3 axis cnc machine wiki There are three main components to multiaxis machines: The machines physical capabilities i.e. torque, spindle speed, axis orientation/operation. The CNC drive system, the components that move the machine. This includes servo-motors, rapid traverse systems, ball screws, and how positioning is monitored. See more Set the Smoker Box right on top of your cooking grates to transform any gas grill into a smoke cooker to give your meats, veggies, nuts, and cheeses the .

0 · small 3 axis cnc mill

1 · axis identification in cnc machine

2 · 3 axis vs 5 mill

3 · 3 axis vertical milling machine

4 · 3 axis hobby milling machine

5 · 3 axis cnc milling machine

6 · 3 axis cnc machine price

7 · 2.5 axis milling vs 3

Free U.S. Shipping

There are three main components to multiaxis machines: The machines physical capabilities i.e. torque, spindle speed, axis orientation/operation. The CNC drive system, the components that move the machine. This includes servo-motors, rapid traverse systems, ball screws, and how positioning is monitored. See moreMultiaxis machining is a manufacturing process that involves tools that move in 4 or more directions and are used to manufacture parts out of metal or other materials by milling away excess material, by See moreMultiaxis CNC machines are used in many industries including:• Aerospace industry: Multiaxis machines are used in the . See more

• Machine tool• Milling machine• Numerical control• CNC pocket milling See moreCAM software automates the process of converting 3D models into tool paths, the route the multiaxis machine takes to mill a part (Fig. 1). This software takes into account the different . See moreCNC routers come in many configurations, from small home-style D.I.Y. "desktop", to large industrial routers manufactured for commercial use. CNC routers are used in sign shops, cabinet making, aerospace and boat-making. Although there are many configurations, most CNC routers have a few specific parts: a dedicated CNC controller, one or more spindle motors, servo motors or stepper motors, servo amplifiers, A. 3-axis CNC (computer numerical control) machining is a manufacturing process that uses a computer-controlled cutting tool to remove material from a workpiece. The cutting tool moves in three axes – X, Y, and Z .

Most CNC milling machines (also called machining centers) are computer controlled vertical mills with the ability to move the spindle vertically .

small 3 axis cnc mill

3-Axis CNC Milling is a machining process that involves manipulating a workpiece along three different axes simultaneously – X, Y, and Z. This allows for the creation of intricate parts with high accuracy and . 3-axis CNC machining refers to the ability of a CNC machine to move along three axes: X, Y, and Z. This allows for the creation of complex shapes and intricate designs with high precision. The capabilities of 3-axis . The manufacturing process referred to as 3-axis machining is a computer numerical control (CNC) method where the cutting tool moves along three linear axes: X, Y, . Are you wondering what 3 axis CNC machine systems are and how to use them? Do you want to know why the 3 axis option still stands strong even among higher multi-axis alternatives?

There are three main components to multiaxis machines: The machines physical capabilities i.e. torque, spindle speed, axis orientation/operation. The CNC drive system, the components that move the machine. This includes servo-motors, rapid traverse systems, ball screws, and how positioning is monitored.

axis identification in cnc machine

CNC routers are typically available in 3-axis and 5-axis CNC formats. Many manufacturers offer A and B axis for full 5-axis capabilities and rotary 4th axis. Common industrial CNC router sizes include 4 × 8 feet and 5 × 10 feet. 3-axis CNC (computer numerical control) machining is a manufacturing process that uses a computer-controlled cutting tool to remove material from a workpiece. The cutting tool moves in three axes – X, Y, and Z – to create precise cuts and shapes.

Most CNC milling machines (also called machining centers) are computer controlled vertical mills with the ability to move the spindle vertically along the Z-axis. This extra degree of freedom permits their use in diesinking, engraving applications, and 2.5D surfaces such as .

3-Axis CNC Milling is a machining process that involves manipulating a workpiece along three different axes simultaneously – X, Y, and Z. This allows for the creation of intricate parts with high accuracy and repeatability, and has led to 3-Axis CNC Milling becoming a favored choice amongst manufacturers across the globe. 3-axis CNC machining refers to the ability of a CNC machine to move along three axes: X, Y, and Z. This allows for the creation of complex shapes and intricate designs with high precision. The capabilities of 3-axis CNC machining are vast and include:

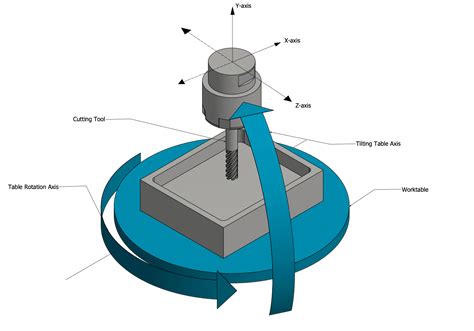

The manufacturing process referred to as 3-axis machining is a computer numerical control (CNC) method where the cutting tool moves along three linear axes: X, Y, and Z. These axes correspond to directions: left to right (X), front to back (Y), and up and down (Z). Are you wondering what 3 axis CNC machine systems are and how to use them? Do you want to know why the 3 axis option still stands strong even among higher multi-axis alternatives?Three axis CNC machining refers to the ability of the CNC machine to perform movement about three different axis simultaneously. Most CNC manufacturers define their machines movement starting with the three primary axis. X. Y and Z, with the Z .

how to count conduits in junction box

When one hears about 3-axis milling, they dive into the most common form of CNC milling. But what does it truly entail? At its simplest, 3-axis machining involves three primary directions of movement – horizontally along the X-axis, vertically along the Y-axis, and depth-wise along the Z-axis.There are three main components to multiaxis machines: The machines physical capabilities i.e. torque, spindle speed, axis orientation/operation. The CNC drive system, the components that move the machine. This includes servo-motors, rapid traverse systems, ball screws, and how positioning is monitored.

CNC routers are typically available in 3-axis and 5-axis CNC formats. Many manufacturers offer A and B axis for full 5-axis capabilities and rotary 4th axis. Common industrial CNC router sizes include 4 × 8 feet and 5 × 10 feet. 3-axis CNC (computer numerical control) machining is a manufacturing process that uses a computer-controlled cutting tool to remove material from a workpiece. The cutting tool moves in three axes – X, Y, and Z – to create precise cuts and shapes.Most CNC milling machines (also called machining centers) are computer controlled vertical mills with the ability to move the spindle vertically along the Z-axis. This extra degree of freedom permits their use in diesinking, engraving applications, and 2.5D surfaces such as .

3-Axis CNC Milling is a machining process that involves manipulating a workpiece along three different axes simultaneously – X, Y, and Z. This allows for the creation of intricate parts with high accuracy and repeatability, and has led to 3-Axis CNC Milling becoming a favored choice amongst manufacturers across the globe. 3-axis CNC machining refers to the ability of a CNC machine to move along three axes: X, Y, and Z. This allows for the creation of complex shapes and intricate designs with high precision. The capabilities of 3-axis CNC machining are vast and include: The manufacturing process referred to as 3-axis machining is a computer numerical control (CNC) method where the cutting tool moves along three linear axes: X, Y, and Z. These axes correspond to directions: left to right (X), front to back (Y), and up and down (Z). Are you wondering what 3 axis CNC machine systems are and how to use them? Do you want to know why the 3 axis option still stands strong even among higher multi-axis alternatives?

how to cover a metal bed frame with fabric

Three axis CNC machining refers to the ability of the CNC machine to perform movement about three different axis simultaneously. Most CNC manufacturers define their machines movement starting with the three primary axis. X. Y and Z, with the Z .

3 axis vs 5 mill

(a) All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box shall have a cover, faceplate, or fixture canopy.

3 axis cnc machine wiki|3 axis vertical milling machine