nc/cnc machine tools and systems Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages . Finding the upper level Junction Box in The Wells in Starfield In The Wells, you need to find a bar called Jake’s, which is located right underneath the quest marker for the Junction Box. Jake’s has a red “J” logo and has a few different entrances and exits.Marvel Spiderman - Wheels within Wheels - Find and Activate Junction box puzzle.Join Amazon Prime for Free : https://amzn.to/33mM7AsBuy External PS4 Game Dri.

0 · structure of cnc machine tools

1 · numerically controlled machines

2 · numerically controlled machine tools

3 · how cnc machine is controlled

4 · computer numerically controlled machine tools

5 · computer numerical control machines

6 · cnc machine what is it

7 · block diagram of nc machine

$22.99

Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages .

In the NC machine, the programs are fed into the punch cards.Whereas in CNC machine the programs are fed directly into the computer by a small keyboard similar to our traditional keyboard.. In the NC machine, .

28. Mechanical Engineering Department 28 CNC Controllers The NC controller is the brain of the NC system, it controls all functions of the machine. • Motion control deals with the tool position, orientation and speed. • . 2. Workpiece of CNC system:- The external appearance of CNC system is similar to that of conventional NC system. The tape reader is used for reading part program into computer memory. The computer hardware .Study with Quizlet and memorize flashcards containing terms like What two types of manufacturing processes can a hybrid CNC perform?, What type of CNC machine brings tools into contact with a rotating workpiece?, What component .

The first CNC machine, a Cincinnati Hydrotel milling machine retrofitted with a computer control system, was introduced in the early 1960s. As computing technology advanced, CNC systems evolved from punch-card readers to more sophisticated computer interfaces. The 1970s saw the adoption of microprocessors, which improved the processing speed .A CNC machine that operates on wood CNC machines typically use some kind of coolant, typically a water-miscible oil, to keep the tool and parts from getting hot. A CNC metal lathe with the door open.. In machining, numerical control, also called computer numerical control (CNC), [1] is the automated control of tools by means of a computer. [2] It is used to operate tools such . HISTORY • The first NC machines were built in the 1940s and 1950s by Prof. John T Parson. • CNC machine came into existence after evolution of computer around 1980. . system in which the data handling, control sequences, and response to input is determined by an on-board computer system at the machine tool. 5. TYPES OF CNC MACHINE . The feed servo control system of the modern CNC machine tool is a servo system with the digital controller PID as the core.Since the system have bot h analog and digital signal devices, the theory of

structure of cnc machine tools

4. • By power supply: NC systems can be classified as hydraulic, electric, or pneumatic. Hydraulic system use fluid pressure to move the machine tools, electric systems use electrical motors, and pneumatic systems use compressed air. • By manufacturing method: NC systems can be classified as universal or dedicated. Universal systems are designed to be . In this article, I shall share knowledge about NC machines. I will explore its definition, parts, types, working principles, advantages, disadvantages, and applications. I have also given a PDF for the same. What are NC Machines. An NC Machine stands for Numerical Control Machine it is the predecessor of CNC Machine. It is a manufacturing .5 In CNC systems multiple microprocessors and programmable logic controllers work _____ A in series. B in parallel. C for 80% of the total machining time. . Answer: The control unit of NC machine tool works in batch processing mode and the control unit of CNC machine tool works in ON-line mode 18 In NC (Numerical Control) .

numerically controlled machines

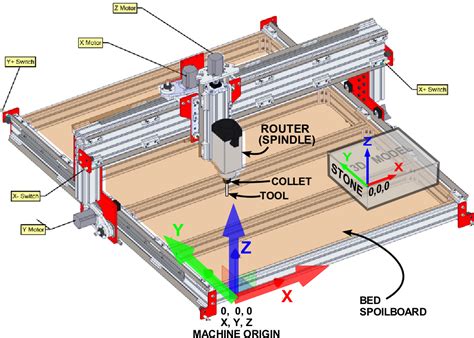

2. v CNC MACHINES o Modern manufacturing systems are advanced automation systems. The numerical control (NC) and computer numerical control (CNC) machines are an integral part of the automation systems. o CNC machining is capable of meeting the tightest tolerances, and producing the most accurate, precise products over and over again.The basic components of an NC system include the machine control unit, program input, machine tool, and feedback system. NC machines use coordinate systems such as Cartesian and polar systems to define the position and movement of the machine tool. Motion control systems are responsible for controlling the movement of the machine tool.

7. CNC Machine To overcome the shortcomings of the NC machines CNC machines evolved. CNC machines are the NC machines whose MCU is based on the micro computer rather than the hardwired controller. Elements of CNC machines are Part program Machine Control Unit Machine tool Features of CNC machines are: Storage of more than one . Request PDF | Iterative NC program modification and energy saving for a CNC machine tool feed drive system with linear motors | This study proposes a design of iterative learning contouring .

All included G-Code files in this project will be overridden with the following values. Feed Rate (inches per minute) is the speed at which your torch moves as it is cutting.. Pierce Delay (seconds) is the time the torch spends at the start location to pierce the material before starting to move along the cut path.Study with Quizlet and memorize flashcards containing terms like What benefits of NC became apparent early in their use? NC:, Which statement about the benefits of CNC is true? CNC machines:, What is the major difference between NC and CNC systems? and more.Computer Numerical Control (CNC) controllers are high value-added products counting for over 30% of the price of machine tools. The development of CNC technology depends on the integration of technologies from many different industries, and .

Authors and Affiliations. School of Mechatronics Engineering, Harbin Institute of Technology, Harbin, 150001, People’s Republic of China. Gangwei Cui, Yong Lu, Jianguang Li, Dong Gao & Yingxue Yao The sound of chips hitting the machine has people flocking to the Ibarmia stand at AMB 2024!! Whether it’s the T series or the Z series, Ibarmia’s Gen2 models have so many different options you wouldn’t normally see at any exhibition. From standard milling and turning all the way to skiving, eccentric turning, elliptic turning, [.] The first generation of CNC machine tools: NC systems using electronic tube components were used from 1952 to 1959. The second generation of CNC machine tools: NC systems using transistor circuits were adopted since 1959. The third generation of CNC machine tools: NC systems using small and medium-scale integrated circuits were adopted since 1965.

CNC machine tools are currently predominating in the machine-building industry. Generally, these machine tools are equipped with control systems supplied by the world's leading manufacturers, such as Siemens and Fanuc are very expensive. In parallel, many cheap amateur and semi-professional CNC machine tool solutions are being developed.NC systems, which define the difference between nc machine and cnc machine, use fixed logical functions to handle a machine’s tool or a machining process. The NC specifies the control of the movements of the machine and various different functions with the help of instructions indicated as a sequence of numbers.“CNC is a self-contained NC system for a single machine tool which uses a dedicated minicomputer, controlled by the instruction stored in its memory, to perform all the basic numerical control functions.

china 3d cnc wire bending machine manufacturer

The NC (Numeric Control) and CNC (Computer Numeric Control) are the systems implemented with the various machining tools in the various industries and factories. These Controls mainly differentiated by the fact that NC is the traditional control which allows the use of prerecorded information in the machining process.

Study with Quizlet and memorize flashcards containing terms like What part of a CNC system reads and executes the machining instructions in the part program?, What is the purpose of a CNC machining center? Machining centers enable a single machine to:, Which of the following is an advantage of CNC systems? CNC systems: and more. After countless after-hours research and communication with an engineering team, Steve received his first R&D CNC table delivered to the farm in October of 2020. Nearly 3 years later, Phantom CNC Systems is in 2nd generation (Reaper and Shadow) of machines in both 4' x 8' and 5' x 10' configurations.

numerically controlled machine tools

I plan on classifying my material down to at least 1/4" so would expanded metal work as well as small riffles or should I use both? The area will also more.

nc/cnc machine tools and systems|cnc machine what is it