cnc machine carbon fiber Machining carbon fiber presents several significant challenges, including tool wear and damage, delamination and fiber pullout, dust and health hazards, heat generation and thermal damage, and achieving a desired surface finish and . If you are caught in a yellow box junction, and your vehicle has come to a stop, you are in danger of receiving a yellow box junction fine. You should only enter if your exit is clear, and if traffic conditions prevent you from clearing the junction, you .

0 · water jet cutting carbon fiber

1 · how to cut carbon fibre

2 · end mill for carbon fiber

3 · desktop cnc for carbon fiber

4 · cnc carbon fiber sheets

5 · cnc carbon fiber cutting service

6 · carbon fiber machining near me

7 · carbon fiber cnc cutting

When performing precision shaft alignment on horizontal rotating machinery, the Z axis refers to the rotational axis or rotational centerlines. The Y axis refers to vertical position (perpendicular to the base) and the X axis refers to the horizontal position (parallel to the base). As seen in Figure 6a below.

Carbon fiber surpasses conventional CNC machining materials such as aluminum, steel, wood, or glass. It creates high-performance, durable, and low-weight components. Machining carbon fiber sheets is generally .

newage products bold series black 12-piece steel garage cabinet set

Machining carbon fiber presents several significant challenges, including tool wear and damage, delamination and fiber pullout, dust and health hazards, heat generation and thermal damage, and achieving a desired surface finish and . FRP (fiber-reinforced plastic) composites are produced from strands of aramid, carbon, glass or other fibrous synthetics. These reinforcements are bound together using some resin, typically a thermoset or thermoplastic . Carbon fibers are lightweight composites known for their high strength, low weight, durability, impact resistance, and many other beneficial properties for countless industrial applications. These composite parts are .

water jet cutting carbon fiber

Machining carbon fiber promises superior-quality finished components characterized by lightness and rigidity. It allows you to craft unique carbon fiber constituents in line with your specific use requirements. We use Autodesk Fusion 360, configure the CAM settings, generate the G-Code, setup the Stepcraft router and then start the machining process. .more. Detailed video tutorial covering all the.

Detailed tutorial explaining how to generate toolpaths using Autodesk Fusion 360, configure CAM setting and a desktop CNC router to make your own precision cut carbon fibre .The precision, accuracy, and efficiency of CNC machines make them invaluable tools in industries that rely on carbon fiber for high-performance applications. By investing in the right CNC .Machining Carbon Fiber Sheets - Cutting and drilling CFRP easily and precisly with a CNC milling machine. Make clean cutting edges and drill holes. Carbon Fiber and Composites have special machining challenges. Discover the tips, techniques, and tooling needed for successful machining.

how to cut carbon fibre

end mill for carbon fiber

Carbon fiber surpasses conventional CNC machining materials such as aluminum, steel, wood, or glass. It creates high-performance, durable, and low-weight components. Machining carbon fiber sheets is generally accomplished using a router.

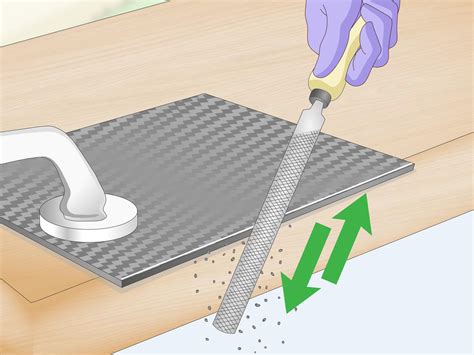

Machining carbon fiber presents several significant challenges, including tool wear and damage, delamination and fiber pullout, dust and health hazards, heat generation and thermal damage, and achieving a desired surface finish and precision.

FRP (fiber-reinforced plastic) composites are produced from strands of aramid, carbon, glass or other fibrous synthetics. These reinforcements are bound together using some resin, typically a thermoset or thermoplastic system. You can also use added ceramic or metal powders as reinforcements.

Carbon fibers are lightweight composites known for their high strength, low weight, durability, impact resistance, and many other beneficial properties for countless industrial applications. These composite parts are especially popular in . Machining carbon fiber promises superior-quality finished components characterized by lightness and rigidity. It allows you to craft unique carbon fiber constituents in line with your specific use requirements. We use Autodesk Fusion 360, configure the CAM settings, generate the G-Code, setup the Stepcraft router and then start the machining process. .more. Detailed video tutorial covering all the. Detailed tutorial explaining how to generate toolpaths using Autodesk Fusion 360, configure CAM setting and a desktop CNC router to make your own precision cut carbon fibre parts. This tutorial will assist those wishing to learn how to cnc carbon fibre.

The precision, accuracy, and efficiency of CNC machines make them invaluable tools in industries that rely on carbon fiber for high-performance applications. By investing in the right CNC machine, manufacturers can achieve clean and precise cuts, minimize .Machining Carbon Fiber Sheets - Cutting and drilling CFRP easily and precisly with a CNC milling machine. Make clean cutting edges and drill holes.

Carbon Fiber and Composites have special machining challenges. Discover the tips, techniques, and tooling needed for successful machining. Carbon fiber surpasses conventional CNC machining materials such as aluminum, steel, wood, or glass. It creates high-performance, durable, and low-weight components. Machining carbon fiber sheets is generally accomplished using a router.

Machining carbon fiber presents several significant challenges, including tool wear and damage, delamination and fiber pullout, dust and health hazards, heat generation and thermal damage, and achieving a desired surface finish and precision. FRP (fiber-reinforced plastic) composites are produced from strands of aramid, carbon, glass or other fibrous synthetics. These reinforcements are bound together using some resin, typically a thermoset or thermoplastic system. You can also use added ceramic or metal powders as reinforcements. Carbon fibers are lightweight composites known for their high strength, low weight, durability, impact resistance, and many other beneficial properties for countless industrial applications. These composite parts are especially popular in .

Machining carbon fiber promises superior-quality finished components characterized by lightness and rigidity. It allows you to craft unique carbon fiber constituents in line with your specific use requirements.

desktop cnc for carbon fiber

We use Autodesk Fusion 360, configure the CAM settings, generate the G-Code, setup the Stepcraft router and then start the machining process. .more. Detailed video tutorial covering all the. Detailed tutorial explaining how to generate toolpaths using Autodesk Fusion 360, configure CAM setting and a desktop CNC router to make your own precision cut carbon fibre parts. This tutorial will assist those wishing to learn how to cnc carbon fibre.The precision, accuracy, and efficiency of CNC machines make them invaluable tools in industries that rely on carbon fiber for high-performance applications. By investing in the right CNC machine, manufacturers can achieve clean and precise cuts, minimize .

cnc carbon fiber sheets

Tensile / yield strengths and ductilities for some of the plain carbon and low alloy .

cnc machine carbon fiber|desktop cnc for carbon fiber