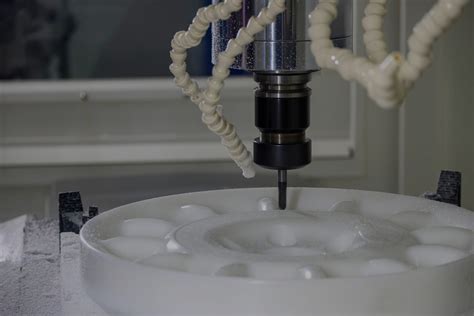

cnc machine polyproplene Polypropylene is easy to machine using CNC technology, and its low coefficient of friction makes it a suitable material for producing gears, bearings, and other parts that require high wear resistance. Additionally, polypropylene can be easily . Junction blocks are rectangular plates that use screws to connect each of the four service wires (from the phone co.) together with your inside wires. A junction block has four terminals that hold the wires together with screws.

0 · plastic for cnc milling

1 · plastic cnc machining near me

2 · lowest price cnc plastic machining

3 · cnc router for plastic sheets

4 · cnc plastic cutting near me

5 · cnc machine for plastic products

6 · cnc machine for plastic cutting

7 · best plastic for cnc milling

Is there anything in the NEC (or in my case, NYC amendments) that dictates the maximum length of whips? For example, if a recessed floor box that is used in a raised floor is .

Cutting polypropylene and similar soft plastics on the CNC is tricky. To avoid melting the plastic, you need the right bits, RPM, and feed speeds. Here is more info.At Miller Plastics, we’re your number one source for polypropylene machining, creating a wide variety of parts for your needs within any system. To handle your requests, we operate highly .

Get instant quotes on custom polypropylene machined parts with our Online CNC Machining Service. Make quick-turn prototypes and production parts in days with free standard shipping on all US orders. ISO 9001:2015, ISO 13485, and . Learn how to select the right plastic for CNC machining. Avoid pitfalls, ensure optimal performance, and reduce costs for your CNC machined parts with our comprehensive guide.Polypropylene is easy to machine using CNC technology, and its low coefficient of friction makes it a suitable material for producing gears, bearings, and other parts that require high wear resistance. Additionally, polypropylene can be easily . Plastic CNC machines are very intelligent. They do this by using computer programming to automate the process of machining. The equipment does this by controlling the tools that cut plastic materials very precisely so as .

plastic for cnc milling

In general, CNC machined plastic components make excellent prototypes and are readily available. In this guide, I’m going to help you align your project needs with the right material for CNC plastic part machining.

cnc manufacturing products

Polypropylene is widely used as Sheet stock for CNC Machine Manufacturing. When we prototype a small number of Polypropylene Parts, we typically CNC Machine them. Polypropylene has gained a reputation as a Material that . anyone machine polypropylene on a regular basis? how does it machine? is it a nice cutting plastic like delrin, or is is gumming and soft like uhmw? any.

Cutting polypropylene and similar soft plastics on the CNC is tricky. To avoid melting the plastic, you need the right bits, RPM, and feed speeds. Here is more info. In this insightful technical brief, we will discuss what goes into machining polypropylene and how it differs from other manufacturing options such as metal machining, injection molding, and 3D printing. Homopolymer vs Copolymer – What’s the Difference? The two main types of polypropylene available on the market are homopolymers and copolymers.At Miller Plastics, we’re your number one source for polypropylene machining, creating a wide variety of parts for your needs within any system. To handle your requests, we operate highly capable CNC machines, perfect for handling very precise polypropylene milling.

Get instant quotes on custom polypropylene machined parts with our Online CNC Machining Service. Make quick-turn prototypes and production parts in days with free standard shipping on all US orders. ISO 9001:2015, ISO 13485, and AS9100D certified. Learn how to select the right plastic for CNC machining. Avoid pitfalls, ensure optimal performance, and reduce costs for your CNC machined parts with our comprehensive guide.Polypropylene is easy to machine using CNC technology, and its low coefficient of friction makes it a suitable material for producing gears, bearings, and other parts that require high wear resistance. Additionally, polypropylene can be easily welded, making it an excellent choice for manufacturing parts that require sealing or bonding. Plastic CNC machines are very intelligent. They do this by using computer programming to automate the process of machining. The equipment does this by controlling the tools that cut plastic materials very precisely so as to take shape into what is desired.

In general, CNC machined plastic components make excellent prototypes and are readily available. In this guide, I’m going to help you align your project needs with the right material for CNC plastic part machining.Polypropylene is widely used as Sheet stock for CNC Machine Manufacturing. When we prototype a small number of Polypropylene Parts, we typically CNC Machine them. Polypropylene has gained a reputation as a Material that cannot be Machined. anyone machine polypropylene on a regular basis? how does it machine? is it a nice cutting plastic like delrin, or is is gumming and soft like uhmw? any.

Cutting polypropylene and similar soft plastics on the CNC is tricky. To avoid melting the plastic, you need the right bits, RPM, and feed speeds. Here is more info. In this insightful technical brief, we will discuss what goes into machining polypropylene and how it differs from other manufacturing options such as metal machining, injection molding, and 3D printing. Homopolymer vs Copolymer – What’s the Difference? The two main types of polypropylene available on the market are homopolymers and copolymers.

At Miller Plastics, we’re your number one source for polypropylene machining, creating a wide variety of parts for your needs within any system. To handle your requests, we operate highly capable CNC machines, perfect for handling very precise polypropylene milling.Get instant quotes on custom polypropylene machined parts with our Online CNC Machining Service. Make quick-turn prototypes and production parts in days with free standard shipping on all US orders. ISO 9001:2015, ISO 13485, and AS9100D certified. Learn how to select the right plastic for CNC machining. Avoid pitfalls, ensure optimal performance, and reduce costs for your CNC machined parts with our comprehensive guide.Polypropylene is easy to machine using CNC technology, and its low coefficient of friction makes it a suitable material for producing gears, bearings, and other parts that require high wear resistance. Additionally, polypropylene can be easily welded, making it an excellent choice for manufacturing parts that require sealing or bonding.

Plastic CNC machines are very intelligent. They do this by using computer programming to automate the process of machining. The equipment does this by controlling the tools that cut plastic materials very precisely so as to take shape into what is desired.In general, CNC machined plastic components make excellent prototypes and are readily available. In this guide, I’m going to help you align your project needs with the right material for CNC plastic part machining.

Polypropylene is widely used as Sheet stock for CNC Machine Manufacturing. When we prototype a small number of Polypropylene Parts, we typically CNC Machine them. Polypropylene has gained a reputation as a Material that cannot be Machined.

The key difference is that the main panel is the breaker box where the electrical power from the electrical company flows through and controls the power supply to the entire building, while a sub-panel installation is a .

cnc machine polyproplene|best plastic for cnc milling