history of cnc machine wikipedia Motion is controlling multiple axes, normally at least two (X and Y), and a tool spindle that moves in the Z (depth). The position of the tool is driven by direct-drive stepper motors or servo motors to provide highly accurate movements, or in older designs, motors . See more Vance Metal has completed the Certification process for the ASME U and R Pressure .

0 · who invented cnc machine

1 · when were cnc machines invented

2 · when did cnc machining start

3 · history of cnc machine pdf

4 · evolution of cnc machines

5 · cnc timeline

6 · cnc machine history timeline

7 · cnc machine background

$20.00

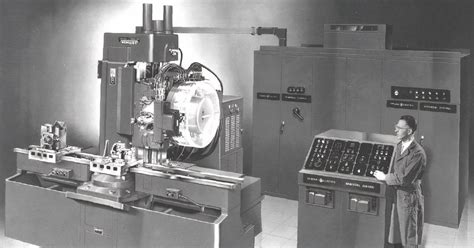

The first CNC machines were built in the 1940s and 1950s, based on existing tools that were modified with motors that moved the tool or part to follow points fed into the system on punched tape. These early servomechanisms were rapidly augmented with analog and digital computers, creating the modern CNC . See moreIn machining, numerical control, also called computer numerical control (CNC), is the automated control of tools by means of a computer. It is used to operate tools such as drills, lathes, mills, grinders, routers and 3D printers. . See more

Motion is controlling multiple axes, normally at least two (X and Y), and a tool spindle that moves in the Z (depth). The position of the tool is driven by direct-drive stepper motors or servo motors to provide highly accurate movements, or in older designs, motors . See moreMany other tools have CNC variants, including:• 3D printing• See moreWithin the numerical systems of CNC programming, the code generator can assume that the controlled mechanism is always perfectly . See more

Now the CNC in the processing manufacturing field has been very extensive, not only the traditional milling and turning, other machines and equipment are also installed with the corresponding CNC, which makes the manufacturing . See moreIn CNC, a "crash" occurs when the machine moves in such a way that is harmful to the machine, tools, or parts being machined, . See moreIn numerical control systems, the position of the tool is defined by a set of instructions called the part program. Positioning control is handled using either an open-loop or a closed-loop system. In an open-loop system, communication takes place in one . See more

The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the ongoing evolution of computer numerical control (CNC) technology. The first NC machines were built in the 1940s and 1950s, based on existing tools that were modified with motors that moved the controls to follow points fed into the system on punched tape. .A computer numerical control (CNC) router is a computer-controlled cutting machine which typically mounts a hand-held router as a spindle which is used for cutting various materials, .The history of CNC (Computer Numerical Control) technology dates back to the mid-20th century. In the late 1940s and early 1950s, researchers and engineers began exploring ways to .

John T. Parsons is often credited as the man who invented the CNC machine and hailed as the father of CNC machining. He introduced the world to the concept of numerical control for machine tools in the 1940s.

who invented cnc machine

Historical Beginnings. The story of CNC machining dates back to the 1940s and 1950s, originating from the need for high-precision machining for the defense and aerospace industries during . In "History of CNC Machining, Part 1," we look at predecessor mechanisms that laid the foundation and the series of events that led to the birth of numerical control. The initial prototype used eight-column paper tape, a tape reader, and a vacuum-tube electronic control system, setting the stage for future advancements. During the 1940s and 1950s, early CNC machines utilized . In this article, we’ll take a look at the history of CNC machines, and how they got to where they are today. Early Days: Numerical Control (NC) Like so many innovations, the history of CNC technology has its origins in military .

The invention of CNC machinery revolutionized the manufacturing industry, enabling the automated production of complex parts with unprecedented speed, accuracy, and efficiency. John T. Parsons' pioneering work laid the .Okuma Corporation (オークマ株式会社, Ōkuma Kabushiki-gaisha) is a machine tool builder based in Ōguchi, Aichi Prefecture, Japan.It has global market share in CNC machine tools such as CNC lathes, machining centers, and turn-mill machining centers.The company also offers FA (factory automation) products and servomotors. [2]It is listed on the Tokyo Stock Exchange and is a .

A Janvier Reducing Machine. A Reducing Machine was a type of pantograph lathe used until the 21st century to manufacture coin dies.Prior to the machine's introduction, designs were cut by hand into metal dies by a specialist engraver.The reducing machine changed this by allowing artists to create designs on a larger surface area and then have them scaled down and cut into .

The History of CNC Article Source/Subject: Wikipedia - (CNC) Computer Numerical Control Article Contents: History - Earlier forms of automation - Cams - Tracer control - Servos and selsyns - Parsons and the invention of NC - Enter MIT - MIT's machine - Proliferation of NC - CNC arrives - CAD meets CNC - Proliferation of CNC - Today - Description - Tools with CNC variants - . The Developing History of CNC Machines Early Developments (1940s-1950s): The concept of Numerical Control (NC) took shape in 1949 when John T. Parsons, an early computing pioneer, developed it during an Air Force research project at MIT. The project aimed to create motorized axes for manufacturing helicopter blades and aircraft skins. CNC machines have a program controlling the movement of tools that determines the machining function on the block to be machined. During turning, it defines the axis of rotation and the milling cutter rotation axis. A milling machine with around three or five axes is controlled by a computer and is totally automated. The milling cutter route is .LMW Limited is India's largest textile machinery and CNC machine tool manufacturers, based in Coimbatore and founded by Dr. G.K. Devarajulu. It started its operation in 1962 in Periyanaickenpalayam in Coimbatore city with technical collaboration with Swiss-based textile machinery manufacturer Rieter for textile machines and German based steel and ammunition .

The term "automatic lathe" is still often used in manufacturing in its earlier sense, referring to automated lathes of non-CNC types.The first automatic lathes were mechanically automated and controlled by cams or tracers and pantographs.Thus, before electronic automation via numerical control, the "automatic" in the term "automatic machine tool" always referred implicitly to .Multiaxis CNC machines are used in many industries including: Aerospace industry: Multiaxis machines are used in the manufacturing of aircraft parts, which allow for complex parts to be made efficiently. [6]Automotive industry: Multiaxis CNC machines create engine housings, rims and headlights. [7]Furniture industry: CNC lathes mass-produce wooden table legs as well as .ANCA Pty Ltd (formerly Australian Numerical Control and Automation Pty Ltd) is an Australian company which designs and manufactures computer numerical controlled grinding machines.The company was founded in 1974 by Pat Boland and Pat McCluskey in Melbourne, Australia.. ANCA has its headquarters and main manufacturing plant in Melbourne where it employs about 400 . A CNC machine is a system combining multiple tools (including drills, lathes, and milling tools), which are built into cells from which the machine can select and use them. It is designed to manufacture three-dimensional parts. The simplest machines move in one or two axes. On the other hand, more advanced systems feature X- and Y-axis motion .

CNC plasma cutting Plasma cutting performed by an industrial robot. Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma.Typical materials cut with a plasma torch include steel, stainless steel, aluminum, brass and copper, although other conductive metals may be cut as well.Plasma cutting is often used .[13] [14] As CAM software and machines become more complicated, the skills required of a machinist or machine operator advance to approach that of a computer programmer and engineer rather than eliminating the CNC machinist from the workforce. Typical areas of concern. High-Speed Machining, including streamlining of tool paths; Multi-function .

Ghost Gunner began as a limited series of CNC mills produced by Defense Distributed in a crowdfunding sale to its mailing list in October 2014. Spring 2015 shipments sold out almost immediately, and its first media reviewer noted the machine ".worked so well that it may signal a new era in the gun control debate, one where the barrier to legally building an untraceable, .The journey of CNC (Computer Numerical Control) machining from its inception to the present day is a testament to the leaps and bounds by which technology has transformed manufacturing. CNC machining stands as a pillar of modern production, offering unparalleled precision, efficiency, and versatility. This article traces the evolution of CNC machining, exploring its historical [.]A metal lathe is an example of a machine tool.. A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations.Machine tools employ some .Mori Seiki was founded in 1948 by the three Mori brothers. [8] [3] It originally produced textile machinery, but in 1958, the company entered the machine tool manufacturing industry, and by 1968, it began manufacturing numerical control (NC) lathes.[9]In 2001, grinding machine manufacturer Taiyo Koki joined the DMG Mori Group [10] and in 2002, DMG Mori Co., Ltd. .

Commercial machine embroidery in chain stitch on a voile curtain, China, early 21st century. Machine embroidery is an embroidery process whereby a sewing machine or embroidery machine is used to create patterns on textiles. It is used commercially in product branding, corporate advertising, and uniform adornment. It is also used in the fashion industry to decorate .This page was last edited on 19 February 2009, at 14:00 (UTC).; Text is available under the

Headquarters and factories FANUC PLC. FANUC (/ ˈ f æ n ə k / or / ˈ f æ n ʊ k /; often styled Fanuc) is a Japanese group of companies that provide automation products and services such as robotics and computer numerical control wireless systems. [6] These companies are principally FANUC Corporation (ファナック株式会社, Fanakku Kabushikigaisha) of Japan, Fanuc .A typical milling machine of the era, built by Cincinnati Milling Machine Company. It is a horizontal, with an overarm for the arbor. The Cincinnati Milling Machine Company was an American machine tool builder headquartered in Cincinnati, Ohio.Incorporated in 1889, the company was formed for the purpose of building and promoting innovative new machine tool designs, .Murata Machinery, Ltd. (村田機械株式会社, Murata Kikai Kabushiki-gaisha), abbrev.MML, is a privately held Japanese international company founded in 1935 with its head office at Fushimi-ku, Kyoto. The company's main products are industrial machines such as textile machinery, turning machines, sheet metal machinery and communication equipment like digital multifunctional .The company was founded in 1919 in Nagoya by Sadakichi Yamazaki as a small company making pots and pans. [4] During the 1920s it progressed through mat-making machinery to woodworking machinery to metalworking machine tools, especially lathes. [5] The company was part of Japan's industrial buildup before and during World War II, then, like the rest of Japanese industry, was .

In this blog post, we will delve into the history of CNC machines, exploring their origins, technological developments, and their impact on modern-day manufacturing processes. Origins of CNC Machines: The foundation of CNC machines can be traced back to the 1940s and 1950s when the first computer-controlled machines were developed.CNC machine pouring coolant to keep the tool and parts from getting hot Lathe machine. Machining is a manufacturing process where a desired shape or part is created using the controlled removal of material, most often metal, from a larger piece of raw material by cutting. Machining is a form of subtractive manufacturing, [1] which utilizes machine tools, in contrast .

This document provides an overview of CNC (computer numerical control) machines. It discusses the history and evolution of CNC machines from the 1940s to present day. The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit.Diagram of a laser cutter Laser cutting process on a sheet of steel CAD (top) and stainless steel laser-cut part (bottom). Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. While typically used for industrial manufacturing applications, it is now used by schools, small businesses, architecture, and hobbyists.

when were cnc machines invented

VariTrane® variable-air-volume (VAV) units lead the industry in quality and reliability and are designed to meet the specific needs of today’s applications. Help to control comfort, indoor air quality (IAQ), noise levels, and energy .

history of cnc machine wikipedia|when were cnc machines invented