cnc machine codes Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple. Make precision car parts on demand using CNC machining, sheet metal, 3D printing, and more. Get quotes in seconds and parts within days. Instantly access the production capacity of over 10,000 manufacturers with wide-ranging capabilities and certifications across 46 states and around the world. From your desktop.

0 · g code explained with examples

1 · g code commands cheat sheet

2 · g and m code cheat sheet

3 · cnc turning g code list

4 · cnc machine codes list

5 · cnc g code cheat sheet

6 · cnc g code chart

7 · cnc code list pdf

AHP offers a wide-range of high-quality competitively priced Vertical & Horizontal Machining Centers, CNC Lathes, Double Column Machining Center, Machine Tools & More

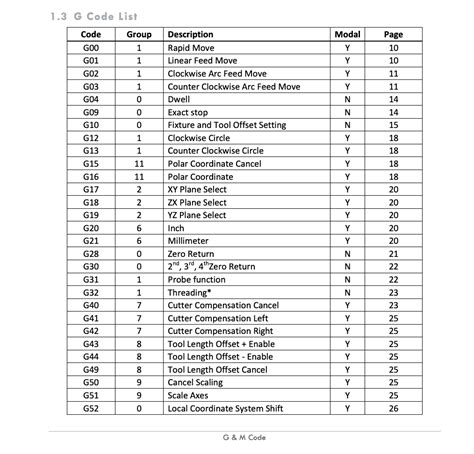

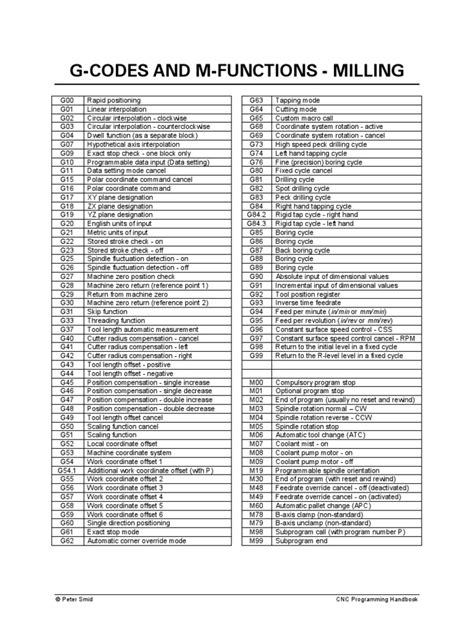

Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple. CNC G-codes & M Codes for milling and turning with explanations, . Our exploration will include codes that are pivotal for operations such as G00 for Rapid Positioning, G01 for Linear Interpolation, through to specific functionalities like G17 for XY Plane Selection, and system selections . Manufacturers all around the world use CNC programming to control a machine’s tools to produce parts. At the heart of this automated manufacturing process is a set of instructions that tells a CNC machine where .

Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the . In computer numerical control (CNC) machining, G-code is the essential language used for precise communication between an operator and a machine. This guide seeks to demystify G-code by providing a complete .

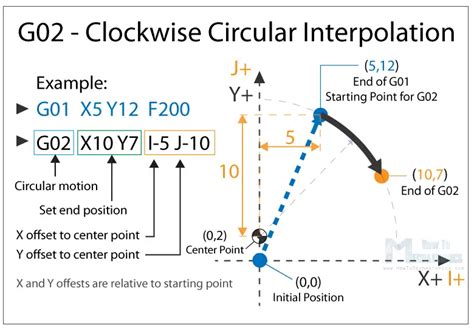

CNC machines work by following the commands or instructions (G-codes / M-codes) which are given in Part Program. Here are G-codes for Fanuc cnc control which are necessary for a. G-code is a CNC programming language that directs a CNC machine’s functions related to the cutting tool’s movement. It stands for ‘Geometric code.’. G-code guides the CNC machine’s actions by combining .

G-code is the primary programming language of CNC machines. It relates to the geographical coordinates of the machine arm so that it knows how and where to move. Without this code, your CNC machine would be a . Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)

Our exploration will include codes that are pivotal for operations such as G00 for Rapid Positioning, G01 for Linear Interpolation, through to specific functionalities like G17 for XY Plane Selection, and system selections with G20 and G21 for Inches and Millimeters, respectively.I explore a large list of CNC G Codes and look at both their function and uses on both CNC lathes and CNC milling machines Manufacturers all around the world use CNC programming to control a machine’s tools to produce parts. At the heart of this automated manufacturing process is a set of instructions that tells a CNC machine where – and how – .

Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the heart of modern manufacturing, allowing machines to transform raw . In computer numerical control (CNC) machining, G-code is the essential language used for precise communication between an operator and a machine. This guide seeks to demystify G-code by providing a complete overview of its structure, commands, and applications.

CNC machines work by following the commands or instructions (G-codes / M-codes) which are given in Part Program. Here are G-codes for Fanuc cnc control which are necessary for a.

G-code is a CNC programming language that directs a CNC machine’s functions related to the cutting tool’s movement. It stands for ‘Geometric code.’. G-code guides the CNC machine’s actions by combining instructions readable by the microcontroller. This simple programming language requires no intricate logic or mathematical skills. G-code is the primary programming language of CNC machines. It relates to the geographical coordinates of the machine arm so that it knows how and where to move. Without this code, your CNC machine would be a stationary device, such as a router or lathe. Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.

g code explained with examples

CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)

Our exploration will include codes that are pivotal for operations such as G00 for Rapid Positioning, G01 for Linear Interpolation, through to specific functionalities like G17 for XY Plane Selection, and system selections with G20 and G21 for Inches and Millimeters, respectively.I explore a large list of CNC G Codes and look at both their function and uses on both CNC lathes and CNC milling machines Manufacturers all around the world use CNC programming to control a machine’s tools to produce parts. At the heart of this automated manufacturing process is a set of instructions that tells a CNC machine where – and how – .

Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the heart of modern manufacturing, allowing machines to transform raw .

In computer numerical control (CNC) machining, G-code is the essential language used for precise communication between an operator and a machine. This guide seeks to demystify G-code by providing a complete overview of its structure, commands, and applications.CNC machines work by following the commands or instructions (G-codes / M-codes) which are given in Part Program. Here are G-codes for Fanuc cnc control which are necessary for a. G-code is a CNC programming language that directs a CNC machine’s functions related to the cutting tool’s movement. It stands for ‘Geometric code.’. G-code guides the CNC machine’s actions by combining instructions readable by the microcontroller. This simple programming language requires no intricate logic or mathematical skills.

g code commands cheat sheet

BXD has more than 10 years experiences in custom CNC machining parts manufacturing, we committed to providing you with the finest CNC machining services.

cnc machine codes|g and m code cheat sheet