advantages of sheet metal forming Metal forming processes offer numerous benefits regarding material efficiency, production rates, and mechanical properties, making them ideal for large-scale manufacturing. However, they come with challenges, such as high initial costs, material limitations, and the need for precise process control. I've discovered some surprising causes for water to taste this way, which extend beyond simply containing metal elements. Here’s what you need to know, plus ways to improve your drinking water quality and flavor.

0 · what is sheet metal forming

1 · steel sheet metal forming

2 · sheet metal manufacturing process

3 · sheet metal forming techniques

4 · sheet metal forming process

5 · sheet metal forming examples

6 · how does sheet metal form

7 · cons of sheet metal forming

Accessibility Statement - Washoe Metal Fabricating, Washoe Metal Fabricating

what is sheet metal forming

customized cnc lathe machining service

steel sheet metal forming

Advantages of Sheet Metal Forming. Despite the multitude of different processes available, many industries time and time again turn to sheet metal forming for their manufacturing needs. This versatile method is less . Advantages of Sheet Metal Forming. In sheet metal fabrication, sheet metal forming has several benefits. Here are some of the common . Advantages of Sheet Metal Forming. Despite the multitude of different processes available, many industries time and time again turn to sheet metal forming for their manufacturing needs. This versatile method is less expensive than some other manufacturing methods, like casting or forging.

Metal forming processes offer numerous benefits regarding material efficiency, production rates, and mechanical properties, making them ideal for large-scale manufacturing. However, they come with challenges, such as high initial costs, material limitations, and the need for precise process control. Advantages of Sheet Metal Forming. In sheet metal fabrication, sheet metal forming has several benefits. Here are some of the common benefits discussed below; Sheet metal forming is an economical process for large-scale production of parts than metal forging, and die casting processes. What Are the Benefits of Sheet Metal Forming? Unlike competing alternatives such as machining and casting, sheet fabrication allows the cost-effective, flexible, and rapid production of metal components.

Forming sheet metal is a highly cost-effective manufacturing process. It reduces waste and optimizes material usage, leading to significant cost savings on raw materials. The ability to mass-produce parts with consistent quality further enhances its economic advantages. Advantages of Sheet Metal Forming. Sheet metal forming offers several benefits that make it a popular choice in manufacturing: Versatility. Sheet metal forming is capable of producing a wide range of shapes and sizes. This flexibility allows manufacturers to create both simple and complex parts to meet diverse design requirements.

customized cnc turning drawing parts

Sheet metal forming is an extremely flexible process that exploits the strength and ductility of sheet metal to create long-lasting parts, which are more cost-effective compared to similar manufacturing processes like forging. How Does Sheet Metal Forming Work? Sheet metal forming, also known as precision sheet metal forming, is a crucial process in the manufacturing industry. It involves transforming flat metal sheets into desired shapes through mechanical and hydraulic processes such . Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. The completion of a product usually comprises of many steps – from cutting and bending to surface treatment and assembling. Often times a variety of fabrication techniques can be used to achieve a similar end result. Bending offers several advantages, including high design flexibility, cost-effectiveness, and the ability to create strong and durable parts. The process allows for the formation of both simple and complex shapes, making it suitable for a wide range of applications.

Advantages of Sheet Metal Forming. Despite the multitude of different processes available, many industries time and time again turn to sheet metal forming for their manufacturing needs. This versatile method is less expensive than some other manufacturing methods, like casting or forging. Metal forming processes offer numerous benefits regarding material efficiency, production rates, and mechanical properties, making them ideal for large-scale manufacturing. However, they come with challenges, such as high initial costs, material limitations, and the need for precise process control. Advantages of Sheet Metal Forming. In sheet metal fabrication, sheet metal forming has several benefits. Here are some of the common benefits discussed below; Sheet metal forming is an economical process for large-scale production of parts than metal forging, and die casting processes.

What Are the Benefits of Sheet Metal Forming? Unlike competing alternatives such as machining and casting, sheet fabrication allows the cost-effective, flexible, and rapid production of metal components.

Forming sheet metal is a highly cost-effective manufacturing process. It reduces waste and optimizes material usage, leading to significant cost savings on raw materials. The ability to mass-produce parts with consistent quality further enhances its economic advantages.

Advantages of Sheet Metal Forming. Sheet metal forming offers several benefits that make it a popular choice in manufacturing: Versatility. Sheet metal forming is capable of producing a wide range of shapes and sizes. This flexibility allows manufacturers to create both simple and complex parts to meet diverse design requirements.

Sheet metal forming is an extremely flexible process that exploits the strength and ductility of sheet metal to create long-lasting parts, which are more cost-effective compared to similar manufacturing processes like forging. How Does Sheet Metal Forming Work?

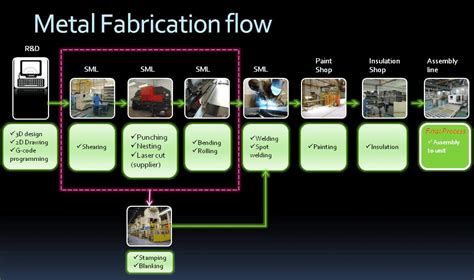

Sheet metal forming, also known as precision sheet metal forming, is a crucial process in the manufacturing industry. It involves transforming flat metal sheets into desired shapes through mechanical and hydraulic processes such . Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. The completion of a product usually comprises of many steps – from cutting and bending to surface treatment and assembling. Often times a variety of fabrication techniques can be used to achieve a similar end result.

All water heater electrical elements are rated by the amount of power they can emit. This power is described as wattage or watts. Displayed on the elements packaging is a number followed by the word "watts". A typical value for a 220 VAC hot water heater would be an element rating of 3500 watts.

advantages of sheet metal forming|sheet metal forming examples