sheet metal fabrication equipment procurement Sheet metal fabrication is the process of shaping thin sheets of metal into useful structures and products. It involves taking flat sheet metal, cutting it into required shapes and sizes, and then . MarsteyOutdoor Electrical Connection Box, IP54 Waterproof Electrical Junction Box, Extra Large Plug Socket Cover Outdoor Power Cord Box for Christmas Light Strings, Timers, Extension Cords, Lead Wires

0 · Sheet Metal Shops: A Comprehensive Guide for Sourcing

1 · Sheet Metal Fabrication Guide

2 · Sheet Metal Fabrication Equipment; Sourcing and

3 · Sheet Metal Fabrication Equipment Market

4 · Procurement Tactics in the Sheet Metal Fabrication Equipment

5 · Procurement 101: An Introduction to Sheet Metal Fabrication

6 · Advantages of Strategic Sourcing in Steel Fabrication

Versatile Hole Configuration: The Security Camera Junction Box features three sets of holes positioned at 120-degree intervals, providing flexible mounting options for your surveillance cameras.

Sheet metal fabrication is the process of shaping thin sheets of metal into useful structures and products. It involves taking flat sheet metal, cutting it into required shapes and sizes, and then .

This buyer’s guide to sheet metal fabrication provides an overview of materials, processes and tolerances to help you make your supplier shortlist. This sheet metal fabrication guide will cover: Common types of metals used in sheet . Delve into our comprehensive guide for sourcing managers, covering essentials you need to know about sheet metal shops. Make informed procurement of sheets. With the global sheet metal fabrication equipment market valued at US$ 15.3 billion in 2022 and projected to grow at a CAGR of 2% over 2023-2028, the industry faces the imperative of enhancing its procurement capabilities. Find the strategic sourcing benefits in the steel fabrication industry. Maximize purchasing power, minimize risks, and optimize supply chain efficiency.

In the dynamic sheet metal fabrication equipment market, effective procurement strategies are essential for sustainable success. Collaboration with reputable suppliers and .

Sheet Metal Shops: A Comprehensive Guide for Sourcing

Sheet Metal Fabrication Guide

This Sheet Metal Fabrication Equipment procurement intelligence report has enlisted the top suppliers and their cost structures, SLA terms, best selection criteria, and negotiation.Applications of sheet metal fabrication. Sheet metal fabrication spans various sectors, from automotive to construction. Construction Channels used in construction. Sheet metal fabrication plays a vital role in the construction .Sheet metal fabricators cut, form, and assemble pieces of flat metal sheets to create various parts and structures. These include containers, chassis, enclosures, frames, brackets and mounts, barricades, vents, and panels. .From machining and sheet metal fabrication to welding, assembly, finishing, and inspection, we have the expertise and resources to see your project through from start to finish. In addition to our core services, we also offer materials .

Purchasing used sheet metal tools, sheet metal equipment or sheet metal fabrication tools, whatever you call them, makes sense for a variety of reasons. First, and perhaps the most important reason, for say a new start-up business, or a company just starting a new capability, is cost. Used metal fabrication tools are a bargain when compared to .Sheet Metal Fabrication Equipment Procurement Research, Pricing Strategies, Negotiation Strategies, Cost Modeling, Procurement Best Practices, Strategic Purchasing, Pricing Trends, Market Research for Procurement Professionals. Sheet metal machines are widely used in various manufacturing industries for shaping, cutting, and forming sheet metal into different components. Some of the industries that extensively utilize sheet metal machines include light industries such as electrical and medical equipment, all the way up to heavy industries such as automotive, rail, oil and gas, as well as .

Here are some ways leading fabricators are doing so today. 7 Sheet Metal Fabrication Best Practices to stay competitive and improve profitability. Running a sheet metal fabrication shop requires careful planning, efficient operations, and a focus on quality. Here is a list of best practices to consider: Our equipment is state-of-the-art. This equipment is designed to give our customers the highest quality product. . Our operation scalability and purchasing power helps our customers face the challenges of demand fluctuations, design changes, short product lifecycles, and short lead times. . Trade Consultants Sheet Metal Fabrication For over .

Sheet Metal Fabrication Equipment; Sourcing and

Integrated machinery database together with experienced team will promise you the optimum to breakthrough. . Sheet Metal Fabrication . Blank Production Line. All Industries, Custom Fabrication Services, Mechanical Parts & Fabrication Services, Sheet Metal Fabrication . Metal Frame Making Machinery.Wier(Beijing) New Material Co.,Ltd: Wier - Professional sheet metal fabrication factory in china. Custom any sheet metal parts and stamping parts for your project. . manufacturing capability ensures that we can provide you with turnkey products and solve the trouble of decentralized purchasing. . State-of-the-art fabrication equipment and a .

Originally Published on: SpendEdge |Procurement Challenges Troubling Executives in the Sheet Metal Fabrication Equipment Market The progress of our modern world is a testament to the remarkable.At Wisdometal, we specialize in sheet metal fabrication, delivering high-quality solutions to clients across the United States and Europe. With a commitment to precision,quality,innovation, and customer satisfaction, we are dedicated to exceeding expectations in every project we undertake.29 Full Time Sheet Metal Fabrication jobs available in Rochester, NY on Indeed.com. Apply to Cable Installer, Diesel Mechanic, Industrial Electrician and more! . ventilation systems, and refrigeration equipment. Oversee a team of HVAC installers, ensuring adherence to project timelines and quality standards. Read and interpret blueprints .BROAD CAPABILITIES & SERVICES. SWF offers complete, turnkey support for any project that requires commercial or industrial metal fabrication. Our knowledgeable and dedicated team of 130 professional tradespeople can craft nearly any product made of carbon steel, heavy plate, stainless steel, sheet metal, or aluminum – while maintaining rigorous quality standards and .

steel metal fabrications

affordable sheet metal working machinery. Tin Knocker Machines. HM Machinery. ERBEND Machinery. Other New, Pre-Owned & Demo Machines. New, fully-warranted machines at . Tin Knocker’s sheet metal fabrication machines are .Unraveling Procurement Challenges in the Sheet Metal Fabrication Equipment Market Sheet metal fabrication equipment procurement poses unique challenges. Delve into the issues that trouble .Most manufactured machinery and equipment these days utilize custom fabricated sheet metal components, along with others like CNC machined parts, structural frames, plastic injection molds, wire harnesses, and COTS items.. .Structural steel fabrication is one of the most significant applications of steel, used to construct buildings, bridges, and other infrastructure. It is also used in the manufacturing of equipment and machinery. Primary Materials Used in Steel Fabrication. Sheet Metal & Plate Metal – This allows fabricators to mold the pieces into specific .

NEW YORK, April 30, 2021 /PRNewswire/ -- The Sheet Metal Fabrication Equipment market will register an incremental spend of about USD 87.6 Billion.Originally Published on: SpendEdge |Procurement Challenges Troubling Executives in the Sheet Metal Fabrication Equipment Market The sheet metal fabrication equipment market revolves around the.purchasing personnel to locate multiple vendors for different services. 2. PRODUCT & ITS APPLICATION: Sheet metal Fabrication is a value added process that involves the creation of machines parts, panels, and structures from various steel sheet as raw materials. Sheet Metal fabrication jobs usually start with design drawings including precise

Mac Metal Sheet Metal Fabrication Services—Mac Metal specializes in sheet steel, light plate, aluminum, copper and stainless steel fabrication using Solid Works CAD system we can reverse engineer to create drawings and models. . Collaborate with Procurement, Engineering, Technical Services and Quality to fabricate complete part geometries .Metal Fabrication Supplier, CNC Machining, Sheet Metal Fabrication Manufacturers/ Suppliers - Xiamen Openex Mechanical Technology Limited

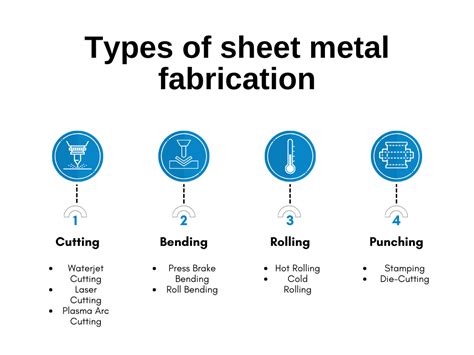

Precision sheet metal fabrication is a common manufacturing process where the structure of a metal workpiece is cut, bent, and assembled by machining. There are any number of operations that are performed in the creation of a finished sheet metal product.This service is currently provided to Design Engineers, Project Managers and Purchasing Agents in the OEM market place. The Process. We have the capability of creating all tooling in-house, which accelerates our ability to process the prototype vs. .In the expansive realm of our services, sheet metal fabrication takes center stage, showcasing our mastery in delivering comprehensive solutions that meet the unique needs and specifications of each client. As a team, we specialize in seamlessly integrating our expertise in sheet metal fabrication with a deep understanding of our clients .What is sheet metal fabrication? Sheet metal fabrication is a set of manufacturing processes used to transform metal sheets into useful products. We can broadly classify sheet metal processes into cutting, deformation, and assembly. Sheet metal work may be more affordable than casting and machining for hollow or mostly flat objects.

Sheet Metal Fabrication Equipment Market

$16.98

sheet metal fabrication equipment procurement|Procurement Tactics in the Sheet Metal Fabrication Equipment