additive manufacturing vs cnc Additive manufacturing allows for complex geometries and customization, while CNC machining offers high precision and speed. The choice between these techniques depends on factors . This IPEX JB444 4 x 4 x 4 inch PVC Conduit Junction Box is brand new in the original factory packaging. Supplies Depot has free shipping on orders over $99. We have plumbing, heating, electrical supplies and more in stock at our warehouse at nationally competitive prices.

0 · difference between cnc and am

1 · difference between cnc and additive manufacturing

2 · cnc machining vs am

Established in 1982, Western Metal Products specializes in Architectural Sheet Metal for the Commercial and Residential markets. With projects spread across the United States we have earned a solid reputation of on time quality .

The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while .

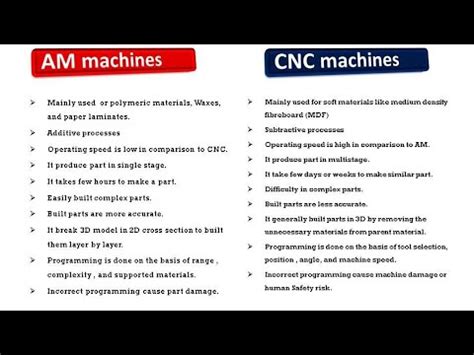

Both AM and CNC Machining have their pros and cons, and the choice between them depends on specific project requirements. The convergence of AM and CNC Machining offers a hybrid manufacturing solution with improved efficiency and .Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is .Two of the most dominant manufacturing technologies in the industry today are Additive Manufacturing (AM) and CNC (Computer Numerical Control) Machining. While both have their .

Additive manufacturing allows for complex geometries and customization, while CNC machining offers high precision and speed. The choice between these techniques depends on factors . Boeing and other manufacturers use three primary criteria to measure the value of additive manufacturing (AM) against CNC Machining: part performance, cost and lead time .CNC machining is a subtractive process wherein raw material is carefully removed by cutting tools controlled by a computer. With this precise and versatile technique, manufacturers can . There is cause for debate as to which is the more suitable method of tooling fabrication: CNC milling, lathes, etc., or 3D printing via additive manufacturing. There are three notable advantages to using additive .

Additive manufacturing and CNC manufacturing are two popular production techniques that produce precise and functional metal parts fast and efficiently. Both are powerful and sophisticated manufacturing resources that bring any . The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while CNC machining subtracts material to achieve high precision, repeatability, and smooth finishes in production.Both AM and CNC Machining have their pros and cons, and the choice between them depends on specific project requirements. The convergence of AM and CNC Machining offers a hybrid manufacturing solution with improved efficiency and flexibility.

While both processes have the ability to work with metal and produce components, there are significant differences. Additive manufacturing is the process of creating a component through the distribution of powder material and an adhesive binder.Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is crucial for businesses and designers looking to improve their new product development processes.Two of the most dominant manufacturing technologies in the industry today are Additive Manufacturing (AM) and CNC (Computer Numerical Control) Machining. While both have their unique advantages, they serve diverse purposes and function with distinct mechanisms.Additive manufacturing allows for complex geometries and customization, while CNC machining offers high precision and speed. The choice between these techniques depends on factors such as the desired part characteristics, volume of production, lead time, and cost considerations.

Boeing and other manufacturers use three primary criteria to measure the value of additive manufacturing (AM) against CNC Machining: part performance, cost and lead time (see our blog post on this). In the past, metal AM processes were expensive and slow.

CNC machining is a subtractive process wherein raw material is carefully removed by cutting tools controlled by a computer. With this precise and versatile technique, manufacturers can produce complex, three-dimensional parts with exceptional accuracy. There is cause for debate as to which is the more suitable method of tooling fabrication: CNC milling, lathes, etc., or 3D printing via additive manufacturing. There are three notable advantages to using additive manufacturing or 3D printing when manufacturing parts, tools, and forms.Additive manufacturing and CNC manufacturing are two popular production techniques that produce precise and functional metal parts fast and efficiently. Both are powerful and sophisticated manufacturing resources that bring any design concept to life.

difference between cnc and am

The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while CNC machining subtracts material to achieve high precision, repeatability, and smooth finishes in production.Both AM and CNC Machining have their pros and cons, and the choice between them depends on specific project requirements. The convergence of AM and CNC Machining offers a hybrid manufacturing solution with improved efficiency and flexibility.

While both processes have the ability to work with metal and produce components, there are significant differences. Additive manufacturing is the process of creating a component through the distribution of powder material and an adhesive binder.

Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is crucial for businesses and designers looking to improve their new product development processes.Two of the most dominant manufacturing technologies in the industry today are Additive Manufacturing (AM) and CNC (Computer Numerical Control) Machining. While both have their unique advantages, they serve diverse purposes and function with distinct mechanisms.Additive manufacturing allows for complex geometries and customization, while CNC machining offers high precision and speed. The choice between these techniques depends on factors such as the desired part characteristics, volume of production, lead time, and cost considerations.

Boeing and other manufacturers use three primary criteria to measure the value of additive manufacturing (AM) against CNC Machining: part performance, cost and lead time (see our blog post on this). In the past, metal AM processes were expensive and slow.CNC machining is a subtractive process wherein raw material is carefully removed by cutting tools controlled by a computer. With this precise and versatile technique, manufacturers can produce complex, three-dimensional parts with exceptional accuracy. There is cause for debate as to which is the more suitable method of tooling fabrication: CNC milling, lathes, etc., or 3D printing via additive manufacturing. There are three notable advantages to using additive manufacturing or 3D printing when manufacturing parts, tools, and forms.

difference between cnc and additive manufacturing

cnc foam router machine

cnc gantry drilling machine suppliers

cnc machining vs am

Junction boxes are rated in amps (typically 5, 20 or 30 amp). The size used should equate to the current rating of the circuit being connected into - you can always use a higher rated box than the circuit but never a lower rated box. For a lighting circuit use a 20amp junction box and for a ring main or radial circuit use a 30 amp junction box.

additive manufacturing vs cnc|cnc machining vs am