but welding sheet metal Learn why MIG, pulsed MIG, TIG and pulsed TIG are the ideal choices when welding sheet metal. When welding thin metal, the main objective is to avoid warping, burn . The 5v Crimp panel is an all-around quality system designed for both metal roofing and siding, and created for easy installation and a subtle visual appearance. Discover the classic appeal of 5V Crimp metal panels from Quality Metals.

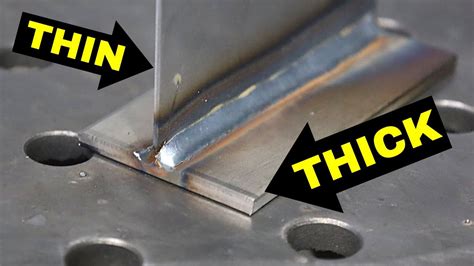

0 · welding thin to thick metal

1 · welding 14 gauge sheet metal

2 · welder settings for sheet metal

3 · welded sheet metal manufacturing

4 · sheet metal welding methods

5 · best welding for thin metal

6 · best welder for sheet metal

7 · 18 gauge weldable sheet metal

It can be used in the garage, shed or closet. This affordable bracket is made with a sturdy steel construction and has a durable gray finish. Bracket is sized to fit standard lumber widths. Each bracket has six holes for extra holding power. It is recommended that .

Learn why MIG, pulsed MIG, TIG and pulsed TIG are the ideal choices when welding sheet metal. When welding thin metal, the main objective is to avoid warping, burn . This guide explores the different methods of welding sheet metal in our shop and explains what to expect from each one. Today we will be going over some tricks to weld thin gauge sheet metal like body panels while avoiding wrapage. I go over 2 different techniques and several .

How to Weld Auto Body Sheet Metal With a TIG Welder. The best two electrodes for welding auto body sheet metal are either ceriated tungsten .Master the art of how to weld sheet metal with our comprehensive guide. Learn safety, techniques, best practices, and tips for welds. Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make. Learn why MIG, pulsed MIG, TIG and pulsed TIG are the ideal choices when welding sheet metal. When welding thin metal, the main objective is to avoid warping, burn-through and excessive heat-affected zones while still ensuring the weld has enough mechanical strength for the application.

This guide explores the different methods of welding sheet metal in our shop and explains what to expect from each one. Today we will be going over some tricks to weld thin gauge sheet metal like body panels while avoiding wrapage. I go over 2 different techniques and several . How to Weld Auto Body Sheet Metal With a TIG Welder. The best two electrodes for welding auto body sheet metal are either ceriated tungsten or thoriated tungsten.Master the art of how to weld sheet metal with our comprehensive guide. Learn safety, techniques, best practices, and tips for welds.

In this article, I am going to explain the fundamental ways of how to weld sheet metal that even professionals can follow. I have also put together a list of best welders for welding sheet metal so if you want to read it hop in. This article provides a detailed view of the various methods used in welding sheet metal, including their advantages and applications. It also provides vital tips to note when welding thin sheets of metal to obtain the best outcomes.

The following are the main welding processes used for Sheet Metal welding: Stick Welding or SMAW; Gas Tungsten Arc Welding (GTAW or TIG) Welding thin sheet metal can be challenging because you need to obtain adequate fusion while preventing distortion and burnthrough. The key skill is to control the heat across the sheet metal to prevent defects. This guide explains some of the ways to help get the best results when welding thin sheet metal. Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make.

Learn why MIG, pulsed MIG, TIG and pulsed TIG are the ideal choices when welding sheet metal. When welding thin metal, the main objective is to avoid warping, burn-through and excessive heat-affected zones while still ensuring the weld has enough mechanical strength for the application. This guide explores the different methods of welding sheet metal in our shop and explains what to expect from each one. Today we will be going over some tricks to weld thin gauge sheet metal like body panels while avoiding wrapage. I go over 2 different techniques and several .

How to Weld Auto Body Sheet Metal With a TIG Welder. The best two electrodes for welding auto body sheet metal are either ceriated tungsten or thoriated tungsten.

Master the art of how to weld sheet metal with our comprehensive guide. Learn safety, techniques, best practices, and tips for welds. In this article, I am going to explain the fundamental ways of how to weld sheet metal that even professionals can follow. I have also put together a list of best welders for welding sheet metal so if you want to read it hop in.

This article provides a detailed view of the various methods used in welding sheet metal, including their advantages and applications. It also provides vital tips to note when welding thin sheets of metal to obtain the best outcomes.

The following are the main welding processes used for Sheet Metal welding: Stick Welding or SMAW; Gas Tungsten Arc Welding (GTAW or TIG)

metal roller blind brackets b&

welding thin to thick metal

welding 14 gauge sheet metal

USS Gold Star metal boxCondition: It is in Used Condition showing some light normal use.Description: This is a very nice vintage WWII metal box noting the USS Gold Star. It will come exactly as shown..from

but welding sheet metal|18 gauge weldable sheet metal