junction box screw hole too big One of the screw holes on a junction box on my ceiling has fallen apart, leaving a hole that is too big to fix a screw into (see top of picture). As a result, I cannot hang my smoke detector from the junction box, since the detector hangs from the heads of the screws. Learn about a junction box as it pertains to a residential home and its electrical wiring, plus DIY tips to install an electrical junction box.

0 · plastic junction box repair

1 · oversized screw hole repair

2 · mounting hole on electrical box

3 · junction box screw hole repair

4 · junction box replacement

5 · how to fix a screw hole

6 · electrical outlet screw hole

7 · broken junction box repair

These online courses are designed to provide the basic knowledge necessary to get started as a CNC machine operator or CNC machinist. They offer an introduction to basic CNC machine operation, proper machine safety, and fundamental machining processes.

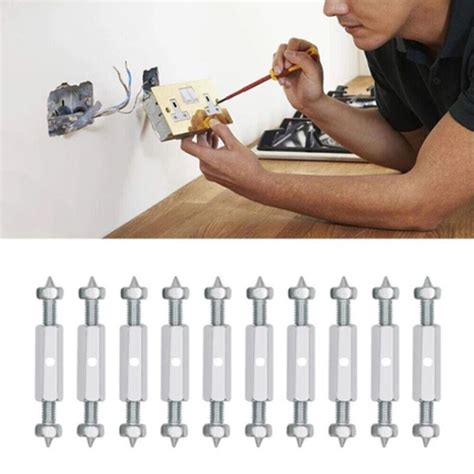

plastic junction box repair

One of the screw holes on a junction box on my ceiling has fallen apart, leaving a hole that is too big to fix a screw into (see top of picture). As a result, I cannot hang my smoke detector from the junction box, since the detector hangs from the heads of the screws.Given that the box is plastic, you have at least 3 options: Try a slightly larger .Loosen the screws that hold it to the box so it hangs below the box enough for the .

Given that the box is plastic, you have at least 3 options: Try a slightly larger screw. Fill the mounting hole(s) in the box with epoxy, drill a new . Loosen the screws that hold it to the box so it hangs below the box enough for the other screws to be usable. It may take some fiddling with fixture screws to find just the right setting. It is a little tricky to get the screws and .

steel curry boxes

How to Fix a Screwy Electrical Box. I recently had to deal with a loose receptacle inside a plastic electrical box. It turned out the screw holes in the box were stripped. To fix the problem, I slipped small zip ties into the stripped .The electrical box repair or replacement procedures described in this article series describes step by step repairs for both metal and plastic electrical boxes used in building electrical wiring systems. How to replace a loose, falling or .

I suspect this was caused by someone trying to overcome a too-crowded (or poorly laid out) junction box by using these screws to force the receptacle into the box. What is . That is not a junction box. It is a pot light fixture. You cannot use it as a junction box. You need to remove it, patch the hole and install a proper junction box. If a junction box is too big for a light fixture, it means that the junction box is physically larger than the light fixture and is not able to properly support it. This can be a problem because the light fixture will not be securely .

Exterior boxes should be attached with screws; the back of the box should have small holes for that purpose. If you have a metal box, use a screwdriver as a lever to remove the knockouts (the precut metal discs on .Too bad its not actually being bonded since its a plastic cover. But no they cant be #6's cause most round boxes especially weather proofs come with the #8-32s or 10-32/24 whatever and the holes are too big. I just wanted to clarify so .The screws that attach the fixture to the mounting bracket directly overlap with the holes in the junction. Pictures included. . the screws from the mounting bracket to be horizontal but that's where the holes are to attach the bracket to the .The ground screw and hole is "self tapping", meaning the hole isnt threaded, but that wont matter to the screw. Its gonna take a bit of muscle to get it going, but once you got it in a few threads it gets easier. But as long as you secure the .

Sheetrocker cut the hole too big on an old work box opening, and the tabs aren't catching. Any neat tricks or "gadgets" to fix this issue - short of cutting out the rock and patching in a new piece with a proper sized cut out? . sink a sheetrock screw into it through the sheetrock a few inches from each side of the box, then patch the oops .

Patch the old hole with a self-sticking drywall patch, then mount a new box to the joist about 8" further away from the wall. There are boxes that can be screwed right into the joist from below the ceiling (look for Madison Electric Products Fan and Fixture 1-Gang Gray Polycarbonate New Work/Old Work Standard Ceiling Fan Ceiling Electrical Box). We cut the holes in the drywall for the electrical outlet boxes too big and now the wings on the old-construction boxes can't clamp the wall. . Just make sure the hole is not so big it can't be covered by the finish cover. Share. Improve this answer. . Plastic screw from inside outlet box to stud. 0. Cut too big a hole in drywall for socket.If me, I'd clean it all out as much as possible and fill the screw holes and surrounding areas with 2-part epoxy. Then drill new holes. You can buy switch & outlet spacers at the big box in the electrical section (there's even a picture of this exact scenario). These are stackable spacers that go behind the tabs and the mounting screw goes through them. Sometimes, when working on receptacles I run into stripped screw holes. These holes are built-in to the junction box which is made of plastic or some brownish and brittle material. I suspect this was caused by someone trying to overcome a too-crowded (or poorly laid out) junction box by using these screws to force the receptacle into the box.

When I went to screw the bracket into the ceiling fixture box, it looks like the box's holes are too big. Not only do the screws slide right through the hole, but bigger screws won't fit through the bracket holes. Here is a picture of the box. Here is a picture of the screw that is supposed to go into the box. You can't tell, but it's way too .You need to attach the light somehow. I don't see threads in the inner holes so you will have to find the right size sheet-metal screws there - too big and you hear a nice popping sound, then you really will have to get at the bolts on top of the box. The bolts are no longer than a standard pancake box - are you sure you are aligning it properly? The “Too Big Junction Box” If You Want Small Sconces Or Ceiling Lights. Here’s the deal – a junction box is the electrical housing that sits behind the drywall that you connect a wall or ceiling light to, and most are a standard size (usually 4″, sometimes 5″, I guess), creating a hole that size in the wall.

Now, the hole in the wall is too long, so the clips won't grip (or rather, only one clip will grip where the other one would be too far from the drywall edge). . Once in you rotate it into place and then mount with drywall screws going through drywall and into the wood. If this area is exposed wall (not covered by a picture, a TV, or other .In most cases it isn't that the box is too narrow, it's that a cover was installed to narrow it on original installation. In other words the 4 inch box is covered by something like a TP331 narrowing it to 2.5 inches. If it is, just drill access holes perpendicular to the existing mounting holes, and mount to those newly exposed screw terminals.

oversized screw hole repair

mounting hole on electrical box

If the latter are you saying that the boxes no longer clamp to the drywall because the rectangular openings in the drywall are too large for the flanges or tabs to grip? Or are you saying that the boxes are solid but are recessed behind the surface of the drywall so the receptacle is loose when it is attached to the cover plate? –

When I did that it made the hole too big and now they sit loose. In hindsight, the anchors are threaded so they are probably the screw in kind. . Replaced kitchen outlets with GFCI; tile backsplash now blocks the receptacle from inserting . I wonder how I can connect some PCB (consider it as a plate where I drill holes) in to the holes from the enclosure (the 6 smaller holes in the bottom, where you can see 5 in the picture). The holes do not have any screw thread. .Either the junction box is too small or the metal plate is too large. I'm thinking I could just use a drywall anchor to attach the other end of the hinged metal plate. However, it still wouldn't be 100% flush with the ceiling because the grounding screw on the top side of the plate is making contact with the rim of the junction box (rather than .Looks like there’s only 2 wires coming in, which makes for replacing the box quite a bit easier, if you have attic access it would make it a breeze, if not carefully smash out the old box trying not to damage drywall too much, cut the mounting tabs off your new box, slide the wires in and wiggle it into place, put a couple screws through the side of it into the joist, and you’re done.

To install your universal bracket, dry-fit the bracket up to the junction box, and find the holes that work with your screw holes. You can use a pencil to mark around the bracket to know where to place it once you have it. Next, you will attach the bracket using your template marks, screwing the screws into the junction box.Well if you can spin that screw out from the backside be awesome. Worse case I’d probably drill and tap a 6/32 screw hole off to one side. Most guys around here would just throw a self tapping screw and call it a day but the sharp edge inside isn’t the “right way”, but drilling and tapping off the side isn’t the right way either.

I have the same situation; my fixture actually came with its own special bracket that allows the canopy to be screwed in from the sides. We also wanted to put a ceiling rose over the ratty hole in the drywall, so between the height of the rose and the setback of the box, the bracket needed to come out by 1/2" so the canopy could fit over the screwholes. Does most Heath-Zenith motion sensor lights share the same size of junction box? I tried to read their installation guide manual PDF files (for SL4150 decorative wall-mounted model and the typical garage motion sensor light like SL-5412). They look like using the same size of junction box but from the manual I can't really tell. Thanks!

Even if you don't want to follow the unterminated Cat5 route that Qualeboy mentioned, you don't need a huge hole for this. I have three cameras each mounted next to a junction box hidding the pigtail cables and connectors, so I drilled in the wall a hole wide enough to pass a RJ45 connector and Cat5 cable from the junction box to the house. Drywall hole slightly too large for mounting bracket to cover. Ask Question Asked 7 . instead of over top of it. The new one comes with a mounting bracket, but the screw holes for the bracket don't quite clear the hole from the old one. . It almost looks like in this case the flange could have one screw right into the junction box, and the .

Try a 4" square to round device ring. The thing you want is a 4", square to round device (mud) ring. A flat one (say a Garvin 52C3-F, or equivalent) would be preferable for this situation, but one with a small depth (say 1/2") would be manageable still if you can't find a flat one, even though you should be able to find the flat version at your local electrical supply house.The spring has the hole in the center, no adjustment can be made there. If you need you screw holes cheated up or down you are SoL with the spring. But with the screw design you have room to get the screw hole higher or lower than the exact middle of the hole in the wall.

However, the ground wire coming in should be connected first to the steel box, which it's not. There should be a small threaded hole which takes a 10-32 machine screw in the box already, or you can buy self-tapping grounding screws if you have an odd box without a pre-threaded hole. Yes, you can poke holes in the plaster for the mounting pins .

steel cutout box

Metal coining is a forging process by which very fine and intricate details can be created on the surface of a work piece. Coining may be used to control surface quality and detail on parts. Metal coining is often a finishing process for manufactured products.

junction box screw hole too big|how to fix a screw hole