composite metal sheets ALPOLIC ® /PE is an aluminum composite panel that is produced by laminating two . Power distribution boxes are the answer for powering tools in the midst of relief efforts. They are available in sizes ranging from 50 Amp to 400 Amp. Quality portable power devices should feature a vulcanized rubber enclosure and self-closing, waterproof lid.

0 · metal faced composite wall panels

1 · metal composite material MCM panels

2 · composite metal panel manufacturers

3 · aluminum composite panel sheet factory

4 · aluminum composite panel near me

5 · aluminum composite material sheet

6 · aluminum composite material near me

7 · 4mm aluminum composite panels

the metal stars you see on the outside of houses and barns — most commonly found in the more rural parts of the U.S. — actually have a deeper meaning. For one thing, those particular stars have a.

metal faced composite wall panels

ALPOLIC® is proud to be a global leader in metal composite manufacturing. Our commitment to quality, sustainability and customer care is unmatched. With a nearly unlimited selection of .ALPOLIC ® /PE is an aluminum composite panel that is produced by laminating two .

metal composite material MCM panels

Browse over 100 color samples of | ALPOLIC® finishes for metal composite .

Find a sales representative of ALPOLIC® metal composite materials near you. We .

ALPOLICⓇ materials are used in designs worldwide. Browse recent projects using .

ALPOLIC ® /RF provides a polished reflective aluminum surface suitable for .

ALUCOBOND PLUS is a high-quality, lightweight aluminum composite panel renowned for its durability, design flexibility, and exceptional performance in exterior cladding applications. 91 colors and finishes give shape to great ideas.These lightweight metal composite materials (MCM) provide superior flatness, durability and ease of maintenance in nearly limitless finishes that look as good as new for years after other .

Metal Composite Material (MCM) wall panels retain their luster for decades and is lightweight and installed faster than alternative exterior cladding, reducing structural steel requirements.

composite metal panel manufacturers

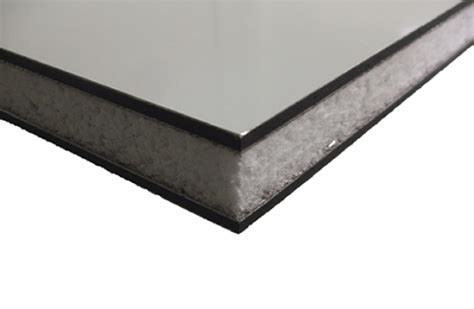

What Are MCM Panels? MCM panels are durable and low-maintenance cladding solutions. These metal composite materials are produced by sandwiching a lightweight thermoplastic core between two thin sheets of metal. MCM panels .Our premium aluminium composite material (ACM) is a metal cladding that's lightweight, durable, cost-effective, easy to fabricate and maintenance-free with an equally impressive range of .ALPOLIC ® /HD heavy duty panels are the strongest, most rigid aluminum composite materials we offer – providing superior tensile and yield strength with over five times the flexural .The BAMCO line of composite metal wall panel systems includes aluminum composite wall panels, architectural metal panels, and aluminum plate panels. Architectural Metal Wall Systems 1-800-245-0210

ALUCOBOND’s flatness, rigidity, lightweight and formability support a plethora of design intents. Our versatility of stocking colors & finishes gives designers the freedom to mix finishes without sacrificing budget. ALUCOBOND can .ALUCOBOND® is the original ACM (Aluminum Composite Material) MCM (Metal Composite Material). ALUCOBOND® brings a superior metal panel image to any project and is known for its lightweight qualities.ALPOLIC® is proud to be a global leader in metal composite manufacturing. Our commitment to quality, sustainability and customer care is unmatched. With a nearly unlimited selection of colors and finishes, premium ALPOLIC materials demand to be noticed in any setting.

Lightweight ACM panels with thinner aluminum skins designed for printed displays, architectural signs, canopies and other metal signage applications. Find The Look You Want. We offer an extensive selection of rich, vibrant colors and styles for .

Learn more about the ALPOLIC® Timber Series acm sheets. View architectural projects with the Timber series finish and Order samples for your next project!

ALPOLIC ® /HD heavy duty panels are the strongest, most rigid aluminum composite materials we offer – providing superior tensile and yield strength with over five times the flexural elasticity strength of our standard panels. These heavy duty panels incorporate skins of 0.032″ aluminum sheet metal – 60 percent thicker than our standard .ALPOLIC metal composite materials (MCM) are some of the most versatile architectural materials available. Offering the rigidity of heavy-gauge metals with the flexibility of a lightweight composite material, our MCM sheets include a polyethylene or fire-resistant core as a standard feature.ALPOLIC ® /fr sets the industry standard for fire safety while offering the same finish choices and ease of fabrication as our standard ALPOLIC ® /PE panels. Stock ALPOLIC ® /fr panels are 4mm thick and available in widths of 50″ and 62″ and lengths of 146″ and 196″.We bond metal skins to our polyethylene (PE) or fire-resistant (fr) core material to create a truly natural metal finish. The result is an MCM panel with all the beauty of sheet metal – and none of the drawbacks.

The ALPOLIC Zinc Elements Series offers our premium metal composite materials a timeless elegance and affordable luxury. Whether you prefer our natural QUARTZ-ZINC, the warm, earthy richness of the glazed-mineral pigments found in the PIGMENTO® line, or the dramatic, dark look of the ANTHRA finish, the Zinc Elements Series expands the depth of .ALPOLIC panels consist of a core of thermo-plastic material thermally bonded to face sheets fabricated of aluminum 3105 H14 alloy, 0.020" (0.5 mm) thick or an equivalent. TyPES Several types of ALPOLIC panels are avail-able, including: • ALPOLIC standard panels • ALPOLIC A-LOOKª reflective finish panels

Composite materials are more affordable, easier to install, and they offer superior flatness, durability, stability, vibration damping and ease of maintenance. Sheet metal tends to distort, or “oil can,” due to differential expansion and contraction in changing weather conditions.ALPOLIC® is proud to be a global leader in metal composite manufacturing. Our commitment to quality, sustainability and customer care is unmatched. With a nearly unlimited selection of colors and finishes, premium ALPOLIC materials demand to be noticed in any setting.Lightweight ACM panels with thinner aluminum skins designed for printed displays, architectural signs, canopies and other metal signage applications. Find The Look You Want. We offer an extensive selection of rich, vibrant colors and styles for .Learn more about the ALPOLIC® Timber Series acm sheets. View architectural projects with the Timber series finish and Order samples for your next project!

install surface mount electrical box

ALPOLIC ® /HD heavy duty panels are the strongest, most rigid aluminum composite materials we offer – providing superior tensile and yield strength with over five times the flexural elasticity strength of our standard panels. These heavy duty panels incorporate skins of 0.032″ aluminum sheet metal – 60 percent thicker than our standard .

ALPOLIC metal composite materials (MCM) are some of the most versatile architectural materials available. Offering the rigidity of heavy-gauge metals with the flexibility of a lightweight composite material, our MCM sheets include a polyethylene or fire-resistant core as a standard feature.ALPOLIC ® /fr sets the industry standard for fire safety while offering the same finish choices and ease of fabrication as our standard ALPOLIC ® /PE panels. Stock ALPOLIC ® /fr panels are 4mm thick and available in widths of 50″ and 62″ and lengths of 146″ and 196″.

We bond metal skins to our polyethylene (PE) or fire-resistant (fr) core material to create a truly natural metal finish. The result is an MCM panel with all the beauty of sheet metal – and none of the drawbacks.

aluminum composite panel sheet factory

The ALPOLIC Zinc Elements Series offers our premium metal composite materials a timeless elegance and affordable luxury. Whether you prefer our natural QUARTZ-ZINC, the warm, earthy richness of the glazed-mineral pigments found in the PIGMENTO® line, or the dramatic, dark look of the ANTHRA finish, the Zinc Elements Series expands the depth of .ALPOLIC panels consist of a core of thermo-plastic material thermally bonded to face sheets fabricated of aluminum 3105 H14 alloy, 0.020" (0.5 mm) thick or an equivalent. TyPES Several types of ALPOLIC panels are avail-able, including: • ALPOLIC standard panels • ALPOLIC A-LOOKª reflective finish panels

aluminum composite panel near me

aluminum composite material sheet

There's a heavy (and clearly obvious) emphasis on using plastic/metal electrical boxes when working with switches, receptacles, lights, etc. However, when installing an outdoor light fixture, I'm finding just the opposite.

composite metal sheets|aluminum composite material sheet