standard sheet metal tolerances Actual tolerances in sheet metal fabrication are influenced by various factors, underscoring the necessity of engaging with your fabricator at the initial stages of design. . Bend Angles: The standard tolerance for bend . Operators use a computer numerical control (CNC) milling machine to cut and shape metal into components used in manufacturing. A CNC milling machine operator controls the automated .

0 · typical sheet metal tolerances

1 · steel plate thickness tolerance chart

2 · standard sheet metal tolerances chart

3 · stainless steel sheet tolerance chart

4 · sheet thickness tolerance chart

5 · sheet metal tolerances chart

6 · sheet metal thickness tolerance chart

7 · astm steel sheet tolerance chart

$60.63

Even though the term is used all the time, the reality of manufacturing tolerances can get quite complicated depending on the process . The first dimension, 11.20±0.25, has a tolerance equivalent to approximately ±.010 inches. This dimension alone is challenging – our standard tolerance sheet indicates that a .

1) All manufacturing tolerances used up to that point (such as laser-cutting tolerances, welding tolerances and more) 2) All bend tolerances for the entire part, added together We call this an uncontrolled dimensions because there .Tolerances: Sheet metal tolerances should not be tighter than necessary to make the part functional. Tight tolerances raise the cost of manufacturing significantly. Practical tolerances vary according to the design requirements. Tolerances of +/- .010 should be considered minimum. Linear tolerances should be held as loose as possible. Actual tolerances in sheet metal fabrication are influenced by various factors, underscoring the necessity of engaging with your fabricator at the initial stages of design. . Bend Angles: The standard tolerance for bend .

Discover the essentials of Sheet Metal Tolerances with our in-depth guide covering dimensional, geometric, and material variations. . (DIN), particularly DIN 6930, is used for stamped metal parts. This standard specifies the tolerances of metal stamping. These standards are not just guidelines. They are essential to ensure our products .In sheet metal design, I would not be designing where I would require 15mil tolerance for anything to line up correctly. That's why god invented slotted holes. . I'm used to +/-.030" as the standard tolerance for bent sheet metal parts without really thinking about it. Tighter can be achieved, so +/-.015" seems reasonable if that's what you .

I found some standard flatness tolerances on stock sheet metal but I can't find anything on pieces which have been modified and cut. I assumed there would be standard flatness tolerances somewhere of modified sheet metal. I will have a chat with the suppliers to ask for advice and what processes they have to potentially flatten the metal.

For example, the manufacturer recommends ISO 2768-mk for sheet metal parts and ISO 2768-fh for machined components. In the above example, “m” and “k” have defined the tolerance class. You can calculate the critical dimension tolerance using tolerance stack-up analysis. You can also use a tolerance stack-up calculator for this purpose.This International Standard applies to dimensional and shape tolerances for all cold-rolled steel sheet products. Note Cold-rolled steel strip is not covered by this International Standard. 2 Dimensional tolerances Dimensional tolerances are given in Tables 1 to 8. Table 1 — Thickness tolerances for coils and cut lengths

typical sheet metal tolerances

electrical metal box manufacturers in indore

utilizing “soft tooling” or standard tooling, turrets lend themselves to both the highly flexible production of prototypes and inexpensive production quantities. Tolerances – The feature to feature tolerance for the turret press is +/-.004”, the punched hole tolerance is +/-.002”.General Tolerances ISO 2768-1 ISO 2768-1 is intended to simplify drawing indications and specifies general tolerances in 4 tolerance classes (f – fine, m – medium, c – coarse, v – very coarse). . CNC Machining, Vacuum Casting, Injection Molding, Sheet Metal Fabrication. Table 6 - General Tolerances on Symmetry Table 7 - General .

“Having a handy guide to compare your called tolerances will profoundly affect your production,” Benson explained. By a “handy guide,” Benson means a guideline specifying reasonable tolerances for a formed part, both for linear and angular dimensions, as shown in Figure 1.. “You will no longer be making unreasonable demands, and no longer will you have .The sheet metal does however have a tolerance on the rolling thickness which needs to be taken into account when designing a tight fitting assembly, especially as the sheet metal material gets thicker. . The sheet metal data table below covers all the standard alloy grades of aluminium. Group I = 1000 series, 3000 series, 4006, 4007, 5005 .It applies to the dimensions of parts that are produced by metal removal or parts that are formed from sheet metal. NOTES 2 These tolerances may be suitable for use with materials other than metal. 3 Parallel International Standards exist or are planned, e.g. see IS0 60621) for castings.

TOLERANCE STANDARD FOR SHEET METAL FEATURES. K.P.M. Apr 17, 2023; Drafting Standards, GD&T & Tolerance Analysis; Replies 4 Views 58. Apr 20, 2023. supergee. Locked; Question; angular tolerance in ISO 2768-1 for sheet metal process 1. kokerkov; Jan 11, 2024; Drafting Standards, GD&T & Tolerance Analysis; Replies 5 Views 81. The main thing to be considered for selection of sheet metal tolerance is not just the Linear dimension as like IS 2102, the Reference from where to where the dimension take plays a vital role. Table 3.1 shown the .

electrical lockout box

Remember, these are standard tolerances. In many cases, we can tighten these up, but there's usually a cost. So, if you run into a situation where you need tighter tolerances to make your project work - please let us know. At that time, we will try to find cost-effective options for you. When working with Protocase, please keep in mind:Hardware insertion and riveting: Standard PEM sheet metal hardware; Powder coating: A variety of powder coat paint colors available in textured and non-textured finish, . Offsets are used to create Z-shaped profiles in sheet metal . This document also provides methods for specifying thickness tolerances. Return to Homepage. SAE International site SAE MobilityRxiv SAE Mobilus SAE OnQue SAE StandardsWorks. About. Contact. Legal & Policies. . Standard Sheet Steel Thickness and Tolerances J1058_201504 Sheet metal tolerances describe the allowable variations in shape, size, and geometry for sheet metal fabrication. Metal tolerancing impacts project outcomes in multiple ways, including fit, functionality, manufacturing costs, and performance. . Special tolerances are non-standard, customized, and specific to the design. They deviate from the .

Comprehensive resource of fabrication tolerances and dimensional variation guidelines for sheet metal manufacturing and fabrication. Transform your team's workflow with Protocase Designer Enterprise, . Standard Tolerances For Copper. Usually, choosing material thickness is one of the first steps a designer takes when starting a project. We .Selecting Precision Parts Processing. UV laser machines work cleanly to achieve precise cuts. As industries are demanding smaller and smaller parts, the demand for processes that can achieve tight tolerance is only increasing, and UV lasers are perfectly positioned to meet this need.. When it comes to precision laser cutting quality, precision parts need to pass both visual inspections .

As noted above, [±].015" is what sheet metal shops can do, cheaply. If you place [±].015" and [±].030" tolerances all over your drawing and one additional dimension at [±].010", the shop knows which dimension is critical and difficult. Your reasonable tolerances everywhere else shows that you are serious about the tight one. Master sheet metal tolerances with our guide. Explore key factors, material properties, and best practices for precision fabrication. . ISO 2768 is an important standard for general tolerances in sheet metal fabrication. It specifies tolerance classes for linear dimensions, angular dimensions (ISO 2768-1) and geometrical tolerances (ISO 2768 . This blog discusses in over view of How to select sheet metal Tolerance as per standard. How to select welding Tolerance as per standard. How to select General Tolerance as per standard. Wednesday, April 10, 2013. sheet metal .

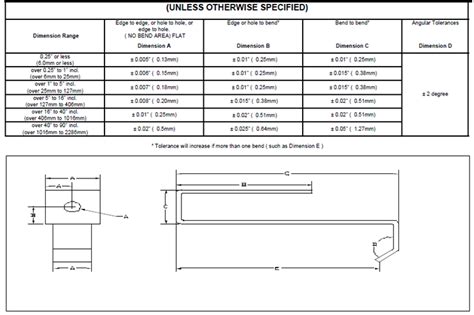

Edge to edge, or hole to hole, or Edge or hole to bend* Bend to bend* Angular Tolerances edge to hole. ( NO BEND AREA) FLAT 0.25" or less (6.0mm or less) This whitepaper helps describe a set of broad guidelines that you can use while specifying tolerances for your sheet metal parts drawing(s). Essentially, these are in place due to practical limitations of sheet metal forming, shearing and punching. . The process is usually carried out with tools of standard shapes and sizes, such as circles . As raw material, sheet metal has behavioral weirdness. Some of that weirdness, stress in particular, is relieved during manufacturing. The resulting bend angle variation, and sometimes the required adjustment to the flat layout, contributes to the reason that machined parts (typical tolerance of ±0.002 in.) can routinely have tighter .

steel plate thickness tolerance chart

electrical metal box enclosures

Find Wood wall mounted shelving at Lowe's today. Shop wall mounted shelving and a variety of storage & organization products online at Lowes.com.

standard sheet metal tolerances|sheet thickness tolerance chart