electrical box that that attached by screw in the middle Place the new receptacle back in its electrical box by folding the wires, pushing the receptacle into place, and attaching it with two screws. Cover with the faceplate, turn the power back on, and test.

Our on-demand manufacturing platform can deliver high-quality metal and plastic CNC turning parts for rapid prototyping or low-to-high volume production runs. Get an instant quote from your 3D CAD file today. Additional alloys and tempers are available upon request. We can source to your project specifications.

0 · wiring screw hole in center

1 · screws for electrical box

2 · recessed outlet screws

3 · electrical box screw size chart

Buy grease, bearings, RS232 cables, surface plates, maintenance tools, CNC software, oil, training software and industrial supplies. Authorized distributor for thousands of electrical parts. Call Us (414)881-4493

For a light switch, that means a nice big surface to press (unless split into 2 or 3 switches). For receptacles, that means no screw in the middle. But I think the most common reason to switch to Decora (or to any equivalent size from any other manufacturer) is GFCI. The most common size screw to use in an electric box is a 6-32 flathead screw. For heavier applications, like ceiling lighting and ceiling fans, an 8-32 screw will work better. Ground screws in electrical boxes are always 10-32 . Nails and screws, where used as a fastening means, shall secure boxes by using brackets on the outside of the enclosure, or by using mounting .

You've changed an outlet and now the screw isn't long enough - what screw do you need? If you need a replacement or longer screw for an outlet, switch or electrical box I’ll show you in. Problem is- exactly where I want to put the electrical box to hang the wall light is a wall 2×4 stud. what can I do – use one of those thinner electrical boxes and cut out part of the . Place the new receptacle back in its electrical box by folding the wires, pushing the receptacle into place, and attaching it with two screws. Cover with the faceplate, turn the power back on, and test.

Exterior boxes should be attached with screws; the back of the box should have small holes for that purpose. If you have a metal box, use a screwdriver as a lever to remove the knockouts (the precut metal discs on . What is the best (or correct) way to wire outlets in the middle of a circuit? 1) Using the screws available in the outlet to "extend" the circuit wires to the next outlet. 2) Making a derivation .

When you need to install an electrical box in a specific location and there is no stud to attach it to, we call that ReWork -- getting a box in where it is impossible or difficult to attach to a stud. I'd just cut off the nailing ears, insert the box through the existing drywall hole, and attach it using a screw (or two) through the sides of the box into the stud. I'm thinking maybe . For a light switch, that means a nice big surface to press (unless split into 2 or 3 switches). For receptacles, that means no screw in the middle. But I think the most common reason to switch to Decora (or to any equivalent size from any other manufacturer) is GFCI.

wiring screw hole in center

The most common size screw to use in an electric box is a 6-32 flathead screw. For heavier applications, like ceiling lighting and ceiling fans, an 8-32 screw will work better. Ground screws in electrical boxes are always 10-32 and must be painted visibly green. Nails and screws, where used as a fastening means, shall secure boxes by using brackets on the outside of the enclosure, or by using mounting holes in the back or in a single side of the enclosure, or they shall pass through the interior . We used to pretty much only use hex head #10 or #12 screws for boxes and whatnot. Lately we started using phillips "truss head" #8 screws for mounting boxes and clips, and they aren't too shabby. They are also 1/2 the cost per fastener, which adds up for the number of screws I go through a year. You've changed an outlet and now the screw isn't long enough - what screw do you need? If you need a replacement or longer screw for an outlet, switch or electrical box I’ll show you in.

Problem is- exactly where I want to put the electrical box to hang the wall light is a wall 2×4 stud. what can I do – use one of those thinner electrical boxes and cut out part of the face of the stud with Mr Sawzall? Or use a round 1/2" deep pan box & cut out drywall only and mount to the stud surface . Place the new receptacle back in its electrical box by folding the wires, pushing the receptacle into place, and attaching it with two screws. Cover with the faceplate, turn the power back on, and test.

Exterior boxes should be attached with screws; the back of the box should have small holes for that purpose. If you have a metal box, use a screwdriver as a lever to remove the knockouts (the precut metal discs on either side of the box).

What is the best (or correct) way to wire outlets in the middle of a circuit? 1) Using the screws available in the outlet to "extend" the circuit wires to the next outlet. 2) Making a derivation . When you need to install an electrical box in a specific location and there is no stud to attach it to, we call that ReWork -- getting a box in where it is impossible or difficult to attach to a stud. For a light switch, that means a nice big surface to press (unless split into 2 or 3 switches). For receptacles, that means no screw in the middle. But I think the most common reason to switch to Decora (or to any equivalent size from any other manufacturer) is GFCI.

The most common size screw to use in an electric box is a 6-32 flathead screw. For heavier applications, like ceiling lighting and ceiling fans, an 8-32 screw will work better. Ground screws in electrical boxes are always 10-32 and must be painted visibly green. Nails and screws, where used as a fastening means, shall secure boxes by using brackets on the outside of the enclosure, or by using mounting holes in the back or in a single side of the enclosure, or they shall pass through the interior .

We used to pretty much only use hex head #10 or #12 screws for boxes and whatnot. Lately we started using phillips "truss head" #8 screws for mounting boxes and clips, and they aren't too shabby. They are also 1/2 the cost per fastener, which adds up for the number of screws I go through a year. You've changed an outlet and now the screw isn't long enough - what screw do you need? If you need a replacement or longer screw for an outlet, switch or electrical box I’ll show you in.

screws for electrical box

Problem is- exactly where I want to put the electrical box to hang the wall light is a wall 2×4 stud. what can I do – use one of those thinner electrical boxes and cut out part of the face of the stud with Mr Sawzall? Or use a round 1/2" deep pan box & cut out drywall only and mount to the stud surface . Place the new receptacle back in its electrical box by folding the wires, pushing the receptacle into place, and attaching it with two screws. Cover with the faceplate, turn the power back on, and test. Exterior boxes should be attached with screws; the back of the box should have small holes for that purpose. If you have a metal box, use a screwdriver as a lever to remove the knockouts (the precut metal discs on either side of the box). What is the best (or correct) way to wire outlets in the middle of a circuit? 1) Using the screws available in the outlet to "extend" the circuit wires to the next outlet. 2) Making a derivation .

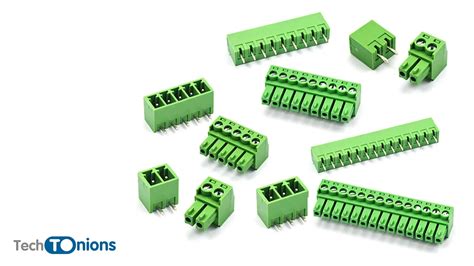

junction box right angle

junction box right angle

Custom CNC turning services with fast lead times and competitive pricing from rapid prototyping to production runs. 0.005 mm tight tolerance. Lead time as fast as 1 day. Start A New CNC Quote

electrical box that that attached by screw in the middle|wiring screw hole in center