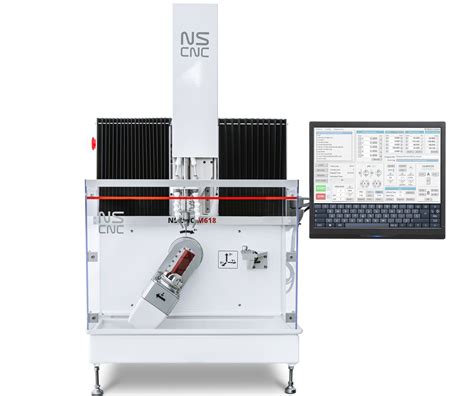

1 · Precision 5

2 · Mira 6S – nscnc.com

3 · Jewelry Workflow – nscnc.com

4 · JCAM – nscnc.com

5 · How CNC Machines are Used to Make Elegant Jewelry

6 · CNC machining for Jewelry (Compare to 3D printing)

7 · CNC Milling vs. 3D Printing

8 · CNC Machining in the Jewelry Industry: Techniques

9 · Benchtop CNC Milling Machines

The Mazak HTC-400 CNC Horizontal Mill is a robust machining center designed to deliver precision and efficiency in manufacturing processes. This machine is renowned for its high-performance capabilities, offering a range of features that cater to various machining needs.

What Is CNC Machining For Jewelry Making

custom metal lunch boxes wholesale

Precision 5

Mira 6S is a high-precision machine having a resolution of less than a micron. This gives it the opportunity to mill jewelry molds with the smallest details and achieve a completely glossy .Jewelry designers use CAD to give life to their ideas in the form of 3D models for .Created specifically for jewelry modeling on the Mira Mill family of machines, .

Jewelry designers use CAD to give life to their ideas in the form of 3D models for the ultimate in design and creativity! Ideas are given form when they are milled from a raw wax work-piece, .Created specifically for jewelry modeling on the Mira Mill family of machines, JewelryCAM’s simplicity and speed set it above traditional programs. This game-changing technology .Roland DG is at the forefront of desktop and benchtop 3D production with compact CNC milling machines that deliver precise results on a wide variety of applications, from subtractive rapid prototyping, rapid manufacturing, hobby, .

CNC machining, a swiftly emerging prototyping process, has revolutionized the jewelry industry and has become an integral part of jewelry design. In this article, we will explore how CNC machining is used in the entire jewelry . In which we share information on NC CNC 5-axis mills for precision jewellery milling, and their CNC toolpath generator plugin for Rhino 3D.

custom metal vehicle parts

CNC technology has also improved traditional jewelry making techniques, such as lost wax casting and electroforming. These methods enable the creation of intricate and complex designs, with CNC machines ensuring a .CNC Milling Machines. Milling machines use rotary cutting tools to carve a jewelry model from a block of wax, allowing jewelers to touch up or refine their models before casting. The number . Given the circular geometry of most jewelry from rings to bracelets, CNC lathes are a natural fit for jewelry applications. Advanced CNC mini-lathes allow experienced jewelers to .Mira 6S is a high-precision machine having a resolution of less than a micron. This gives it the opportunity to mill jewelry molds with the smallest details and achieve a completely glossy surface of the model. All 5-axis machines in the Mira series .

Instead of hand carving pieces from wax, makers use CNC machines. If a wax copy of a jewelry piece is created with CNC technology, it may allow more complex and precise geometries to be produced compared to a hand-carved piece. For example, engraved details can be .Jewelry designers use CAD to give life to their ideas in the form of 3D models for the ultimate in design and creativity! Ideas are given form when they are milled from a raw wax work-piece, and then cast into precious metals and set with dazzling stones!Created specifically for jewelry modeling on the Mira Mill family of machines, JewelryCAM’s simplicity and speed set it above traditional programs. This game-changing technology requires no special programming knowledge — in fact, it’s not much different from your office printer.

Roland DG is at the forefront of desktop and benchtop 3D production with compact CNC milling machines that deliver precise results on a wide variety of applications, from subtractive rapid prototyping, rapid manufacturing, hobby, craft and jewelry making, to producing medical and dental prosthetics.

CNC machining, a swiftly emerging prototyping process, has revolutionized the jewelry industry and has become an integral part of jewelry design. In this article, we will explore how CNC machining is used in the entire jewelry manufacturing process, from design to flawless production.

In which we share information on NC CNC 5-axis mills for precision jewellery milling, and their CNC toolpath generator plugin for Rhino 3D.

CNC technology has also improved traditional jewelry making techniques, such as lost wax casting and electroforming. These methods enable the creation of intricate and complex designs, with CNC machines ensuring a higher level of .

CNC Milling Machines. Milling machines use rotary cutting tools to carve a jewelry model from a block of wax, allowing jewelers to touch up or refine their models before casting. The number of axes in the machine can vary, with three- and four-axis . Given the circular geometry of most jewelry from rings to bracelets, CNC lathes are a natural fit for jewelry applications. Advanced CNC mini-lathes allow experienced jewelers to carve or engrave detailed designs into pieces of metal jewelry.Mira 6S is a high-precision machine having a resolution of less than a micron. This gives it the opportunity to mill jewelry molds with the smallest details and achieve a completely glossy surface of the model. All 5-axis machines in the Mira series .Instead of hand carving pieces from wax, makers use CNC machines. If a wax copy of a jewelry piece is created with CNC technology, it may allow more complex and precise geometries to be produced compared to a hand-carved piece. For example, engraved details can be .

Jewelry designers use CAD to give life to their ideas in the form of 3D models for the ultimate in design and creativity! Ideas are given form when they are milled from a raw wax work-piece, and then cast into precious metals and set with dazzling stones!

Created specifically for jewelry modeling on the Mira Mill family of machines, JewelryCAM’s simplicity and speed set it above traditional programs. This game-changing technology requires no special programming knowledge — in fact, it’s not much different from your office printer.Roland DG is at the forefront of desktop and benchtop 3D production with compact CNC milling machines that deliver precise results on a wide variety of applications, from subtractive rapid prototyping, rapid manufacturing, hobby, craft and jewelry making, to producing medical and dental prosthetics.CNC machining, a swiftly emerging prototyping process, has revolutionized the jewelry industry and has become an integral part of jewelry design. In this article, we will explore how CNC machining is used in the entire jewelry manufacturing process, from design to flawless production.

In which we share information on NC CNC 5-axis mills for precision jewellery milling, and their CNC toolpath generator plugin for Rhino 3D. CNC technology has also improved traditional jewelry making techniques, such as lost wax casting and electroforming. These methods enable the creation of intricate and complex designs, with CNC machines ensuring a higher level of .

CNC Milling Machines. Milling machines use rotary cutting tools to carve a jewelry model from a block of wax, allowing jewelers to touch up or refine their models before casting. The number of axes in the machine can vary, with three- and four-axis .

The battery hold down is a metal bracket that keeps the battery in place and prevents it from sliding or moving during normal vehicle operation. Typically, it is positioned over the top of the battery, securing it to the battery tray or frame of the vehicle.

cnc jewelry wax machine|What Is CNC Machining For Jewelry Making