types of sheet metal joints There are five common types of sheet metal joints that are extremely common across the industry, all with varying uses and advantages. What is 4-axis CNC Machining? 4-axis CNC machining is a type of advanced machining that uses CNC machines with an extra rotating axis. This rotation lets you work on four sides of a part while it remains clamped in one position, .

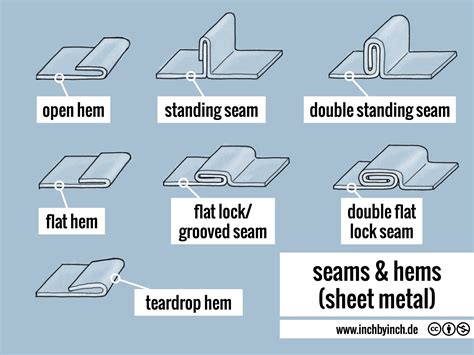

0 · types of sheet metal seams

1 · sheet metal overlap joint

2 · sheet metal joints pdf

3 · sheet metal joints and seams

4 · sheet metal clinching joint

5 · interlocking sheet metal joints

6 · different types of metal joints

7 · different joining methods for metal

A junction box – also known as an ‘electrical box’, ‘jbox’, ‘or ‘terminal box’ – is a protective box where wires are interconnected. Junction boxes are often built into the plaster of a wall, in the ceiling, or within concrete.

Joint reliability depends on its type, sheet metal material, and manufacturing process. This article covers various types of sheet metal joining techniques, their advantages, disadvantages, and applications.

describe the several types of metallic and nonmetallic boxes

Self tapping screws, wooden screws, sheet metal screws, Machine screws, Security .Sheet metal material selection is an iterative process. After the material selection, it .There are five common types of sheet metal joints that are extremely common across the industry, all with varying uses and advantages.

types of sheet metal seams

There are five major welding joint types: butt joint, tee joint, corner joint, lap joint and edge joint. Butt joints are the most common and can be made in various ways depending on factors like groove shape and width.There are a range of different welding techniques that can be used to join sheet metals, such as MIG and TIG welding, laser welding or friction stir welding, which is good for quickly joining sheets that are long or wide.

A butt joint is one of the most common and straightforward types of welding joints. It involves two metal plates placed edge to edge in the same plane and welded along the seam. This joint type is widely used across . Discover how these joints impact the strength and durability of metal structures. Shane. August 15th, 2024. Welding. Table Of Contents. I. Weld Joints and Weld Seams. Arc welding joints are complex structures composed . Here are some common types of welding joints: Butt Joint Weld. A butt joint refers to aligning the edges of two steel plates opposite each other and joining them tightly through welding processes to form a straight line on their . 5 Common Types of Welding Joints. Welding joints are classified based on how the pieces of metal are joined together. There are a wide variety of types of welded joints, each carefully selected for specific application needs, .

sheet metal overlap joint

sheet metal joints pdf

Sheet metal joints are found in every sheet metal assembly. Sheet metal fabrication techniques create these special joints to enable the proper function of t.

These types of joints are among some of the most common in the sheet metal industry, such as in the construction of frames, boxes and other applications. There are two ways of fitting up an outside corner joint—either it .

These types of welding joints form when the two metal pieces are placed end to end together in the same plane surface, it is known as butt joint welding. In welding, this is the most common type of joint. Usually, butt joint welding is used for the fabrication of structures, welding pipes, valves, fittings, and others.

The two main types of sheet metal screws are self-tapping screws and self-drilling screws, each possessing unique advantages and characteristics when it comes to fastening sheet metal components. . Types of Welding Joints: The 5 Basic Types and Their Variations. Sheet Metal Fabrication Guide | June 24, 2024 . About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright . Depending on your project requirements, wood screws have two common types of heads – countersink head and pan head. Countersink head screws are used for countersunk holes, while Pan head screws are used for non-countersunk holes. Sheet Metal Screws. Sheet metal screws are designed for joining sheet metals, and they work by drilling into the . How can we ensure secure and durable connections in sheet metal fabrication? This article explores various joining and fastening techniques, including TOX riveting, welding, and nail riveting. . (produced in Taiwan), can weld plate thickness range of 0.2-3mm for lap joint of two plates. Capacitor storage type spot welding machine:

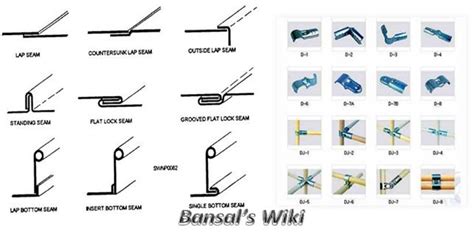

According to the requirements many different types of joints are used in sheet metal work. A lap joint is very frequently used and can be prepared by means of soldering or riveting. Seam joint is a very commonly used one. It is locked so as to ensure a positive grip and also to make the joint flush with the surface.A butt joint is a common type of joint used in the fabrication of structures and piping systems, where two pieces of metal are placed together in the same plane, and the side of each metal is joined by welding. . Corner joints, similar to tee welding joints, are common in the sheet metal industry, particularly in the construction of frames .

However, there are other types of welding joints. Lap Joint. Lap joints are a typical modification of butt joints. They are the go-to joints to weld sheet metal with varying thicknesses. In the lap joint, the two pieces of metals join in an overlap – one placed over the other. The major shortcoming of the lap joint is that the junction of the .There are five types of welding joints: corner, butt, lap, tee, and edge. Each type has a specific purpose and ensures solid and durable structures. . they create a corner joint. Sheet metal workers, framers, and box constructors commonly use this type of joint to form an external corner. Corner Joint: Pros & Cons. Pros:

These types of joints are among the most common in the sheet metal industry, found in the construction of frames, boxes, and other applications. There are two ways of fitting up an outside corner joint—either forming a V-groove (A) or forming a square butt joint (B), as seen in the diagram below.Sheet metal is sometimes arranged with joints, according to Scribd. The types of joints include the flush joint, which must have one sheet that is level, the edge over joint, which is used when fixing the bottoms of objects, grooved joints, where one edge is folded down and one is folded up and double grooved joints. . #sheet metal #sheet #sheet metal operations #types of sheet metal joints This video is about sheet metal joints and types.hem and types, seam and types.इस वी.

Selecting the appropriate weld joint type for a sheet metal project is essential for achieving the best results in terms of strength, durability, and efficiency. To make the right choice, it is important to consider factors such as .

sheet metal joints and seams

Sheet Metal // Ham // Seam // Notch // Grooved Seam // Lap Joint // 💥 #Operation_of_Sheet_MetalITI TECHNICAL ZONE प्रिय . Flange - Create a wall for each edge selected, connected to the selected edge with a bend.; Tab - Add a tab to a sheet metal flange.; Make joint - Convert the intersection of two walls into a joint feature, either a bend (walls joined by cylindrical geometry) or a rip (small gap between two walls).; Corner - Modify a corner type and relief scale.; Bend relief - Modify a .5 Grooved Seam Joint The Grooved Seam Joint is a SELF- SECURED JOINT Once finally formed (using the correct sized grooving tool) the joint should not come apart! If the joint needs to be gas or water tight then it will be necessary to solder or use a non thermal bonding method (please note this not required to hold the joint together).There are 5 basic joint types used in the metal fabrication field: . Corner Joint: being one of the most popular welds in the sheet metal industry the corner joint is used on the outer edge of the piece. This weld is a type of joint that comes together at right angles between two metal parts to form an L. These are common in the construction .

The joining process data collection was carried out from two approaches: quantitative (joining sheet thickness, joint dimensions, production batch and joining strength) and qualitative (type of .

The joints can be finished by soldering and/or riveting. When developing sheet-metal patterns, ensure you add sufficient material to the base dimensions to make the seams. Several types of seams used to join sheet-metal sections are discussed in this section.3. Corner Joint Welding. The sheet metal sector loves this type of joint. It is used when welding on the outside of the adjoining metal pieces. If you have placed the pieces correctly (at right angles), the finished item will create an L shape.Sheet metal fits all “green” building materials measures, especially recycled content – Recycled content: steel = 25%; roofing copper = >75%; – Energy efficiency per Florida Solar Research = light-colored metal roofs VERY energy efficient Soldered sheet metal joints are “sustainable” and do not require continuous maintenance—unlike

Lap joints are ideal in applications like sheet metal work and fabrication. They provide excellent strength and resistance to shear forces, making them reliable for various structural purposes. Welding Techniques and Their Influence on Joint Types. Welding techniques significantly influence the types of joints formed in metal fabrication.Chapter 4 Very few stand-alone sheet metal components are used as a final product by themselves. Usually, a final product appears after joining one or more parts in a sheet metal product assembly. They may be fixed permanently or temporarily. A good amount of detailing goes before the realization of a final product. A flawless mating of two parts begins at a .type of joint includes the application of an appropriate sealant at each joint. Figure 15-1 The Basic Lap Joint . A variation of the lap joint is the . nested. lap, which is utilized by many types of ribbed metal panels. A nested lap joint overlaps the adjacent panel, but also covers or "nests" the lower panel rib within the rib of the lapping .

sheet metal clinching joint

Old work electrical boxes are used when you need to add an electrical box to walls that are closed in or covered with drywall. These boxes are designed to.

types of sheet metal joints|sheet metal joints pdf