electrical j-box in walk-in coolers Good call Peter D. I usually use expandable foam. I push the straw as far down the conduit as I can and slowly pull it out as I press the button. If not the difference in temperature will cause moisture to drip into the j-box. PVC and other outdoor electrical junction boxes will develop interior moisture due to condensation. This is minor and not to be a concern. Weep holes are not necessary. Installing a hole at the lowest point in an underground run will have the reverse effect. It will allow water into the conduit when there is sufficient groundwater. It's not a .

0 · wiring for walk in cooler

1 · walk in cooler wiring requirements

2 · walk in cooler troubleshooting

3 · walk in cooler drilling

4 · preferred wiring method for walk in coolers

5 · electric walk in cooler problems

Vintage Weis Gray Metal File Box, Monroe Michigan, 6.5 x 4 Inches, Vintage Storage

wiring for walk in cooler

Good call Peter D. I usually use expandable foam. I push the straw as far down the conduit as I can and slowly pull it out as I press the button. If not the difference in temperature . What type of wiring methods do you normally install/accept in walk-in coolers & freezers (Restaurant/grocery facilities) ? The majority I see are wired with EMT, but I see a mix .

walk in cooler wiring requirements

What is the preferred wiring method for inside walk in coolers and freezers? I generally see a couple of methods used, that being, some wired entirely with liquid tight .

Good call Peter D. I usually use expandable foam. I push the straw as far down the conduit as I can and slowly pull it out as I press the button. If not the difference in temperature will cause moisture to drip into the j-box.

What type of wiring methods do you normally install/accept in walk-in coolers & freezers (Restaurant/grocery facilities) ? The majority I see are wired with EMT, but I see a mix of compression and set-screw fittings, standard boxes and bell boxes, etc.

What is the preferred wiring method for inside walk in coolers and freezers? I generally see a couple of methods used, that being, some wired entirely with liquid tight flexible metal conduit [LFMC] and others with EMT and rain tight fittings.

The walk-in cooler’s electrical system should be grounded to prevent the buildup of static electricity and reduce the risk of electrical shock. This can be achieved by properly connecting the ground wire to the grounding system in accordance with local electrical codes. are you allowed to install standard 4in sq j boxes in a walkin cooler or are we supposed to install bell or fs type boxes? That would be a damp location and a standard 4 sq. is listed and rated as dry location only. Fitting shallow or fitting deep check listing.

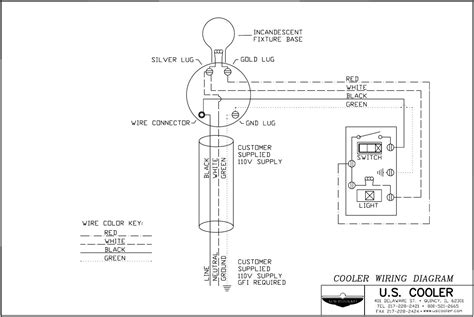

The bases for the LED light fixture is connected to the junction box which contains the electrical leads that are prewired to the electrical components contained in the door sections. Determine exactly where the power is to be brought into the junction box.

walk in cooler troubleshooting

CoolBot Walk-in coolers use a Kason 1967-A3 light switch with a built-in thermometer. The Cooler Switch, thermometer and light fixture have been PRE-WIRED at the factory through the door frame.The wiring of a walk-in cooler involves various electrical components that work together to provide power and control the cooling system. These components include the main electrical panel, circuit breakers, power cables, control switches, temperature sensors, and lighting fixtures.All OUTLET BOXES and JUNCTION BOXES installed should be surface mount. On outdoor coolers, electrical installations should be done ONLY AFTER your outdoor membrane has been installed. All walk-in freezers should have a receptacle for the heat trace to be plugged into so that the condensate will actually drain rather than freeze. I have installed several (a long time ago, in a galaxy far, far away) of these and all have been GFCI protected.

Good call Peter D. I usually use expandable foam. I push the straw as far down the conduit as I can and slowly pull it out as I press the button. If not the difference in temperature will cause moisture to drip into the j-box. What type of wiring methods do you normally install/accept in walk-in coolers & freezers (Restaurant/grocery facilities) ? The majority I see are wired with EMT, but I see a mix of compression and set-screw fittings, standard boxes and bell boxes, etc. What is the preferred wiring method for inside walk in coolers and freezers? I generally see a couple of methods used, that being, some wired entirely with liquid tight flexible metal conduit [LFMC] and others with EMT and rain tight fittings.

The walk-in cooler’s electrical system should be grounded to prevent the buildup of static electricity and reduce the risk of electrical shock. This can be achieved by properly connecting the ground wire to the grounding system in accordance with local electrical codes.

are you allowed to install standard 4in sq j boxes in a walkin cooler or are we supposed to install bell or fs type boxes? That would be a damp location and a standard 4 sq. is listed and rated as dry location only. Fitting shallow or fitting deep check listing.

The bases for the LED light fixture is connected to the junction box which contains the electrical leads that are prewired to the electrical components contained in the door sections. Determine exactly where the power is to be brought into the junction box.CoolBot Walk-in coolers use a Kason 1967-A3 light switch with a built-in thermometer. The Cooler Switch, thermometer and light fixture have been PRE-WIRED at the factory through the door frame.The wiring of a walk-in cooler involves various electrical components that work together to provide power and control the cooling system. These components include the main electrical panel, circuit breakers, power cables, control switches, temperature sensors, and lighting fixtures.All OUTLET BOXES and JUNCTION BOXES installed should be surface mount. On outdoor coolers, electrical installations should be done ONLY AFTER your outdoor membrane has been installed.

china cnc stainless manufacturer

walk in cooler drilling

preferred wiring method for walk in coolers

electric walk in cooler problems

Weisgram Metal Fab provides a complete spectrum of custom metalwork services to some of the world’s top brands. These services include metal fabrication, forming, welding, tool & die.

electrical j-box in walk-in coolers|electric walk in cooler problems