blanking process in sheet metal pdf Blanking and piercing are manufacturing processes by which certain geometrical shapes are sheared off a sheet metal. If the sheared off part is the one required, the processes referred to as. I'm tempted to 3d print an enclosure for it or see if I could find a large enough outdoor electrical box that could mount a GFI outlet plus the Eth over PL unit. I am looking for a Powerline .

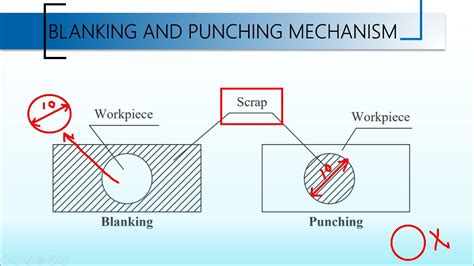

0 · punching and blanking diagram

1 · perforating operation in sheet metal

2 · differentiate between blanking and punching

3 · difference between shearing and blanking

4 · difference between blanking and punching

5 · difference between blanking and piercing

6 · difference between blanking and fine

7 · blanking and piercing diagram

Designed to withstand the elements, this large junction box provides ample space for secure cable connections. The grey exterior blends seamlessly with outdoor surroundings, while the sturdy construction protects electrical connections from moisture, dust, and debris.

punching and blanking diagram

Blanking is a widely used process in sheet metal components. It is a cutting operation in which material is cut in between punch and dies interface. In this process a piece of sheet metal is .Abstract- Metal blanking is a widely used process in high volume production of .

Blanking and piercing are manufacturing processes by which certain geometrical shapes are sheared off a sheet metal. If the sheared off part is the one required, the processes referred to as.

do you need electric box for outdoor light

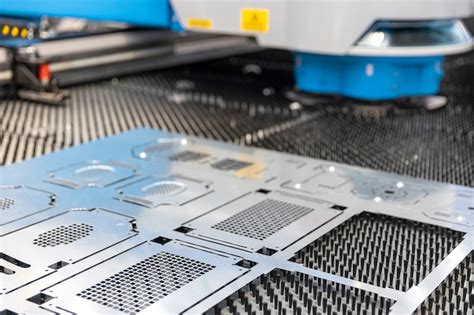

The sheet metal blanking process consists in separating a blank from a sheet by a punch. It combines material plastic flow and ductile fracture. The main characteristics associated with .Abstract: This document prescribes a model investigation the effect of potential parameters influencing the blanking process and their interaction.Sheet metal is metal formed by an industrial process into thin, flat pieces. It is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of shapes. .Abstract- Metal blanking is a widely used process in high volume production of sheet metal components. Blanking consists of a metal forming operation characterized by complete .

PDF | The steel sheet metal blanking is widely used for the manufacture of mechanical parts for automotive industry. The general concept of blanking. | Find, read and cite all the.This document discusses the design of sheet metal blanking and piercing tools. It begins by introducing sheet metal working as a chip-less manufacturing process to make components from sheet metal less than 20mm thick using presses.

Blanking is a widely used process in sheet metal components. It is a cutting operation in which material is cut in between punch and dies interface. In this process a piece of sheet metal is removed from a larger piece of stock by applying a enough shearing force. The piece removed, called the blank, is not scrap but rather the desired part. Blanking and piercing are manufacturing processes by which certain geometrical shapes are sheared off a sheet metal. If the sheared off part is the one required, the processes referred to as.

Piercing and Blanking • Piercing and blanking are shearing operations where a part is removed from sheet material by forcing a shaped punch through the sheet and into a shaped die • Blanking- the piece being punched out becomes the workpiece • Piercing- the punchout is the scrap and the remaining strip is the workpiece In this article, you will learn the 9 different types of sheet metal operations with diagrams. Also, you can download the pdf file of this post. What is the Sheet Metal Process? The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication.The sheet metal blanking process consists in separating a blank from a sheet by a punch. It combines material plastic flow and ductile fracture. The main characteristics associated with the blanking operation are the global behavior related to the punch force versus the punch displacement curve and the cut edge shape (burr size).Abstract: This document prescribes a model investigation the effect of potential parameters influencing the blanking process and their interaction.

Sheet metal is metal formed by an industrial process into thin, flat pieces. It is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of shapes. Countless everyday objects are constructed with sheet metal. Thicknesses canAbstract- Metal blanking is a widely used process in high volume production of sheet metal components. Blanking consists of a metal forming operation characterized by complete material separation. Low carbon steel is a very common material used in .

PDF | The steel sheet metal blanking is widely used for the manufacture of mechanical parts for automotive industry. The general concept of blanking. | Find, read and cite all the.

This document discusses the design of sheet metal blanking and piercing tools. It begins by introducing sheet metal working as a chip-less manufacturing process to make components from sheet metal less than 20mm thick using presses.

Blanking is a widely used process in sheet metal components. It is a cutting operation in which material is cut in between punch and dies interface. In this process a piece of sheet metal is removed from a larger piece of stock by applying a enough shearing force. The piece removed, called the blank, is not scrap but rather the desired part. Blanking and piercing are manufacturing processes by which certain geometrical shapes are sheared off a sheet metal. If the sheared off part is the one required, the processes referred to as.Piercing and Blanking • Piercing and blanking are shearing operations where a part is removed from sheet material by forcing a shaped punch through the sheet and into a shaped die • Blanking- the piece being punched out becomes the workpiece • Piercing- the punchout is the scrap and the remaining strip is the workpiece In this article, you will learn the 9 different types of sheet metal operations with diagrams. Also, you can download the pdf file of this post. What is the Sheet Metal Process? The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication.

The sheet metal blanking process consists in separating a blank from a sheet by a punch. It combines material plastic flow and ductile fracture. The main characteristics associated with the blanking operation are the global behavior related to the punch force versus the punch displacement curve and the cut edge shape (burr size).Abstract: This document prescribes a model investigation the effect of potential parameters influencing the blanking process and their interaction.Sheet metal is metal formed by an industrial process into thin, flat pieces. It is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of shapes. Countless everyday objects are constructed with sheet metal. Thicknesses can

Abstract- Metal blanking is a widely used process in high volume production of sheet metal components. Blanking consists of a metal forming operation characterized by complete material separation. Low carbon steel is a very common material used in . PDF | The steel sheet metal blanking is widely used for the manufacture of mechanical parts for automotive industry. The general concept of blanking. | Find, read and cite all the.

does a barn light require an electrical box

Find company research, competitor information, contact details & financial data for WILLCOX METAL FABRICATORS, LLC of San Antonio, TX. Get the latest business insights from Dun & Bradstreet.

blanking process in sheet metal pdf|difference between blanking and fine