electrical code box clearance When looking into electrical panel clearance safety, you need to start by looking at the requirements put in place by the national electric code, or NEC. The relevant section of the .

Learn from step-by-step solutions for over 34,000 ISBNs in Math, Science, Engineering, Business and more. Answers in a pinch from experts and subject enthusiasts all semester long. Welding and Metal Fabrication textbook solutions from Chegg, view all supported editions.

0 · osha electrical panel clearance

1 · nec and osha electrical clearance

2 · electrical panel clearance space

3 · electrical panel clearance regulations

4 · electrical panel clearance

5 · electrical clearance requirements

6 · electrical clearance distance chart

7 · building code electrical panel clearance

Each month the WELDING JOURNAL delivers news of the welding and metal fabricating industry. Stay informed on the latest products, trends, technology and events via in-depth articles, full-color photos and illustrations, and timely, cost-saving advice.

hiding junction box recessed track

osha electrical panel clearance

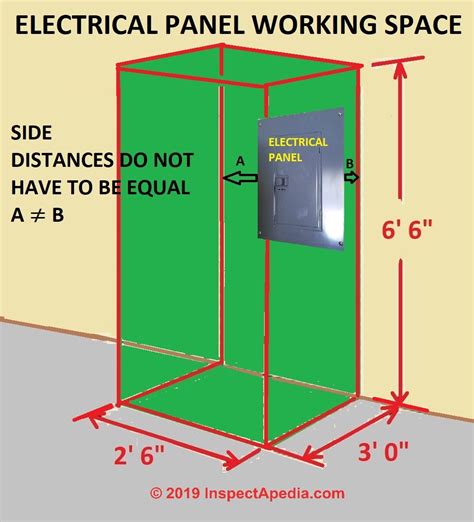

That is to say that "working space" around an electrical panel is synonymous with "clearance distances" around an electrical panel. See more[Click to enlarge any image] Summary: clear working space required in front, at sides and above an electrical panel include the following: 1. 6' 6" total height at the electrical panel 2. . See moreAccess and working space shall be provided and maintained about all electrical equipment to permit ready and safe operation and maintenance of such equipment. See more

nec and osha electrical clearance

(A) Accessibility Circuit breakers and switches containing fuses shall be readily accessible and installed so that the center of the grip of the operating handle of the switch or circuit breaker, when in its highest position, is not more than 2.0 m (6 ft 7 in.) above the . See more

The 2021 International Residential Code (IRC) requires electrical panels to have a clear working space to ensure safe operation and maintenance can be provided. When looking into electrical panel clearance safety, you need to start by looking at the requirements put in place by the national electric code, or NEC. The relevant section of the .

Clearance: Electrical panels must be installed in a readily accessible area with a minimum clearance of 30 inches (762 mm) wide, 3 ft (36 inches or 914 mm) deep, and 6.5 feet (≈ 2 . Front clearance: There should be a minimum of 3 feet of clearance at the front of all electrical equipment, including panelboards, switches, breakers, starters, transformers, etc. Note that all panel doors and access doors must be .

An electrical panel clearance refers to the minimum distance required between an electrical panel and any surrounding objects or surfaces. This clearance is mandated by safety regulations to prevent electrical hazards .OSHA and the National Electrical Code (NEC) specify that electrical panels must have a minimum clearance of 36 inches in depth, 30 inches in width, and 78 inches in height. These dimensions . Clearance Tables includes working space and clearance around indoor electrical panel, Circuit Board (NES 312.2), clearance for conductor entering In the United States, the National Electrical Code (NEC) is the primary standard that establishes the minimum clearance requirements for electrical panels. The Occupational Safety and Health Administration (OSHA) .

Insufficient clearance around electrical panels is one of the many electrical hazards that can endanger worker safety. Obstructed access to panelboards can prevent personnel from shutting down the source of power in the event of an .There is not a standard electrical code requirement that gives the minimum clearance distance between an electrical panel and a plumbing fixture, but you can figure a minimum distance from plumbing to panel by at least following the working space requirements.The 2021 International Residential Code (IRC) requires electrical panels to have a clear working space to ensure safe operation and maintenance can be provided. When looking into electrical panel clearance safety, you need to start by looking at the requirements put in place by the national electric code, or NEC. The relevant section of the national electric code here is NEC 110.26.

Clearance: Electrical panels must be installed in a readily accessible area with a minimum clearance of 30 inches (762 mm) wide, 3 ft (36 inches or 914 mm) deep, and 6.5 feet (≈ 2 meter) high in front of the panel.Front clearance: There should be a minimum of 3 feet of clearance at the front of all electrical equipment, including panelboards, switches, breakers, starters, transformers, etc. Note that all panel doors and access doors must be able to open a minimum of 90 degrees. An electrical panel clearance refers to the minimum distance required between an electrical panel and any surrounding objects or surfaces. This clearance is mandated by safety regulations to prevent electrical hazards such as electrocution, fire, or equipment damage.OSHA and the National Electrical Code (NEC) specify that electrical panels must have a minimum clearance of 36 inches in depth, 30 inches in width, and 78 inches in height. These dimensions ensure sufficient space for workers to safely and efficiently perform maintenance tasks.

Clearance Tables includes working space and clearance around indoor electrical panel, Circuit Board (NES 312.2), clearance for conductor entering

In the United States, the National Electrical Code (NEC) is the primary standard that establishes the minimum clearance requirements for electrical panels. The Occupational Safety and Health Administration (OSHA) also has regulations that apply to .Insufficient clearance around electrical panels is one of the many electrical hazards that can endanger worker safety. Obstructed access to panelboards can prevent personnel from shutting down the source of power in the event of an accident.

There is not a standard electrical code requirement that gives the minimum clearance distance between an electrical panel and a plumbing fixture, but you can figure a minimum distance from plumbing to panel by at least following the working space requirements.The 2021 International Residential Code (IRC) requires electrical panels to have a clear working space to ensure safe operation and maintenance can be provided. When looking into electrical panel clearance safety, you need to start by looking at the requirements put in place by the national electric code, or NEC. The relevant section of the national electric code here is NEC 110.26.Clearance: Electrical panels must be installed in a readily accessible area with a minimum clearance of 30 inches (762 mm) wide, 3 ft (36 inches or 914 mm) deep, and 6.5 feet (≈ 2 meter) high in front of the panel.

Front clearance: There should be a minimum of 3 feet of clearance at the front of all electrical equipment, including panelboards, switches, breakers, starters, transformers, etc. Note that all panel doors and access doors must be able to open a minimum of 90 degrees. An electrical panel clearance refers to the minimum distance required between an electrical panel and any surrounding objects or surfaces. This clearance is mandated by safety regulations to prevent electrical hazards such as electrocution, fire, or equipment damage.

electrical panel clearance space

OSHA and the National Electrical Code (NEC) specify that electrical panels must have a minimum clearance of 36 inches in depth, 30 inches in width, and 78 inches in height. These dimensions ensure sufficient space for workers to safely and efficiently perform maintenance tasks.

electrical panel clearance regulations

Clearance Tables includes working space and clearance around indoor electrical panel, Circuit Board (NES 312.2), clearance for conductor entering In the United States, the National Electrical Code (NEC) is the primary standard that establishes the minimum clearance requirements for electrical panels. The Occupational Safety and Health Administration (OSHA) also has regulations that apply to .

high performance sheet metal fabrication services

high precision cnc machining parts

S&B Metal Products provides Precision Metal Fabrication, Powder Coating, and Installation Services. With locations in Ohio and Florida, S&B fabricates custom, high-quality, precision metal products.

electrical code box clearance|electrical clearance requirements