sheet metal painting process pdf These paint and related coating standards help paint manufacturers and end- users in the appropriate testing and application procedures for the coating of their concern. 0.030 flux core wire requires less amps, has a lower deposition rate, and lower tensile strength than the thicker 0.035 flux core wire. Wire thickness is important and can affect overall weld quality. Mechanical properties like tensile strength and .

0 · sheet metal stamping process pdf

1 · sheet metal manufacturing process pdf

2 · sheet metal forming process pdf

3 · sheet metal drawing pdf download

4 · sheet metal design handbook pdf

5 · sheet metal design calculations pdf

6 · sheet metal calculation formula pdf

7 · forming process in sheet metal

A junction box is often needded when one is adding in to an existing circuit and this is often unavoidable. These days, the MF junction box is the better way to do it. Multi-way junction boxes used to be the standard way to wire lighting circuits for houses. Like this

The conversion coating process is a coating created on the surface of a metal part due to the reaction of the metal surface with a chemical. Examples of conversion coatings are phosphate, .

antique ammo box metal

1. Outline of Painting/ Coating Processes. 1.1 Outline. The objective of painting is to form a coating film on the surface of an object in order to protect the object and give a fine .These paint and related coating standards help paint manufacturers and end- users in the appropriate testing and application procedures for the coating of their concern.A document that provides a general review of the available paints for metallic coated steel sheet products is ASTM Specification A755/A755M, Steel Sheet, Metallic-Coated by the Hot-Dip .

sheet metal stamping process pdf

For those working with metal substrates, a conversion coating may be applied to metal prior to painting to improve adhesion, corrosion resistance, and thermal compatibility. Conversion .intermediate steps in a finishing process. Many are applied for protective reasons, some for rea-sons of appearance, and a few are simply clean-ing processes. Usually several steps are .

Global painting management process can be subdivided into the following main activities: Paint System Qualification (PSQ) o Used to qualify new paint systems and is .sheet metal forming processes. Bending, stretching and drawing of simple shapes are analysed, as are certain processes for forming thin-walled tubing. Where possible, the limits governing . Phosphating is a surface treatment process that is used to improve the corrosion resistance and paint adhesion of metal components. One of the most commonly used . To paint sheet metal, start by preparing the surface by removing any old paint, rust, debris, grease, and dirt. . The process of folding sheet metal to create intricate patterns and shapes is called “origami metal.” Inspired by the art of origami, this technique allows craftsmen to transform a flat piece of metal into three-dimensional .

sheet metal manufacturing process pdf

sheet metal forming process pdf

sheet metal company for bending process. They have used Ishikawa diagram for root cause analysis of sheet metal bending process problems and implemented FMEA procedure successfully. M.Dudek-Burlikowska[3] have suggested integration of quality management and quality control system for success of companies.

Once the primer is dry, the actual painting process begins. There are several techniques for applying paint, each suited to different applications: Brush Painting: Ideal for small areas and detailed work. It allows for precision but can be time .

Sheet Metal Forming 2.810 D. Cooper !“Sheet Metal Forming” Ch. 16 Kalpakjian !“Design for Sheetmetal Working”, Ch. 9 Boothroyd, Dewhurst and Knight

according §6.3 (depending on the thickness of the metal sheet and the paint system). All CO2 laser cutting must be mechanically pickled before painting (preferred laser cutting under nitrogen or argon).w-c-ss-014.pdf - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document provides specifications for painting and externally coating metal pipes and structures. It outlines the applicable standards, site conditions, technical requirements, safety requirements, inspection and testing procedures, marking, handling and storage, approvals, quality . Get popular posts related to About Paintings Sevices, Color Consultancy, Paints Suggestion, Modern Art, Abstract Art, Colour Suggestion & collection just like Metal Painting Procedures: Standard Process and Techniquestion/drying of the paint can result in VOC emissions. Class A finishes are achievable but may require signifi-cant manual work. For a typical spray painting process the ratio of direct to fixed costs is typically 1:2. A fully automated paint line is a significant investment. IMC may offer a better total cost of ownership for high

Sheet Metal fabrication is the creation of useful metallic parts and structures by the application of multiple fabrication processes. Various special tools are used in this process to convert sheet metals into useful components by minimal efforts. It is a value-added process to create machines, structures, or component parts following engineering drawings which usually serves as the . Wait at least 24 hours for the primer to dry. Now, fill a clean paint tray with an oil-based paint designed for metal. Apply the paint using a brush or roller, starting with the exterior edges to paint the trim before .

CLICK HERE to download the List of SOPs Document in PDF format. Please share this document with your clients, colleagues and senior officers. . Standard Operating Procedure for Safety Data Sheet (SDS) Management SOP-1112-050: Standard Operating Procedure for Continuous Improvement and SOP Review Process in Paint and Coating ManufacturingThe production cycle of a sheet metal product involves several phases from the raw material to the product ready for delivery which include: cutting, roll forming, bending, welding, punching, laser cutting, assembly of possible accessories, painting and packaging.

Sheet metal deforming processes involve changing and processing sheet metal without cutting it. Bending is one of the most critical forming processes, and it can be done using a brake machine. A sheet metal company can use this tool to bend sheet metal into V, U, and channels up to 120 degrees. Thinner sheets are easier to turn.10 Combined bending and tension of sheet 136 10.1 Introduction 136 10.2 Stretching and bending an elastic, perfectly plastic sheet 136 10.3 Bending and stretching a strain-hardening sheet 142 10.4 Bending a rigid, perfectly plastic sheet under tension 144 10.5 Bending and unbending under tension 145 10.6 Draw-beads 150 10.7 Exercises 151 11 .Paint Defects Manual ORIGIN AND POTENTIAL CAUSES PREVENTION TECHNIUES REMEDY 11 » The surface of the metal was contaminated (fingermarks, water) before application » Paint removed by chipping, scratches, etc. » Inadequate pre-treatment of the metal surfaces » Rust was not completely removed before refinishing » Destruction of paint film by .

I do, when it's on metal parts. Make test parts, and do your paint and bake process on those first, to prove it out. Power coating is actually the best solution, but it's a bit trickier for DIY (most of my powder coat experience is production sheet metals, I've got a .

sheet metal drawing pdf download

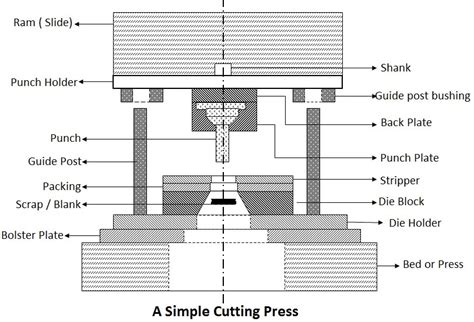

Chap 2 , sheet metal – p. 1 Sheet Metal Forming Processes • involves workpieces with a high ratio of surface area to thickness • plates, thickness > ¼ inch • sheets, thickness ≤ ¼ inch • typical items produced by sheet-metal forming processes: metal desks appliance bodies . hubcaps aircraft panels . beverage cans car bodiesPre-treatment process is simply a cleaning of metal surfaces and to modify the surface so as to make it easier for paint particle to have a proper bonding. This process includes : (1) Cleaning; this is mixture of mechanical and chemical cleaning. Mechanical cleaning means scratchThe sheet metal process starts with a two-dimensional metal sheet, then cuts & bends/connects them to make something three-dimensional. . Here’s where your product gets a sleek coat of paint and a shiny wax job. Surface treatment makes your product shine and protects it from the slings and arrows of life. . Download our free Sheet Metal . Request PDF | On Nov 13, 2024, Bharat Bhushan and others published Numerical Modeling of Incremental Sheet Metal Forming Process for Generating Complex Shapes on Ti6Al4V | Find, read and cite all .

The painting process for 3D-printed parts is quite similar to the process for other custom manufactured parts. Generally, paints used specifically for plastics are often best for 3D prints. . Does paint stick to sheet metal parts? The painting finish helps to add a custom look to a wide variety of parts. However, it does not always adhere to .

Sheet-Metal Forming Processes Process Roll forming Stretch forming Drawing Stamping Rubber-pad forming Spinning Superplastic forming Peen forming Explosive forming Magnetic-pulse forming Characteristics Long parts with constant complex cross-sections; good surface finish; high production rates; high tooling costs.the forming process, and the fact that dimensional variation is introduced at each bend, dimensioning in a single direction parallels the process and helps to control tolerance accumulation. Furthermore, allow a more generous bend tolerance (+/- .007”) as tighter tolerances, while achievable, will result in higher costs. The primary function of the Paint Shop on the Chevrolet side of the plant was to paint the front end sheet metal, but there were several other unique paint systems as well that processed many other parts. . Line, unless it needed a repair that couldn't be finished in the Paint Shop or if it got scratched during the assembly process after .

Get Sheet Metal Works Multiple Choice Questions (MCQ Quiz) with answers and detailed solutions. Download these Free Sheet Metal Works MCQ Quiz Pdf and prepare for your upcoming exams Like Banking, SSC, Railway, UPSC, State PSC. Download PDF Info Publication number JP2006122821A. . The entire repair method consists of a sheet metal process including an old paint film peeling process corresponding to the previous damaged part peeling process and the sheet metal process, and an order of the putty process before the painting process corresponding to the previous sheet .

sheet metal design handbook pdf

As many of you already know, I have too many lathes (6", 9", 10"). I was happy having a South Bend 9A 9" lathe, then got the free Logan 200 10" lathe. Ideally, I would like to .

sheet metal painting process pdf|forming process in sheet metal