3 axis cnc machine definition What is 3-axis machining? This type of machining works along three main directions: X, Y, and Z. Just think out of the box to grasp the concept. X moves you left and right, Y moves you forward and backward, and Z goes . Shop for Stainless Steel Litter Boxes in Cat Litter Boxes. Buy products such as Large Stainless Steel Cat Litter Box with Scoop and Mat Set - Odor, Stain and Rust Resistant, Easy to Clean, .

0 · small 3 axis cnc mill

1 · axis identification in cnc machine

2 · 3 axis vs 5 mill

3 · 3 axis vertical milling machine

4 · 3 axis hobby milling machine

5 · 3 axis cnc milling machine

6 · 3 axis cnc machine price

7 · 2.5 axis milling vs 3

Item as described in great condition. Fast and well packed shipping. Great communication, a great experience all around, thank you. A trust worthy seller with great deals and fair prices on unique variations of all types of art books / doujinshi.

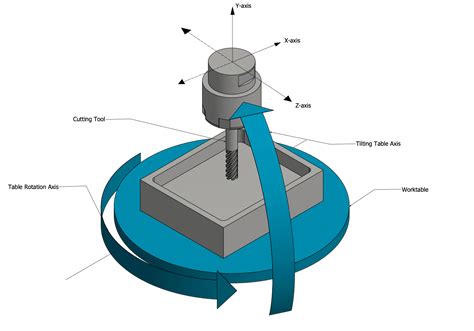

3-axis CNC (computer numerical control) machining is a manufacturing process that uses a computer-controlled cutting tool to remove material from a workpiece. The cutting tool moves in three axes – X, Y, and Z . 3-Axis CNC Milling is a machining process that involves manipulating a workpiece along three different axes simultaneously – X, Y, and Z. This allows for the creation of intricate parts with high accuracy and . The 3 axis CNC machine definition gives the machine the ability to move three different axes at the same time simultaneously. Depending on your machining center, you can upgrade to more axes if needed, at an additional cost. This article details 3-axis CNC mills and briefly describes the differences between 3-axis, 4-axis, and 5-axis CNC mills, which will help you choose the right machine for your needs and ensure optimal productivity and .

What is 3-axis machining? This type of machining works along three main directions: X, Y, and Z. Just think out of the box to grasp the concept. X moves you left and right, Y moves you forward and backward, and Z goes .

The 3-axis CNC machine is one of many types of CNC machines, and it is a device that can create three-dimensional objects by moving a tool along three axes. This type of CNC is perfect for making detailed objects with tight . 3-axis CNC machining refers to the movement of the cutting tool along three axes: X, Y, and Z. The X-axis represents the horizontal movement, the Y-axis represents the vertical movement, and the Z-axis represents the .Three axis CNC machining refers to the ability of the CNC machine to perform movement about three different axis simultaneously. Most CNC manufacturers define their machines movement starting with the three primary axis. X. Y and .

What Is 3-Axis Machining? The manufacturing process referred to as 3-axis machining is a computer numerical control (CNC) method where the cutting tool moves along .

3-axis CNC (computer numerical control) machining is a manufacturing process that uses a computer-controlled cutting tool to remove material from a workpiece. The cutting tool moves in three axes – X, Y, and Z – to create precise cuts and shapes. 3-Axis CNC Milling is a machining process that involves manipulating a workpiece along three different axes simultaneously – X, Y, and Z. This allows for the creation of intricate parts with high accuracy and repeatability, and has led to 3-Axis CNC Milling becoming a favored choice amongst manufacturers across the globe. The 3 axis CNC machine definition gives the machine the ability to move three different axes at the same time simultaneously. Depending on your machining center, you can upgrade to more axes if needed, at an additional cost. In 3-axis machining, the cutting tool moves along the three axes – X, Y, and Z. The X and Y axes represent the horizontal plane, while the Z axis signifies vertical movement. The combined motion in these three axes allows the CNC machine to accurately and efficiently remove material from the workpiece, giving it a desired shape.

This article details 3-axis CNC mills and briefly describes the differences between 3-axis, 4-axis, and 5-axis CNC mills, which will help you choose the right machine for your needs and ensure optimal productivity and quality. What is 3-axis machining? This type of machining works along three main directions: X, Y, and Z. Just think out of the box to grasp the concept. X moves you left and right, Y moves you forward and backward, and Z goes up and down.The 3-axis CNC machine is one of many types of CNC machines, and it is a device that can create three-dimensional objects by moving a tool along three axes. This type of CNC is perfect for making detailed objects with tight tolerances. 3-axis CNC machining refers to the movement of the cutting tool along three axes: X, Y, and Z. The X-axis represents the horizontal movement, the Y-axis represents the vertical movement, and the Z-axis represents the depth or thickness of the material being machined.

Three axis CNC machining refers to the ability of the CNC machine to perform movement about three different axis simultaneously. Most CNC manufacturers define their machines movement starting with the three primary axis. X. Y and Z, with the Z .

small 3 axis cnc mill

axis identification in cnc machine

What Is 3-Axis Machining? The manufacturing process referred to as 3-axis machining is a computer numerical control (CNC) method where the cutting tool moves along three linear axes: X, Y, and Z. These axes correspond to directions: left to right (X), front to back (Y), and up and down (Z).

3-axis CNC (computer numerical control) machining is a manufacturing process that uses a computer-controlled cutting tool to remove material from a workpiece. The cutting tool moves in three axes – X, Y, and Z – to create precise cuts and shapes.

3-Axis CNC Milling is a machining process that involves manipulating a workpiece along three different axes simultaneously – X, Y, and Z. This allows for the creation of intricate parts with high accuracy and repeatability, and has led to 3-Axis CNC Milling becoming a favored choice amongst manufacturers across the globe.

The 3 axis CNC machine definition gives the machine the ability to move three different axes at the same time simultaneously. Depending on your machining center, you can upgrade to more axes if needed, at an additional cost.

In 3-axis machining, the cutting tool moves along the three axes – X, Y, and Z. The X and Y axes represent the horizontal plane, while the Z axis signifies vertical movement. The combined motion in these three axes allows the CNC machine to accurately and efficiently remove material from the workpiece, giving it a desired shape. This article details 3-axis CNC mills and briefly describes the differences between 3-axis, 4-axis, and 5-axis CNC mills, which will help you choose the right machine for your needs and ensure optimal productivity and quality. What is 3-axis machining? This type of machining works along three main directions: X, Y, and Z. Just think out of the box to grasp the concept. X moves you left and right, Y moves you forward and backward, and Z goes up and down.The 3-axis CNC machine is one of many types of CNC machines, and it is a device that can create three-dimensional objects by moving a tool along three axes. This type of CNC is perfect for making detailed objects with tight tolerances.

3-axis CNC machining refers to the movement of the cutting tool along three axes: X, Y, and Z. The X-axis represents the horizontal movement, the Y-axis represents the vertical movement, and the Z-axis represents the depth or thickness of the material being machined.Three axis CNC machining refers to the ability of the CNC machine to perform movement about three different axis simultaneously. Most CNC manufacturers define their machines movement starting with the three primary axis. X. Y and Z, with the Z .

3 axis vs 5 mill

3 axis vertical milling machine

For about $25, the Square Box Speaker 2 is a great Bluetooth speaker that will satisfy your basic listening needs, but if you can, get the metallic model for less than $10 more, which offers not only superior sound and build quality but also broader functionality, including a dedicated micro SD slot. If you are looking to upgrade from the .

3 axis cnc machine definition|3 axis vs 5 mill