sheet metal seams There are five common types of sheet metal joints that are extremely common across the industry, all with varying uses and advantages. Sand the weld flat with a metal angle grinder or Dremel tool. Try using an angle grinder fit with an abrasive flap wheel, for instance. Wait at least 30 seconds for the weld to finish cooling, then hold the wheel up to each spot.

0 · welding holes in sheet metal

1 · types of sheet metal seams

2 · sheet metal seams pdf

3 · sheet metal joints and seams

4 · seaming process in sheet metal

5 · interlocking sheet metal joints

6 · interlocking sheet metal design

7 · grooved seam sheet metal

But, in the case of 316L stainless, you will need to incorporate a 316L wire. For these types of materials, a tri-gas mixture is recommended, which consists of 90% helium, 8% argon and 2% CO2. Finally, if you are welding sheet metal with solid wires, an electrode positive one is recommended or one with reverse polarity.

When ducts get too wide they could require an additional seam to add strength and span the greater distances. The use of a standing seam provides strengthening for the larger ducts. Depending on the size of the duct, the standing seam will extend upward either by 1 inch or 1-1/2 inches. See moreThe Pittsburgh seam is used for pressure classes and duct sizes larger than the Snap Lock seam can handle. The Pittsburgh seam comes in small and large sizes depending on . See moreFor duct systems requiring a heavier duty seam as can be found in some lab exhaust systems, the seam can be fully welded longitudinally. A . See moreAs shown below the metal is slipped into the roller and then it’s rotated around the three rollers. To make a greater or small circumference you adjust the position of the back roller. Now . See more

welding holes in sheet metal

types of sheet metal seams

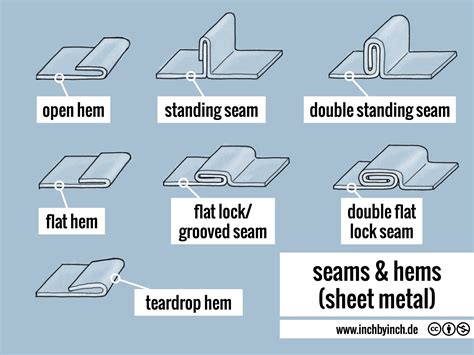

There are five common types of sheet metal joints that are extremely common across the industry, all with varying uses and advantages.Several types of seams used to join sheet-metal sections are discussed in this section. There are three types of lap seams: the PLAIN LAP seam, the OFFSET LAP seam, and the CORNER . Learn how sheet metal joints are made and used in the HVAC sheet metal industry to make air conditioning ductwork.

Sheet metal joints are found in every sheet metal assembly. Sheet metal fabrication techniques create these special joints to enable the proper function of t.

The main methods of sheet metal joining include welding, riveting, threaded connections, and adhesion. Welding is one of the most common and crucial methods in sheet metal joining. It achieves a durable connection by . This video discusses the different commonly used connection joints found on Sheet Metal Duct work. The seam is formed by folding the edges of the metal sheets, creating a tight and secure connection. One of the key features of a Pittsburgh seam is its overlapping design. When making a Pittsburgh seam, one edge of .

sealed tub with metal top box

sheet metal seams pdf

screws not going into junction box

OK , I know this has been hashed to death BUT, my other 57 Chevy pickup cab was chemically stripped before I got it and primed. I have been working on this cab for several years off and on and wanting to swap it out with the cab on my pickup now , but over the years where all the body panels are spot welded together the rust is coming back and pushing the layers of .Suitable for standing seam and round seam - penetration-free and fixed with sheet metal seam clamps. Systems References. K2 SingleRail System. Suitable for various load cases and many spans, including an extensive range of rails. More . K2 SolidRail System. The only seams are found at corner miters and downspouts. Seamless gutters are considered more durable because the seams of sectional gutters can weaken over 10 or 15 years down the road. . You’ll need gutter sealant for sealing the joints, sheet-metal screws to connect the downspout sections, and downspout bands to fasten against the house .evaluate 1/2 inch wide flat lock seam soldered joints. The industry’s current recommended widths are 5/8 inchwide flat lock seams (Architectural Sheet Metal Manual bySMACNA) and 3/4 inch wide flat lock seams (Copper and Common Sense byRevere Copper).

Seam welding, or fillet welding, is one of the most common methods we use at Approved Sheet Metal. This arc welding method uses a filler rod to create a continuous weld across the entire seam of the pieces being joined.

Hand Seamers Sheet Metal Tools,10 Inch-High Carbon Steel Sheet Metal Crimper Locking Plier Tools, Sheet Metal Clamp Duckbill Pliers, Hand Seamer Adjustable Wear Resistant Flat Head Vise Functional. 4.6 out of 5 stars. 7. .99 $ 21. 99. 8% off .Sheet metal, metal roofing and standing seam seaming tools for industry professionals. Quality Tools. Expert Training. Currency: USD . CAD USD Cart-0 item(s) hemming process A closed hem A seam. Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Hemming is the process in which the edge is rolled flush to itself, while a seam joins the edges of two materials. [1]Hems are commonly used to reinforce an edge, hide burrs and rough edges, and improve appearance..00 Subtotal. Shipping. Spiral seams on the other hand require no sealing and this is recognized by ASHRAE Standard 90.1. Our AMCA testing proves out the ASHRAE standard regarding spiral seams. The testing shows leakage rates so low as to be inconsequential. . Eastern Sheet Metal can fill all of your spiral duct and fitting requirements..00 Total. Checkout (484) 256-2729 Sign in. Tools .Historically, an important use of sheet metal was in plate armor worn by cavalry, and sheet metal continues to have many decorative uses, including in harnesses. Sheet metal workers are also known as “tin beaters” (or “tin knockers”), a name derived from the hammering of sheet metal seams when installing sheet metal roofing.

Series B1300 Mechanical locked standing seam panels . B&B Sheet Metal’s Series B1301/B1300 presents the same architectural aesthetics as the architectural snap-lockpanels except with structural strength and weather tightness advantage of a mechanically seamed system. The A1301/A1300 panel system serves the architectural needs of roofing . Chapter #2 – Sheet Metal Materials; Chapter #3 – Sheet Metal Coil Line; Chapter #4 – Plasma Cutting Table; Chapter #5 – Spiral Machine; Chapter #6 – Sheet Metal Seams; Chapter #7 – Sheet Metal Joints; Chapter #8 – Sheet Metal Casings and Plenums; Chapter #9 – Sheet Metal Shop Fabrication Productivity The industry’s current recommended widths are 5/8-inch-wide flat lock seams (Architectural Sheet Metal Manual by SMACNA) and 3/4-inch-wide flat lock seams (Copper and Common Sense by Revere Copper). Read More. .

sheet metal joints and seams

Sheet metal joints are connections or seams formed by joining two or more sheets of metal to create a unified structure or component. From riveting and welding to folding and soldering, sheet metal joints offer an array of .

I have done both,,the only time I will lap weld if everything has been sandblasted and is clean sheet metal,,of course it's always best to have clean sheet metal whether you lap or butt weld. . If you can't get at the seam on the inside later to clean it, just oil it after the car is painted. tedley, Feb 2, 2013. SHARE POST #24. Joined: Jan 3 .

Flat seamed roofs are used on very low-pitched roofs and have soldered seams. In this application, galvanized steel and copper are the most widely used metals, with stainless steel and zinc rarely installed. . Sheridan Sheet Metal Co. 4108 Quebec Ave N. New Hope, MN 55427. P: (763) 537-3686 F: (763) 537-8139. [email protected] .

Rebars can be cut and bended to different shapes used in various structures. Our rebar shapes in accordance with BS4466 1998, BS8666 2000, BS8666 2005. How to do a Groove Seam using a Pittsburg Machine, as well as how to cut sheet metal using a guillotine. The is a basic sheet metal task. Hemming is a sheet metal forming process where the edge is folded onto itself. Hems make a part more durable and improve its appearance. . A seam is used to connect two metal parts by interlocking the edges of the folded sheet metal parts. The resulting shape may even form a seal that isolates one side of the sheets from the other.

2 METAL ROOF DESCRIPTION The systems were constructed as follows: (see diagrams) Test Specimen 6 ft by 19 ft 5 inches Roof Pitch 4/12 Seam Height 1 inch standing; 1 1/2 inch batten Pan Width 20.75 inches at center, 15.25 at rakes Seaming double lock standing seam or batten seam conforming to SMACNA's Architectural Sheet Metal ManualOn the ribbon, click Sheet Metal tab Modify panel Corner Seam. Select a model edge on each of two adjacent sheet metal faces. Accept the default seam type or select another of the three seam types. In the Corner Seam dialog box, you can: Use the Face/Edge distance measurement method instead of the defaulted Maximum Gap Distance method.

This study tests the use of 1/2 inch wide flat lock seam soldered joints. The industry’s current recommended widths are 5/8-inch-wide flat lock seams (Architectural Sheet Metal Manual by SMACNA) and 3/4-inch-wide flat lock seams (Copper and Common Sense by Revere Copper).

scrollwork metal brackets

Typical installation details require that side laps of the roof panels are screwed together with sheet metal “stitching” screws. If snow, ice, or water accumulates, the only defense the lap seams have against water intrusion is the height of the seam above the roof surface. . While I completely agree with this statement, it applies most . 3M Bare-Metal Seam Sealer . Forms a durable seal to overlapping sheet metal with no shrinkage, cracking or outgassing – and lets you apply it efficiently and cost effectively. The heavy bodied sealer is formulated specifically to adhere consistently to properly prepared bare metal, such as steel or aluminum enclosures, in collision repair.

Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Hemming is the process in which the edge is rolled flush to itself, while a seam joins the edges of two materials. 1. Hemming Straight Hem.(Image source) (Image source) Contour hemming.(Image source) Hem detail.(Image source) Types of Hemming.(Image .

Learn why MIG, pulsed MIG, TIG and pulsed TIG are the ideal choices when welding sheet metal. When welding thin metal, the main objective is to avoid warping, burn-through and excessive heat-affected zones while still ensuring the weld has enough mechanical strength for the application.

sheet metal seams|grooved seam sheet metal