efficient sheet metal fabrication The following sheet metal design tips should serve as a guide towards ensuring the efficient design of sheet metal parts. These tips have been developed based on standard DfM practices, changing industrial requirements, and analysis of metal fabricated products.

In CNC lathe machines, the headstock is upgraded by installing a bar feeder for AUTOMATIC feed functions and continuous lathe machine operations. This all-metal structure provides strength to the machine tool , enabling it to resist strong vibrations during a machining operation.

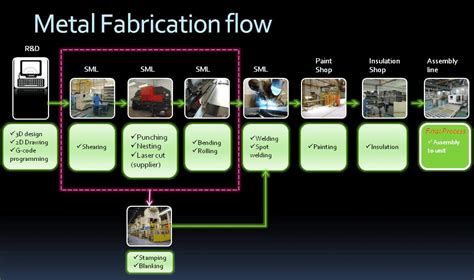

0 · sheet metal shearing process

1 · sheet metal manufacturing shops

2 · sheet metal manufacturing process

3 · sheet metal fabrication shop practices

4 · sheet metal fabrication process

5 · sheet metal fabrication best practices

6 · how to improve sheet metal fabrication

There are a few specific types of metal that are magnetic. Common examples include nickel, cobalt, iron, dysprosium, and neodymium. There are some projects that are completed with certain percentages of different types of metal. Furthermore, there are some alloys that are made up of two or more materials.

Benefits of Lean in Sheet Metal Fabrication. Applying lean principles to sheet metal fabrication provides several vital advantages: Efficiency Gains: Lean methods eliminate redundancies, streamline workflows, reduce lead times, and establish a more agile manufacturing process. . 7 Sheet Metal Fabrication Best Practices to stay competitive and improve profitability. Running a sheet metal fabrication shop requires careful planning, efficient operations, and a focus on quality. Here is a list of best .Benefits of Lean in Sheet Metal Fabrication. Applying lean principles to sheet metal fabrication provides several vital advantages: Efficiency Gains: Lean methods eliminate redundancies, streamline workflows, reduce lead times, and establish a more agile manufacturing process. For example, minimizing waiting periods between steps accelerates . 7 Sheet Metal Fabrication Best Practices to stay competitive and improve profitability. Running a sheet metal fabrication shop requires careful planning, efficient operations, and a focus on quality. Here is a list of best practices to consider:

Understanding the various fabrication techniques is crucial for effective decision-making, cost optimization, and quality control. In this guide, we’ll explore the key sheet metal fabrication techniques, their advantages, and their applications. The following sheet metal design tips should serve as a guide towards ensuring the efficient design of sheet metal parts. These tips have been developed based on standard DfM practices, changing industrial requirements, and analysis of metal fabricated products. This is an overview of how to optimise sheet metal fabrication for cost reduction in design and production. It covers critical aspects such as material selection, cutting methods, bending techniques, welding, assembly, and prototyping. Master the art of sheet metal fabrication with our comprehensive handbook. Learn about the latest technology and techniques for cutting, bending, and finishing sheet metal projects with precision and efficiency.

Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting. How does sheet metal fabrication work? Explore custom sheet metal fabrication. Discover techniques, essential tools, and finishing processes like powder coating and anodizing. Prioritize material selection and geometric considerations for efficient sheet metal fabrication. Embrace DFM principles to minimize costs and enhance product quality in manufacturing. Implement design guidelines and tolerance specifications tailored for .

Mastering sheet metal design is key to achieving both precision and efficiency in manufacturing sheet metal parts. By incorporating Design for Manufacturing (DFM) principles, you can streamline production, reduce costs, and maintain high-quality standards.Benefits of Lean in Sheet Metal Fabrication. Applying lean principles to sheet metal fabrication provides several vital advantages: Efficiency Gains: Lean methods eliminate redundancies, streamline workflows, reduce lead times, and establish a more agile manufacturing process. For example, minimizing waiting periods between steps accelerates . 7 Sheet Metal Fabrication Best Practices to stay competitive and improve profitability. Running a sheet metal fabrication shop requires careful planning, efficient operations, and a focus on quality. Here is a list of best practices to consider:

Understanding the various fabrication techniques is crucial for effective decision-making, cost optimization, and quality control. In this guide, we’ll explore the key sheet metal fabrication techniques, their advantages, and their applications. The following sheet metal design tips should serve as a guide towards ensuring the efficient design of sheet metal parts. These tips have been developed based on standard DfM practices, changing industrial requirements, and analysis of metal fabricated products. This is an overview of how to optimise sheet metal fabrication for cost reduction in design and production. It covers critical aspects such as material selection, cutting methods, bending techniques, welding, assembly, and prototyping. Master the art of sheet metal fabrication with our comprehensive handbook. Learn about the latest technology and techniques for cutting, bending, and finishing sheet metal projects with precision and efficiency.

sheet metal shearing process

Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting. How does sheet metal fabrication work? Explore custom sheet metal fabrication. Discover techniques, essential tools, and finishing processes like powder coating and anodizing. Prioritize material selection and geometric considerations for efficient sheet metal fabrication. Embrace DFM principles to minimize costs and enhance product quality in manufacturing. Implement design guidelines and tolerance specifications tailored for .

security lock box steel

sheet metal manufacturing shops

When purchasing a box to use as a junction box, determine the correct size based on fill capacity restrictions: Separate the circuit wires at the existing splice and loosen the cables as needed to make room for the new junction box.

efficient sheet metal fabrication|sheet metal fabrication shop practices