how to cover old junction box How to install a ceiling box cover. This video shows how to make wires sticking out of a ceiling safe and attractive by installing a new ceiling box cover. T. Best Metal Fabricators in Vista, CA - Elar Welding, PJJ Welding and Fabrication, Fab Kings, Arc Zone, Ray Neff Metal Fabrication, TMD Fabrication, Mobileweld, McMaster Iron, Martinez Welding, Rough Road Automotive

0 · weatherproof junction box cover

1 · junction cover for electrical box

2 · junction box transparent cover

3 · electrical junction box cover plate

4 · decorative junction box cover plate

5 · decorative junction box cover

6 · decorative electrical junction box covers

7 · 4x4 junction box with cover

This groundbreaking new text connects each welding technique to a useful and creative take-home project, making exercises both practical and personal. To further enhance the learning process, every welding project includes a set of prints with specifications, like those used in production fabrication shops.

You cannot cover any junction box that still has live wires in it. Your best bet is to either remove the box all together or just put a cover plate on it. Your other option is to run a new circuit to the new box and de-energize the circuit to the old box and mark the source wires as "NOT IN . Todays DIY project is learning the options of covering your electrical box when no longer needed or in use!

It looks too small to let in critters so probably won't cause any problem by leaving it in, but the answer below shows what you would use if . Arlington Ceiling Box Cover: http://amzn.to/2jRz8FoMy Favorite Tool: https://amzn.to/3NIFJuOTools We Recommend: https://www.amazon.com/shop/benjaminsahlstrom.

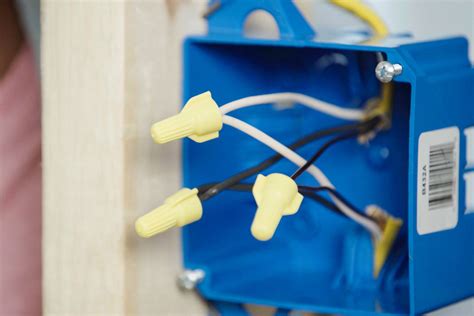

How to install a ceiling box cover. This video shows how to make wires sticking out of a ceiling safe and attractive by installing a new ceiling box cover. T. A junction box covered by a plastic cover is considered identifiable and accessible. A junction box (or worse, a splice hanging in the wall) covered by drywall is not identifiable or . Junction boxes safely house spliced wires, or wire connections, in ceilings, walls and floors and help prevent electrical fires. Unused junction boxes can be secured with blank . As long as there are no wires inside the box, you can cover it with drywall. If the box is still acting as a junction box, however, and wires are joined inside it, the electrical code .

How to Install a Junction Box. A junction box provides a code-approved place to house wire connections, whether for outlets, switches, or splices. Here's how to install one. by Chuck Bickford Updated 09/03/2024.

So long as there is access to that 'new' line/junction box (in the attic). Then all you have is an old hole/box that you need to cover.. Then you can try and remove the old box (possibly)..and block the old hole from behind and install some drywall, - tape, mud and finesse (!!) the area to suitable match to the original wall finish.

This old electrical box is not rated for modern fans. It does not have the the 8-32 screw tabs on two sides. I suggest to remove this old metal box and replace it with a new shallow fan box. Clearly this old box is screwed to a floor . Electrical - AC & DC - Exposed ceiling junction box - fixture doesn't cover fully - I have a light fixture that doesn't cover a standard ceiling box. Any idea what to do with it? . fasten light to ceiling not the box with toggle bolts . Remove the Old Junction Box. Now that you’re in the clear, use your screwdriver to remove any screws holding it in place. . Once everything is connected, carefully push the wires back into the box. If your box has a cover, screw it in place. Make sure the cover is tight, as this keeps the connections safe from dust and moisture. .Don’t screw or nail anything through the box. In the back in the side anywhere. Illegal and asking for trouble. Use the Madison clip, if that is not working, which is possible because of the damaged wall you have to remove the old box from removing it off the stud and use a cutin box Old work box. Or just put a new, new work box in.

To determine how the box is attached you should proceed to remove the box. First remove the flat bar with projecting machine screws. Then look at the inside of the box to see how the box is attached to either a metal bar or to a ceiling joist.Technically, by code, any connections have to be made inside an approved junction box--you can't just splice a piece of wire where you need it. And the wire you use depends on the size/type of wire that you're connecting to. . Splice an extension inside the existing box, run the wire to where it’s needed, and then put a blank cover on the . The old mirror is wired for electric lighting, but the new mirror is just a mirror with no attached lighting fixture. . wrap some electrical tape around them, insert them back into the junction box and cover the box with an approved cover plate. If they are just dangling out of a hole in the drywall/tile, then you need to find out what .You could go to the box that feeds this wire, disconnect this wire from the source. Cut the ens off, and push the wire back through the box and out into the wall. This way it will no longer be accessible from inside the box, and you don't have any live wires inside the wall.

I realize this is old, but I want to share my experience with these fixtures. They make conversion kits, but I couldn't find one large enough to cover the old 14" square fixture. I made my own conversion kit out of a 16" wood circle with a ceiling electrical box mounted in the center. I removed the old socket and hardware from the recessed box. As long as the cover can be accessed to get into the box you can put a blank on them and paint or wall paper over them. If the book shelves have a solid back the back must be cut so the cover can be accessed. You are not permitted to bury junction boxes with live wires. The existing light will be removed and the existing metal junction box will have a white cover plate. I am using a 3/8 inch flexible metal conduit whip ( Southwire 3/8 in. x 6 ft. 14/3 Solid CU Lighting Flexible Whip-55082415 - The Home Depot ) to do this.

The current plan was to pull the old box out, put a new one in about a foot higher up, then run new romex from the new box through the wall, around the corner and then to the new outlet. . Seems like a good time to fish a new wire from the destination to an accessible junction spot. Or a blank cover if it's not in an incredibly inconvenient . Stuff the wires in the hole and put a round blank cover over it. Hardwired smoke alarms, like your old ones, are required to be mounted to mains wiring junction boxes since they run directly off mains electricity, and all splices of or connections to mains electrical wiring in North American need to be made in a junction box. Was wondering if anybody knew of anything I could get to cover up a swimming pool light junction box. A customer of mine had one that was mounted under his diving board. . This is an older thread, you may not receive a response, and could be reviving an old thread. Please consider creating a new thread. Insert Quotes Post Reply .

How to remove old pancake junction box (metal brace, lathe and plaster cieling) 2. safely de-energizing a junction box so that I can permanently cover it up. 1. Mounting Ceiling Fan to Old Junction Box. 4. How to remove old . I removed a Romex cable that was going into a junction box top middle opening(you can see in the picture). . Mount Ceiling Fan to Old Junction Box? 6. Bathroom vanity light with no junction box . Mysterious junction box .

weatherproof junction box cover

junction cover for electrical box

The difference is accessibility. A junction box covered by a plastic cover is considered identifiable and accessible. A junction box (or worse, a splice hanging in the wall) covered by drywall is not identifiable or accessible. . This is an older thread, you may not receive a response, and could be reviving an old thread. Please consider .

Yes. I've had to upgrade a single gang box to a double gang box just to get additional volume when adding cables to an existing junction. The standard you're looking for is NEC Section 314.16: Number of Conductors in Outlet, Device, and Junction Boxes, and Conduit Bodies.I was repairing some drywall and when I removed the old wall I found this junction box buried underneath the old dry wall (house built in 1960). My understanding is that this is against code so my plan was to just put a cover plate over it, but this box has hole spacing of 3.25” apart versus all the other modern ones which I’ve measured at .

junction box transparent cover

The transformer is part of a 4" door cover; there's several joined circuits inside the box so I really don't want to have to replace the box itself. But I can't find a cover that meets these screw holes - they are 7/8" from the opposite sides and 3/8" from the top/bottom (in the pic they are the upper right slot and the bottom left hole).

electrical junction box cover plate

The Wago one appears to address some European standards. Neither of them can be used with metal clad cable, which is what I have entering this box from the adjacent room. I'll have to find some combination of moving this box (or a replacement one) within the limits of the available cable and painting or disguising the box cover for best appearance.You can use the existing junction box that you have there for the cable, assuming that junction box is for another circuit, you can either add another receptacle since it is a square box or break both taps in the existing receptacle and one half is one circuit and the other half is the other circuit. The junction box can be either plastic or metal. @Kris if there is any overload device in the old panel - the use of the box as a junction box is prohibited by code. Also if the panel is converted to a junction box - no overload devices, from what I understand the cover panel will need to be secured with screws.Remove the cover from the junction box you are replacing. Tear off two pieces of masking tape for each connection. Write the number "1" on both pieces. Wrap the tape around both sides of the connection. . Use the old junction box as a guide. Attach the new connectors to the knockouts in the junction box, with the nuts on the inside of the .

what has happened is that the outer jacket of the power cord has shrunk .. cut off the plug from the end of the power cord . strip away some of the outer jacket . firmly grab the wires with one hand and with your other hand push the outer jacket towards the fitting that you show in the picture . you have to keep stroking the power cord because the outer jacket will .

decorative junction box cover plate

I'm installing an exterior junction box where I'm removing an old light fixture. I have a gasket to seal the cover to the box. But how do I seal the hole where the wire goes into the box?

As for wire diameter, .030-inch diameter is a good all-around choice for welding a wide range of metal thicknesses. For welding thicker material at higher total heat levels, use .035-inch wire (or .045-inch wire if it’s within your welder’s output range). Voltage and amperage

how to cover old junction box|junction box transparent cover