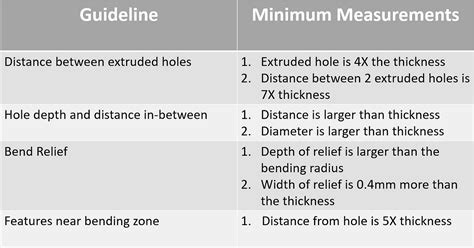

edge distance for holes in sheet metal The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. The recommended minimum distance between hole /slot edge to bend in sheet metal parts is three times the sheet thickness plus bend radius. Get wholesale prices on electrical boxes, whether it's an outlet box, junction box, single gang or 2 gang, when you shop Elliott Electric Supply. From arrestors to electrical boxes and wiring devices, we've got your electrical needs covered.

0 · sheet metal rib design guidelines

1 · sheet metal fabrication design guide

2 · sheet metal extruded hole design

3 · sheet metal drawing standards

4 · sheet metal drawing dimensioning

5 · sheet metal corner relief chart

6 · sheet metal bending guide pdf

7 · minimum flange length sheet metal

Look through the wide range of wholesale mechanical cnc turning parts listings on .

The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. The recommended minimum distance between hole /slot edge to bend in sheet metal parts is three times the sheet thickness plus bend radius.K Factor in sheet metal bending is a constant used to calculate sheet metal .Sheet Metal gauge chart converts sheet thickness from gauge to mm or inch. . 3. The minimum distance between the hole or slot and the edge of the sheet should be three times of sheet thickness. Min. Edge-to-hole distance= 3 x thickness. 4. If the custom sheet metal fabrication design has semi-pierced .

Minimum Distance from extruded hole to part edge. Extruding metal is one of the most extreme pressure applications in press working and generates lot of friction and heat. If an extruded hole is too close to the part edge, it can lead to .

It is recommended that the minimum distance between the extruded holes to part edge should be at least three times the thickness of sheet. Certain distance should be maintained between two . Outlined below are the minimum distances to be maintained between a gusset and other features like edges and holes in sheet metal components. These guidelines are calculated considering the material .To avoid distortion in sheet metal, holes must not be too close to an edge. For sheet metal 1/32 inch or less in thickness, all holes should be at least 1/16 inch from the nearest edge. The .

Be sure to place holes and slots at least 2 times the material’s thickness away from an edge to avoid a “bulging” efect. Holes should be placed at least 6 times the material’s thickness apart.

To avoid workpiece failure, DFM guidelines recommend a minimum distance (D1) from hole to the sheet edge equal to at least the plate thickness (T); we recommend a safe design zone of 1.5 to 2T. Also, when piercing multiple .Factors like bend radius and feature-to-feature cut distances should be considered. Be sure to follow design requirements and tolerances in this guide to ensure parts fall closer to design .The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. The recommended minimum distance between hole /slot edge to bend in sheet metal parts is three times the sheet thickness plus bend radius.Hole to edge clearance – A good rule of thumb for hole placement is to keep the hole at least one material thickness away from any edge. If the hole gets too close to an edge a bulge can form as shown below. Also note, if the hole is used for fastening two pieces together, extra web

3. The minimum distance between the hole or slot and the edge of the sheet should be three times of sheet thickness. Min. Edge-to-hole distance= 3 x thickness. 4. If the custom sheet metal fabrication design has semi-pierced or extruded holes, the distance from the edge or bend to them should be three times of sheet thickness.Minimum Distance from extruded hole to part edge. Extruding metal is one of the most extreme pressure applications in press working and generates lot of friction and heat. If an extruded hole is too close to the part edge, it can lead to deformation or tearing of the metal.It is recommended that the minimum distance between the extruded holes to part edge should be at least three times the thickness of sheet. Certain distance should be maintained between two extruded holes in sheet metal designs. If extruded holes are too close it . Outlined below are the minimum distances to be maintained between a gusset and other features like edges and holes in sheet metal components. These guidelines are calculated considering the material thickness and the specific features involved, aiming for a balanced and efficient design.

To avoid distortion in sheet metal, holes must not be too close to an edge. For sheet metal 1/32 inch or less in thickness, all holes should be at least 1/16 inch from the nearest edge. The minimum distance from an edge for thicker material should be .

sheet metal rib design guidelines

sheet metal fabrication design guide

Be sure to place holes and slots at least 2 times the material’s thickness away from an edge to avoid a “bulging” efect. Holes should be placed at least 6 times the material’s thickness apart.

To avoid workpiece failure, DFM guidelines recommend a minimum distance (D1) from hole to the sheet edge equal to at least the plate thickness (T); we recommend a safe design zone of 1.5 to 2T. Also, when piercing multiple holes, we recommend a spacing between holes (D2) greater than 2T.

Factors like bend radius and feature-to-feature cut distances should be considered. Be sure to follow design requirements and tolerances in this guide to ensure parts fall closer to design intent. Why Use Sheet Metal? Sharp edges will be broken and deburred by default.

The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. The recommended minimum distance between hole /slot edge to bend in sheet metal parts is three times the sheet thickness plus bend radius.

Hole to edge clearance – A good rule of thumb for hole placement is to keep the hole at least one material thickness away from any edge. If the hole gets too close to an edge a bulge can form as shown below. Also note, if the hole is used for fastening two pieces together, extra web 3. The minimum distance between the hole or slot and the edge of the sheet should be three times of sheet thickness. Min. Edge-to-hole distance= 3 x thickness. 4. If the custom sheet metal fabrication design has semi-pierced or extruded holes, the distance from the edge or bend to them should be three times of sheet thickness.Minimum Distance from extruded hole to part edge. Extruding metal is one of the most extreme pressure applications in press working and generates lot of friction and heat. If an extruded hole is too close to the part edge, it can lead to deformation or tearing of the metal.It is recommended that the minimum distance between the extruded holes to part edge should be at least three times the thickness of sheet. Certain distance should be maintained between two extruded holes in sheet metal designs. If extruded holes are too close it .

Outlined below are the minimum distances to be maintained between a gusset and other features like edges and holes in sheet metal components. These guidelines are calculated considering the material thickness and the specific features involved, aiming for a balanced and efficient design.To avoid distortion in sheet metal, holes must not be too close to an edge. For sheet metal 1/32 inch or less in thickness, all holes should be at least 1/16 inch from the nearest edge. The minimum distance from an edge for thicker material should be .

Be sure to place holes and slots at least 2 times the material’s thickness away from an edge to avoid a “bulging” efect. Holes should be placed at least 6 times the material’s thickness apart. To avoid workpiece failure, DFM guidelines recommend a minimum distance (D1) from hole to the sheet edge equal to at least the plate thickness (T); we recommend a safe design zone of 1.5 to 2T. Also, when piercing multiple holes, we recommend a spacing between holes (D2) greater than 2T.

sheet metal extruded hole design

sheet metal drawing standards

AP Lazer is your premier laser-cutting machine manufacturer and other laser equipment supplier. We boast a portfolio of CNC laser engraving machines for businesses seeking high-growth success in memorial care, education, sign making, woodworking, and furniture production.

edge distance for holes in sheet metal|sheet metal fabrication design guide