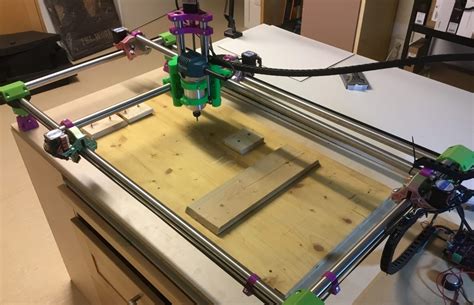

build cnc router machine Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, .

Get everything fitted well, using self-tapping sheet metal screws to hold the new panel in place while you trim and fit. The self-tappers are great because you can remove the pan to trim it multiple times, and put it back in the same place during fitting.

0 · make your own cnc machine

1 · homemade cnc router plans

2 · homemade cnc router machine

3 · cnc homemade router

4 · building your own cnc

5 · build your own cnc router

6 · build your own cnc kit

7 · best cnc router for beginners

Corner construction plays a vital role in ensuring the durability and strength of sheet metal parts. When corners are not properly prepared for welding, it can lead to parts being out of tolerance, weak, and susceptible to breakage.

snap on plastic box with steel drawers

When designing a CNC router it is helpful to ask yourself a couple of questions. Here you will find the design process I went through for my CNC router. What type of CNC router do you want to .This instructable will show you how to construct a CNC Router that will allow .

DIY CNC Router Build (large Format 5x10ft, Rack and Pinion): This is a not so little . A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.This instructable will show you how to construct a CNC Router that will allow you to cut 3-D shapes out of wood, plastic and aluminum using a standard hand .Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, .

snake river sheet metal

While commercially available CNC router machines can be expensive, building your own DIY CNC router can be a cost-effective alternative for hobbyists and small-scale manufacturers. In .A DIY CNC router (Computer Numerical Control) is a versatile tool that allows hobbyists, makers, and small businesses to build precise cuts, engravings, and 3D carvings. Unlike traditional handheld routers, CNC routers are automated . A CNC machine with an expansive 30x30" work area, supporing a router, laser, simple plotting and work monitoring camera. Control includes a tethered control box, game . A compact router, baltic birch plywood, some basic hardware, and an off-the-shelf electronics kit are all you need to build your own computer-controlled router. This project is ideal for tech-savvy woodworkers looking to .

Learn the basics and follow my process to come up with your own CNC router design that meets your goals and budget. Follow my carefully engineered plans to build this high performing, affordable CNC router. Full set of detailed drawings, .When designing a CNC router it is helpful to ask yourself a couple of questions. Here you will find the design process I went through for my CNC router. What type of CNC router do you want to build? There basically are two types of CNC routers: .

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.This instructable will show you how to construct a CNC Router that will allow you to cut 3-D shapes out of wood, plastic and aluminum using a standard hand held router. Recently I have noticed that more and more projects on instructables have involved the use of some sort of CNC machine, be it a laser cutter, 3d printer, milling machine, etc.Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. ThisDIY CNC Router Build (large Format 5x10ft, Rack and Pinion): This is a not so little summary of the build of my homemade CNC router, aka The Overpass. This instructable is more of a documentation of how I built my CNC and is not to be mistaken as a tutorial for buidling a CNC.

While commercially available CNC router machines can be expensive, building your own DIY CNC router can be a cost-effective alternative for hobbyists and small-scale manufacturers. In this comprehensive guide, we will explore the step-by-step process of creating a .A DIY CNC router (Computer Numerical Control) is a versatile tool that allows hobbyists, makers, and small businesses to build precise cuts, engravings, and 3D carvings. Unlike traditional handheld routers, CNC routers are automated and follow digital designs.

A CNC machine with an expansive 30x30" work area, supporing a router, laser, simple plotting and work monitoring camera. Control includes a tethered control box, game controller style jog control, and relay controlled AC outlets for all appliances.

A compact router, baltic birch plywood, some basic hardware, and an off-the-shelf electronics kit are all you need to build your own computer-controlled router. This project is ideal for tech-savvy woodworkers looking to add a CNC router to their shop or beginners who want to give this type of woodworking technology a try.Learn the basics and follow my process to come up with your own CNC router design that meets your goals and budget. Follow my carefully engineered plans to build this high performing, affordable CNC router. Full set of detailed drawings, instructions, and Bill of Materials. Fastest path to ownership.When designing a CNC router it is helpful to ask yourself a couple of questions. Here you will find the design process I went through for my CNC router. What type of CNC router do you want to build? There basically are two types of CNC routers: . A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.

This instructable will show you how to construct a CNC Router that will allow you to cut 3-D shapes out of wood, plastic and aluminum using a standard hand held router. Recently I have noticed that more and more projects on instructables have involved the use of some sort of CNC machine, be it a laser cutter, 3d printer, milling machine, etc.Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. ThisDIY CNC Router Build (large Format 5x10ft, Rack and Pinion): This is a not so little summary of the build of my homemade CNC router, aka The Overpass. This instructable is more of a documentation of how I built my CNC and is not to be mistaken as a tutorial for buidling a CNC.

While commercially available CNC router machines can be expensive, building your own DIY CNC router can be a cost-effective alternative for hobbyists and small-scale manufacturers. In this comprehensive guide, we will explore the step-by-step process of creating a .A DIY CNC router (Computer Numerical Control) is a versatile tool that allows hobbyists, makers, and small businesses to build precise cuts, engravings, and 3D carvings. Unlike traditional handheld routers, CNC routers are automated and follow digital designs.

A CNC machine with an expansive 30x30" work area, supporing a router, laser, simple plotting and work monitoring camera. Control includes a tethered control box, game controller style jog control, and relay controlled AC outlets for all appliances. A compact router, baltic birch plywood, some basic hardware, and an off-the-shelf electronics kit are all you need to build your own computer-controlled router. This project is ideal for tech-savvy woodworkers looking to add a CNC router to their shop or beginners who want to give this type of woodworking technology a try.

make your own cnc machine

homemade cnc router plans

homemade cnc router machine

Just ordered a Hobart 140 and need to choose solid wire. I have an 80cf bottle being hydro'd, revalved and filled with ArCo2 75-25. Which wire should I be running for mainly auto body sheet metal? I plan on trying .023, not sure if it should be ER70s 2, 3 or 6. Thanks!Stick welding sheet metal can be done by welding DC electrode negative with 20-40A which is about the the lowest amperage settings that still allows to strike an arc. Suitable electrodes are E6011 for rusty or painted .

build cnc router machine|build your own cnc kit