3 axis cnc machine video After getting many requests for CNC machining services over the years, but with the same 2-3 day manufacturing turnaround time our clients have come to expec. The Y-Factor is simply a variable based of the more commonly used K-Factor. It is derived by taking half of the K-Factor multiplied by pi. The Y-Factor is used, as far as I know, solely by PTC’s Pro-Engineer, now known as Creo Elements/Pro.

0 · small 3 axis cnc mill

1 · axis identification in cnc machine

2 · 3 axis vs 5 mill

3 · 3 axis vertical milling machine

4 · 3 axis hobby milling machine

5 · 3 axis cnc milling machine

6 · 3 axis cnc machine price

7 · 2.5 axis milling vs 3

You won’t get points on your licence for stopping in a yellow box junction, but the penalty charge can leave a nasty taste in your mouth if you feel it’s unfair. How and where can I appeal?

#cncmachines In this video you’re going to learn about the different types of CNC machines. We’ll cover the benefits and limitations of each machine, and how. This video shows the operation process from start-up to machining completion.

After getting many requests for CNC machining services over the years, but with the same 2-3 day manufacturing turnaround time our clients have come to expec.The MR-1 Gantry Mill is a 3-Axis vertical CNC milling machine that was designed specifically for hobbyist, light industrial, and educational uses. MR-1 features the power and rigidity to remove . Find out which industries are using CNC machining and how they’re applying it. Discover the advantages of CNC machining over traditional machining methods. An in-depth .

3-Axis vs. 5-Axis: Pros and Cons. The main difference between these two types of CNC machines is the number of ways they can move their tool: one has three, and one has five. This seemingly small factor, however, makes . 3-axis CNC (computer numerical control) machining is a manufacturing process that uses a computer-controlled cutting tool to remove material from a workpiece. The cutting tool moves in three axes – X, Y, and Z .In this article, we will master techniques that optimize 3-axis machining. We will uncover how to achieve intricate designs with the utmost precision. 1. The Core Fundamentals of Precision 3-Axis CNC Machining. The 3-axis machining .#cncmachines In this video you’re going to learn about the different types of CNC machines. We’ll cover the benefits and limitations of each machine, and how.

This video shows the operation process from start-up to machining completion.After getting many requests for CNC machining services over the years, but with the same 2-3 day manufacturing turnaround time our clients have come to expec.

3-axis CNC milling machines manufacture parts with relatively simple geometries with excellent accuracy and at a low cost. CNC lathes have the lowest cost per unit, but are only suitable for part geometries with rotational symmetry.The MR-1 Gantry Mill is a 3-Axis vertical CNC milling machine that was designed specifically for hobbyist, light industrial, and educational uses. MR-1 features the power and rigidity to remove 30 pounds of steel per hour and the accuracy and precision to hold tight tolerances. Find out which industries are using CNC machining and how they’re applying it. Discover the advantages of CNC machining over traditional machining methods. An in-depth look at 3, 4 and 5-axis machining, and the circumstances for using each one explained.

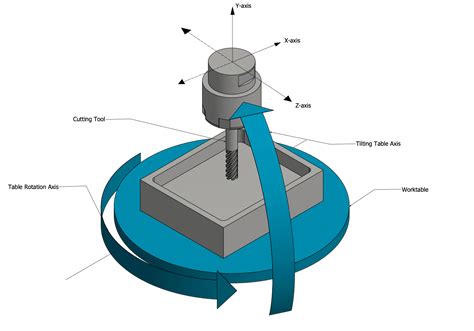

3-Axis vs. 5-Axis: Pros and Cons. The main difference between these two types of CNC machines is the number of ways they can move their tool: one has three, and one has five. This seemingly small factor, however, makes a world of difference, as you can see in the side-by-side comparison table below. 3-axis CNC (computer numerical control) machining is a manufacturing process that uses a computer-controlled cutting tool to remove material from a workpiece. The cutting tool moves in three axes – X, Y, and Z – to create precise cuts and shapes.

In this article, we will master techniques that optimize 3-axis machining. We will uncover how to achieve intricate designs with the utmost precision. 1. The Core Fundamentals of Precision 3-Axis CNC Machining. The 3-axis machining process manipulates both the piece of material and the cutting tool in three directions, known as X, Y, and Z axes. A 3-axis machine usually does the job perfectly at lower prices than a 5-axis machine. However, do you want to learn more about this milling machine? Let’s explore every detail!#cncmachines In this video you’re going to learn about the different types of CNC machines. We’ll cover the benefits and limitations of each machine, and how.

small 3 axis cnc mill

This video shows the operation process from start-up to machining completion.After getting many requests for CNC machining services over the years, but with the same 2-3 day manufacturing turnaround time our clients have come to expec.

junction box for 1 1 4 inch emt

3-axis CNC milling machines manufacture parts with relatively simple geometries with excellent accuracy and at a low cost. CNC lathes have the lowest cost per unit, but are only suitable for part geometries with rotational symmetry.The MR-1 Gantry Mill is a 3-Axis vertical CNC milling machine that was designed specifically for hobbyist, light industrial, and educational uses. MR-1 features the power and rigidity to remove 30 pounds of steel per hour and the accuracy and precision to hold tight tolerances.

Find out which industries are using CNC machining and how they’re applying it. Discover the advantages of CNC machining over traditional machining methods. An in-depth look at 3, 4 and 5-axis machining, and the circumstances for using each one explained. 3-Axis vs. 5-Axis: Pros and Cons. The main difference between these two types of CNC machines is the number of ways they can move their tool: one has three, and one has five. This seemingly small factor, however, makes a world of difference, as you can see in the side-by-side comparison table below. 3-axis CNC (computer numerical control) machining is a manufacturing process that uses a computer-controlled cutting tool to remove material from a workpiece. The cutting tool moves in three axes – X, Y, and Z – to create precise cuts and shapes.In this article, we will master techniques that optimize 3-axis machining. We will uncover how to achieve intricate designs with the utmost precision. 1. The Core Fundamentals of Precision 3-Axis CNC Machining. The 3-axis machining process manipulates both the piece of material and the cutting tool in three directions, known as X, Y, and Z axes.

axis identification in cnc machine

3 axis vs 5 mill

Explore nine striking metal roof and siding color combinations for modern homes that will enhance your home's curb appeal and make it stand out from the rest.When you want the complete vibrant look, pair a green metal roof with a yellow house. Green and yellow is a popular combination that has a fresh and bright appearance. .

3 axis cnc machine video|small 3 axis cnc mill