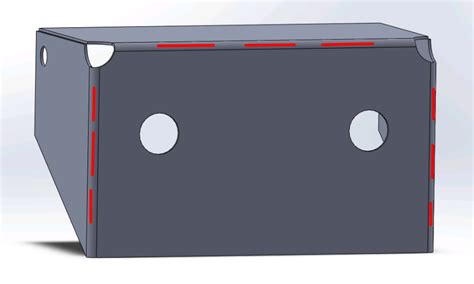

bending relief for sheet metal Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Recommended Bend Relief height is always more than two times of . Best Metal Fabricators in Cincinnati Metropolitan Area - Marx Fabrication, Valley Metal Works, Morehouse Welding, Elsmere Ironworks, Sandmann Welding & Fabrication, Bluegrass Iron Works, Industrial Tube & Steel, Metal Solutions Design & .

0 · solidworks sheet metal relief cut

1 · solidworks sheet metal corner relief

2 · solidworks sheet metal bend relief

3 · sheet metal fabrication design guide

4 · sheet metal corner relief chart

5 · sheet metal bending chart

6 · sheet metal bend relief guidelines

7 · auto relief solidworks sheet metal

Service Metal Works is a Chicago sheet metal fabricator specializing in welded assemblies as well as tubing fabrication and wire fabrication. We will make and ship to you either individual parts .

A bend relief prevents tears from occurring where there is a transition between bends or between a bend and a flat surface. They are a .

stainless steel box tubing

The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements and how they differ depending on . Learn the crucial sheet metal bend relief rules for smooth fabrication and Essential sheet metal bend relief guidelines. Expert tips for your successful projects.Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Recommended Bend Relief height is always more than two times of .

solidworks sheet metal relief cut

See how and when specifically to design bend reliefs and corner reliefs in sheet metal parts to open up geometry options & tighter tolerances A bend relief prevents tears from occurring where there is a transition between bends or between a bend and a flat surface. They are a great way to ensure a clean looking part that is free from deformation, burrs, and sharp points where the bend edges terminate.

The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements and how they differ depending on whether you are coining or air bending on a press brake, and adding bend relief to prevent tearing material. Learn the crucial sheet metal bend relief rules for smooth fabrication and Essential sheet metal bend relief guidelines. Expert tips for your successful projects.Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Recommended Bend Relief height is always more than two times of sheet thickness plus bend radius. Creating an extruded hole . Bend reliefs prevent tears during transitions between bends or between a bend and a flat surface. They ensure a clean part free from deformation, burrs, and sharp points, especially crucial for parts subject to vibration or flexion.

solidworks sheet metal corner relief

solidworks sheet metal bend relief

Bend reliefs are two small cuts made in a piece of sheet metal to free up the metal between them. Although they are small features, leaving them out can cause stress to concentrate at the bend line, resulting in deformed holes and slots.

CUT/BEND RELIEF DESIGN TIPS • To ensure cost-effective production, design cut and bend reliefs with a minimum of 2.5x material thickness. • For prototype and short-run quantities, the minimum cut relief can be a laser or water jet cut kerf (0.010” - 0.040”). • Lanced (sheared) features with zero cut relief are possible but

Bend relief, also known as bend allowance or bend deduction, is a design technique used to mitigate the effects of stress and deformation that occur during the bending process. When a metal sheet is bent, the inner radius compresses while the outer radius stretches.

A bend relief creates space between the bent and unbent surfaces so that the edge of the sheet metal is perpendicular to the bend itself. The gap between the bend and surrounding material allows us to shape the sheet in the press brake cleanly, eliminating cracking and tearing. See how and when specifically to design bend reliefs and corner reliefs in sheet metal parts to open up geometry options & tighter tolerances A bend relief prevents tears from occurring where there is a transition between bends or between a bend and a flat surface. They are a great way to ensure a clean looking part that is free from deformation, burrs, and sharp points where the bend edges terminate. The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements and how they differ depending on whether you are coining or air bending on a press brake, and adding bend relief to prevent tearing material.

Learn the crucial sheet metal bend relief rules for smooth fabrication and Essential sheet metal bend relief guidelines. Expert tips for your successful projects.Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Recommended Bend Relief height is always more than two times of sheet thickness plus bend radius. Creating an extruded hole .

Bend reliefs prevent tears during transitions between bends or between a bend and a flat surface. They ensure a clean part free from deformation, burrs, and sharp points, especially crucial for parts subject to vibration or flexion.Bend reliefs are two small cuts made in a piece of sheet metal to free up the metal between them. Although they are small features, leaving them out can cause stress to concentrate at the bend line, resulting in deformed holes and slots.

CUT/BEND RELIEF DESIGN TIPS • To ensure cost-effective production, design cut and bend reliefs with a minimum of 2.5x material thickness. • For prototype and short-run quantities, the minimum cut relief can be a laser or water jet cut kerf (0.010” - 0.040”). • Lanced (sheared) features with zero cut relief are possible butBend relief, also known as bend allowance or bend deduction, is a design technique used to mitigate the effects of stress and deformation that occur during the bending process. When a metal sheet is bent, the inner radius compresses while the outer radius stretches.

sheet metal fabrication design guide

sheet metal corner relief chart

double yellow kerb markings (except where parking spaces have been provided, where entrance to or exit from the road is made, where there is a prohibition or restriction on

bending relief for sheet metal|sheet metal fabrication design guide