sheet metal joints hems and seams When hemming is carried out in a way that a joint between two sheet metal parts is created, it is called seaming but more on that later. So, without further ado, let’s dive into the subject. Table of Contents hide. I What .

Create shimmering, three-dimensional effects with Tulip Metallic Fabric Puff Paint. This paint comes in an easy-squeeze bottle with a specially designed tip for optimal paint flow. Use it to embellish t-shirts, bags, and a variety of other fun fabrics.

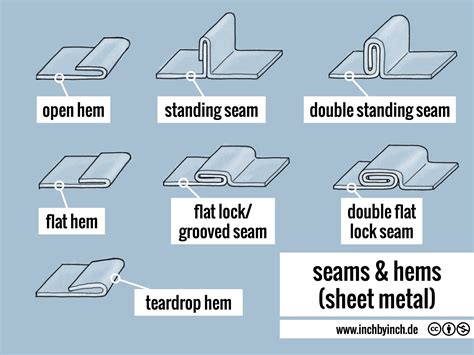

0 · types of sheet metal seams

1 · sheet metal side seam

2 · sheet metal seams pdf

3 · sheet metal seams explained

4 · sheet metal seams diagram

5 · sheet metal seam joints

6 · sheet metal corner joints

7 · grooved seam joints

$144.64

types of sheet metal seams

sheet metal fabrication albuquerque nm

Learn how sheet metal seams are made and used in the HVAC industry to fabricate air conditioning ductwork.Several types of seams used to join sheet-metal sections are discussed in this section. There are three types of lap seams: the PLAIN LAP seam, the OFFSET LAP seam, and the CORNER . This video discusses the different commonly used connection joints found on Sheet Metal Duct work. The four most common types of sheet metal hems used by Approved Sheet Metal are closed hem, teardrop hem, open hem, and rolled .

Sheet metal joints are found in every sheet metal assembly. Sheet metal fabrication techniques create these special joints to enable the proper function of t.

When hemming is carried out in a way that a joint between two sheet metal parts is created, it is called seaming but more on that later. So, without further ado, let’s dive into the subject. Table of Contents hide. I What .Sheet Metal Hemming Vs. Sheet Metal Seaming. The rolling over of a sheet metal edge onto itself is known as hemming in the metalworking industry. Hemming includes rolling the edge flush against itself instead of sewing, which joins the .Sheet metal joining operation is crucial part of the sheet metal fabrication process. Joint reliability depends on its type, sheet metal material, and manufacturing process. This article covers various types of sheet metal joining techniques, .Sheet metal hem is a fabrication process where the edge of sheet metal is folded over onto itself, creating a smooth, rounded finish that enhances the final product’s safety and aesthetic appeal. This post will take you through the .

Formed edges are formed from the sheet metal itself.* Yes, true. Lap seams are commonly used for roof flashing and gutters.* . Yes, true. A lap seam can be spot-welded.* Yes, true. Hems and edges are used mainly in architectural sheet-metal work and special projects. Yes, true. A spin collar is formed on a special rollforming machine .

A complete list of hemming benefits on a sheet metal product is as follows: Hems strengthen the sheet metal edge. They improve the surface appearance and surface quality. They hide defects such as rough edges and . Learn how sheet metal joints are made and used in the HVAC sheet metal industry to make air conditioning ductwork. . (#4) has a hem at each end. Hemmed S Slip Joint. Watch the video below to see how the Slip and .The SINGLE-HEM EDGE is shown in figure 2-54. This edge can be made in any width. In general, the heavier the metal, the wider the hem is made. . Multiply 1/8 by 2 1/2 and your answer will be 5/16 inch, which you will allow when laying out sheet metal for making the wire edge. Joints. . Figure 2-65.-Common sheet-metal seams.

sheet metal side seam

Multiply 1/8 by 2 1/2 and your answer will be 5/16 inch, which you will allow when laying out sheet metal for making the wire edge. Joints The GROOVED SEAM JOINT (fig. 2-57) is one of the most widely used methods for joining light- and medium-gauge sheet metal. It consists of two folded edges that are locked together with a HAND GROOVER (fig. 2 . In sheet metal operations, a hem or seam is a type of edge finishing that involves bending and folding the edge of a piece of sheet metal over itself to crea.Hems, Edges, and Seams Sheet metal pieces, such as ductwork, down spouts, and washing machine housings, begin with a flat pieces of metal. Patterns of the stretched out pieces are transferred or made directly on to the flat metal. These patterns include allowances, or additional material, for hems, seams, and edges. The amount of allowance is determined by the .Workshop notes for sheet metal joints and opertions. - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Sheet Metal Joints Sheet Metal Operations Lap joint Seam joint Locked seam joint Hem joint Wired edge joint Cup or circular joint Flanged joint Angular joint Cap joint

In sheet metal hemming means to fold the metal back on itself. . Even without sophisticated seaming machines a combination of two hems can create strong, tight joints with little or minimal fastening. Hems can even be used to strategically double the thickness of metal in areas of a part which may require extra support.

This document discusses various edges, joints, seams, and notches used in sheet metal work. It describes single and double hem edges, wire edges, grooved seam joints, cap strip seams, drive slip joints, 'S' joints, lap seams, grooved seams, Pittsburgh lock seams, standing seams, dovetail seams, and square, slant, and V notches. Here’s a look at the four most common types of sheet metal hems that we use: Table of Contents. 1; 2 When to apply the 4 Common Types of Sheet Metal Hems to your Design. 2.0.1 1. Closed hem. 2.0.2 2. Teardrop hem. 2.0.3 3. Open hem. 2.0.4 4. Rolled hem. 3 Sheet Metal Part Design for Manufacturing Tip.

Both hems and seams require careful measuring and sewing techniques to ensure they are even and secure. . A border made on sheet-metal ware by doubling over the edge of the sheet, to stiffen it and remove the sharp edge. . Hence, a line of junction; a joint; a suture, as on a ship, a floor, or other structure; the line of union, or joint .Hems and edges are used mainly in _____ sheet metal work and special projectsin this video i am explaining you aboutwhat is seam in sheet metaltypes of seam in sheet metalशीट मैटल शाप में कितने प्रकार के जोड़ . Sheet Metal // Ham // Seam // Notch // Grooved Seam // Lap Joint // 💥 #Operation_of_Sheet_MetalITI TECHNICAL ZONE प्रिय .

Study with Quizlet and memorize flashcards containing terms like Several methods can be used to join a seam., Formed edges are formed from the sheet metal itself., Lap seams are commonly used for roof flashing and gutters. and more.Install Work with laps, joints, and seams that will be permanently watertight and weatherproof. 1. Install exposed sheet metal Work that is without oil canning, buckling, and tool marks . and tool marks and that is true to line and levels indicated, with exposed edges folded back to form hems. Install sheet metal flashing and trim to fit .

Just do a "hem" in sheet metal mode and mess with your set backs, as Sniper1rfa suggests. OR, since you're already in sheet metal mode, just do a series of 90 degree bends. Be warned, Metal in real life acts a lot different than in the "perfect" world of solid works. #ductwork #hvac #sheetmetal #ventilationFolding or bending tabs is an economical way of making permanent sheet metal joints. We can do this process on sheet metal bending machines. Therefore it does not require an additional hardware setup. Tab joints have application in joining .1. Make a series of straight cuts about 1/2" apart and approximately 1/2" deep on the end of a round pipe 2. Bend every other tab out to form a shoulder on the outside of the flat sheet metal 3.Insert the pipe into the hole that has been cut for the pipe 4. Hammer over the remaining tabs to hold the pipe in place

They have the ability to close Pittsburgh lock up to a maximum thickness of 1.2mm mild steel on the SC12 models and a maximum of 1.0mm on the SC10 models, automatically adjusting in accordance to the sheet thickness. The seam closers/lockers are powered by a 1400 watt speed adjustable motor, enabling the user to achieve high quality and tightly .Explanation: Sheet Metal. Hems. A Hem is an edge or border made by folding.; Hem stiffens the sheet of metal and does away with the sharp edge.; It is a flange used to add strength to or relieve the sharpness of exposed edges or to connect separate edges or parts together at a seam.; Hemmed edges are necessary when an exposed edge of a pattern must be strengthened. These methods create strong, permanent joints, essential for parts that require closed hems or complex structural grooved seams. Laser welding, in particular, offers precision and strength, ideal for intricate sheet metal design. . Types of sheet metal joints include Folding/Tab Joints, Pulling Rivets, Self-clinching, Screw Joint/Fasteners .Seams, Joints, Grooves, Notches - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document provides an overview of tools and techniques for laying out and fabricating sheet metal ductwork. It describes common layout tools like scribes, squares, combination squares, and protractors that are used to accurately measure and mark sheet .

Sheet metal hem radius, there is only one 180-degree bend in a hem. Some hems are closed, which means that the inside bend radius is zero. . In contrast to seaming, which involves folding sheet metal while using a seam to link the two layers, hemming includes folding sheet metal so that the two layers are flush with one another. More Resources: 1 Common Weld Joints in Custom Sheet Metal Fabrication. 1.1 Open corner weld joint . Typically used on aluminum parts over 0.40” thick, open corner joints can be welded using several methods: fillet/seam, fuse, tack, or stitch welding. Our expert welders can determine the right approach based on the characteristics of the material and how .

Our engineers partner with precision manufacturers to plan, design, and integrate turnkey CNC machining solutions that maximize uptime, output, and quality.

sheet metal joints hems and seams|sheet metal seams diagram