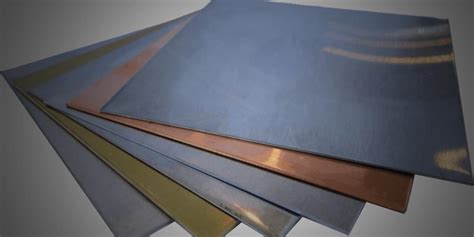

classification of sheet metal Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel. Sheet metal is available in flat pieces or . See more $15.65

0 · what is sheet metal

1 · types of sheet metal

2 · sheet steel grades

3 · sheet metal wikipedia

4 · sheet metal uses

5 · list of sheet metals

6 · grades of sheet metal

7 · grades of metal

Drill Size & Decimal Equivalents - Sheet Metal Gauges and Weights - Armstrong .

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel. Sheet metal is available in flat pieces or . See moreHand-hammered metal sheets have been used since ancient times for architectural purposes. Water-powered rolling mills replaced the manual process in the late 17th century. The . See moreBendingThe equation for estimating the maximum bending force is,$${\displaystyle F_{\text{max}}=k{\frac {TLt^{2}}{W}}}$$,where k is a factor taking into account several parameters . See moreFasteners that are commonly used on sheet metal include: clecos, rivets, and sheet metal screws. See more

• "Manufacturers Standard Gauge History". Steel Market Update. Archived from the original on 2013-09-28. Retrieved 2013-06-19.• "Sheet Steel Gauges and Thicknesses" (PDF). Sheet Steel Facts. Sachiya Steel International. . See more

Stainless steelGrade 304 is the most common of the three grades. It offers good corrosion resistance while . See moreThe use of sheet metal, through a comprehensive cold working process, including bending, shearing, punching, laser cutting, water jet cutting, riveting, splicing, etc. to make the final product we want (such as computer chassis, washing machine shells, . See more• Circle grid analysis• Corrugated galvanised iron, also known as Corrugated Sheet Metal• Diamond plate• Forming limit diagram See more In this resource, you’ll find steel classifications, usages, and types, along with our ASTM Steel Grade chart at the bottom. Let’s start by explaining the four main types of steel categories. Steel is a highly versatile material that can .

In the sheet metal production process, it is not enough to identify the steel number alone. As the steel used in production is supplied by the steel mills in accordance with certain .In this guide, we analyze the meanings behind steel, stainless steel and aluminum sheet metal grades. Steel is a mix of iron and carbon. Other alloys, along with the amount of carbon, determine a steel’s grade. Before we dive . Explore the various classifications of metal sheet materials, their properties, and industrial applications in this comprehensive guide for engineers and fabricators. In this article, we’ll discuss the four different types of steel, along with how they’re classified, the various steel grades and the methods of heat treatment used to improve steel’s .

cnc machine pdf file download

ASTM's steel standards are instrumental in classifying, evaluating, and specifying the material, chemical, mechanical, and metallurgical properties of the different types of steels, which are primarily used in the production of mechanical . There are over 3,500 different grades of steel. These grades are determined by analyzing the amount of carbon present and other alloying elements and production methods .In this comprehensive guide, we will explore the classifications, uses, and types of steel. Additionally, you’ll find our detailed ASTM Steel Grade chart at the bottom. Let’s begin by discussing the four primary categories of steel. Steel’s versatility .

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf , and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel . If you're in metal fabricating, you need to know metal grades. Our guide helps fabricators to understand sheet metal standards and what they are working with. In this resource, you’ll find steel classifications, usages, and types, along with our ASTM Steel Grade chart at the bottom. Let’s start by explaining the four main types of steel categories. Steel is a highly versatile material that can be used in various industries.

In the sheet metal production process, it is not enough to identify the steel number alone. As the steel used in production is supplied by the steel mills in accordance with certain size specifications, a reasonable choice of steel species and specifications must be made in order to improve product quality and steel utilisation to reduce production costs.

In this guide, we analyze the meanings behind steel, stainless steel and aluminum sheet metal grades. Steel is a mix of iron and carbon. Other alloys, along with the amount of carbon, determine a steel’s grade. Before we dive into steel grades, let’s break down the . Explore the various classifications of metal sheet materials, their properties, and industrial applications in this comprehensive guide for engineers and fabricators. In this article, we’ll discuss the four different types of steel, along with how they’re classified, the various steel grades and the methods of heat treatment used to improve steel’s mechanical properties. Steel is graded and classified into four groups: What are these many forms of steel made of, and what purpose do they serve? Let’s find out!ASTM's steel standards are instrumental in classifying, evaluating, and specifying the material, chemical, mechanical, and metallurgical properties of the different types of steels, which are primarily used in the production of mechanical components, industrial parts, and construction elements, as well as other accessories related to them.

There are over 3,500 different grades of steel. These grades are determined by analyzing the amount of carbon present and other alloying elements and production methods used. Steel grading systems allow us to categorize steel varieties based on their use case.In this comprehensive guide, we will explore the classifications, uses, and types of steel. Additionally, you’ll find our detailed ASTM Steel Grade chart at the bottom. Let’s begin by discussing the four primary categories of steel. Steel’s versatility allows it to be utilized across numerous industries.Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf , and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel .

what is sheet metal

types of sheet metal

If you're in metal fabricating, you need to know metal grades. Our guide helps fabricators to understand sheet metal standards and what they are working with. In this resource, you’ll find steel classifications, usages, and types, along with our ASTM Steel Grade chart at the bottom. Let’s start by explaining the four main types of steel categories. Steel is a highly versatile material that can be used in various industries. In the sheet metal production process, it is not enough to identify the steel number alone. As the steel used in production is supplied by the steel mills in accordance with certain size specifications, a reasonable choice of steel species and specifications must be made in order to improve product quality and steel utilisation to reduce production costs.

In this guide, we analyze the meanings behind steel, stainless steel and aluminum sheet metal grades. Steel is a mix of iron and carbon. Other alloys, along with the amount of carbon, determine a steel’s grade. Before we dive into steel grades, let’s break down the . Explore the various classifications of metal sheet materials, their properties, and industrial applications in this comprehensive guide for engineers and fabricators.

In this article, we’ll discuss the four different types of steel, along with how they’re classified, the various steel grades and the methods of heat treatment used to improve steel’s mechanical properties. Steel is graded and classified into four groups: What are these many forms of steel made of, and what purpose do they serve? Let’s find out!ASTM's steel standards are instrumental in classifying, evaluating, and specifying the material, chemical, mechanical, and metallurgical properties of the different types of steels, which are primarily used in the production of mechanical components, industrial parts, and construction elements, as well as other accessories related to them.

There are over 3,500 different grades of steel. These grades are determined by analyzing the amount of carbon present and other alloying elements and production methods used. Steel grading systems allow us to categorize steel varieties based on their use case.

cnc machine plasma factory

Discover precision and durability with our new sheet metal bending brakes at H. Weiss Machinery. From Baileigh Industrial to Roper Whitney and Tennsmith, choose from trusted brands for cost-effective solutions in sheet metal bending and forming.

classification of sheet metal|list of sheet metals