how to make a joggle in sheet metal A joggle in sheet metal is a small offset or bend to create an overlapping joint on a flush surface. The offset bending process creates two opposite bends with equal angles in a single action. The joggle bends are in .

3G 35mm Deep Triple Galvanised Steel Box with fixed lug and three brass terminals SG335 Galvanized steel construction 1mm thickness (+/- 1%) 35mm depth 6 fixed mounting lugs With .

0 · shrinking sheet metal by hand

1 · sheet metal joggle tool

2 · open hem sheet metal

3 · lightening holes in sheet metal

4 · hand forming aluminum sheet metal

5 · forming sheet metal by hand

6 · forming joggles in sheet metal

7 · forming aluminum sheet by hand

The Stampede 4X4 Kit is designed Traxxas Tough™ to handle all the 4-wheel drive monster mayhem you can dish out. Its tall ground clearance and long-arm suspension make Stampede 4X4 feel unstoppable.

shrinking sheet metal by hand

A joggle, often found at the intersection of stringers and formers, is the offset formed on a part to allow clearance for a sheet or another mating part. Use of the joggle maintains the smooth . How do you make Joggle in Sheet Metal Fabrications? Step one is to ensure to prepare the sheet metal cut it to the size and shape you want and set up the press brakes. Ensure you position the sheet metal ensuring it is . Learn about joggling and its function. Follow our mini series for more practical tasks. . For more info visit our website https://code1mx.com and info on our .Joggle forming is a process where multiple bends are created on a sheet metal, resulting in angles less than 90 degrees. This technique often involves bends in opposite directions and is used to create a small offset near the edge of the .

How to make a joggle in sheet metal. Jadestone Machine Tool Co Ltd Press Brake. 466 subscribers. Subscribed. A joggle in sheet metal is a small offset or bend to create an overlapping joint on a flush surface. The offset bending process creates two opposite bends with equal angles in a single action. The joggle bends are in . About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

Create the Runout_Joggle_Formula.txt or Runout_Joggle_Formula.xls table, as suggested below. Click Sheet Metal Parameters and select the Joggles tab. Select Design Table in the Joggle Formula list. Hems and jogs are easy in 3-D CAD, but they require planning, tooling, and setup in the fab shop. This is a CAD setup for an open hem on two edges. Note that closed hems, teardrop, and edge bead are all available from .To create a jog feature on a sheet metal part: Sketch a line on the face of a sheet metal part where you want to create the jog. Alternatively, you can select the jog feature before you .In the following example, you will create a joggle defined on a surfacic flange, but this scenario is also valid for a joggle created on a web. Open the Joggle1.CATPart document. Click Joggle in the Aerospace Sheet Metal .

Joggle in Sheet Metal: Industrial metalworking machines are pivotal to the modern manufacturing landscape, transforming raw metal into precision-engineered parts through a variety of machining processes. These machines shape, cut, bend, and finish metal, and they form the backbone of industries ranging from automotive and aerospace to heavy . Figure 1 Upspring, or upsweep, tools are used to form two bends that are too close together for conventional forming methods. The horizontal tool is designed to offset the material by one material thickness. Figure 2 . Overdue Improvements to Inventor Sheet Metal: (#14) Sheet Metal - Enable Aviation Specific Features; John's previous Idea (that I merged with this one - my apologies) was perhaps the closest stand alone request. To correct this I feel authoring a new Idea, containing Sheet Metal Joggle feature in the title, would be the best approach moving .

A joggle is an offset formed to provide for an -overlap of a sheet or angle which is projecting in the same plane. The inside joggle radii should be approximately the same as used for straight bending. I have attached a pdf of a part I'm working on in Inventor. I am needing the joggled area to be vertical, as it's shown on the pdf. I tried using the flange, but it follows the bend line. I appreciate any suggestions, etc. you have.

Learn catia V5 Tutorials for beginners |Aerospace Sheet Metal Design | Joggle | Part 3In this video we will see the joggle operation in aerospace sheetmetal .

NX 11 features sheet metal capabilities that are particularly helpful to those of you who work in the aerospace industry. In this tutorial, Sam Kuan shows you how to create a leading edge rib in the tail of an aircraft by using Advanced Flange, Joggle, and Lightening Holes. To begin, we have a tail section of an aircraft in which there are two .

Working with sheet metal jogs, sketched bends and cross breaks in Solidworks

A reader recently asked for guidance in using 3-D CAD for sheet metal parts. We continue the theme from last month: Skilled designers know how the sheet metal parts get bent. The recommended CAD work flow is to design with size and function of the end product as the modeling intent. HerrTick wrote: ↑ Tue Nov 02, 2021 1:02 pm There's an persistent and pernicious dogma in CAD (not just SW) that sheet metal parts must consist of only sheet metal features from the sheet metal app. Utter tosh! Z-bends (including jogs) are a great reason to ditch this dogma. In many cases, it is far simpler and better for the design (you know, the thing that matter most) to . 6. On his way back through the crowd three different men joggle and spill parts of the beer. 7. How do you put joggle on sheet metal? To form the joggle, use the following procedure: Lay out the boundary lines of the joggle where the bends are to occur on the sheet. Insert the sheet in the brake and bend the metal up approximately 20° to 30 .Thanks for replying! Let me give you more insight on why we had to make partial sheetmetal cutout on surfacic flanges. Big brains at my company are planning to machine the chemical milled surfaces on a router using special fixtures (customer has also agreed with this process).The sheetmetal part that i am working on is of 0.1” stock and it has chemical milled surfaces up-to .

If you go into modify > Change Parameters and find the name of the thickness under sheet metal rules (in my case it's "d1"), you can create a new parameter called JBendHeight equal to sqrt(2)*d1 and specify that as the height of the first 45 degree bend. You should be able to then reuse that parameter as needed within the same part.

sheet metal joggle tool

A joggle die is optimized for one material and one thickness and temper. Have your folks make an exemplar of the die's product using the correct material, measure it and make a standard detail drawing of the exemplar, and a superimposed layer or sheet showing how the finished features relate to the dimensions of the actual die.QWORK 5mm Hand Joggle Panel Flanging Plier, Hole Punch Sheet Metal Repair Welding Edge Setter Pliers - Amazon.com . Metal Hole Punch Professional Heavy Duty Hole Puncher Hand 3/32in to 9/32in for .

Anyway, when I cut the Trunk Floor out all those months back I had to trash a strip of metal that essentially stiffened the transmission/gearbox mounts. This innocent looking piece of metal mated perfectly to the trunk floor . I have been trying to model the part shown in the attached photos and I'm having trouble. I started by creating a flat version in the sheet metal environment, but I can't figure out how to roll it into a round shape. I also tried extruding a contour flange of the round shape, but then I can't figure out how to add the fingers to it. Would someone be able to show me how it's . With only 1 piece of angle iron, 1 piece of wood, and some hardware, I made a sheet metal brake that can make perfect bends, as well as make radius bends wit. Find The Tools I Use Here -https://www.amazon.com/shop/thefabforums*As an Amazon Associate I earn from qualifying purchases*On this episode of The Fab Forums.

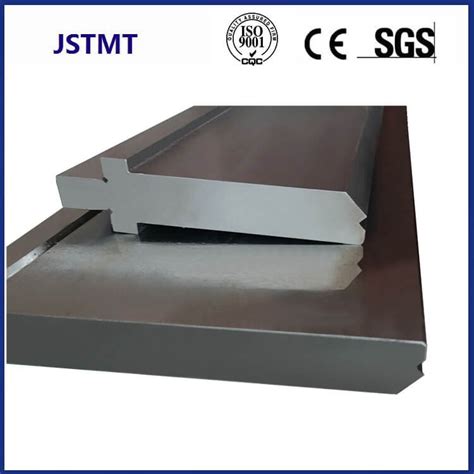

A joggle bend in sheet metal (at top of image) and a hand joggling tool. Joggling, [5] also known as joggle bending, is an offset bending process in which two opposite bends with equal angles are formed in a single action creating a small s-shape bend profile and an offset between the unbent face and the result flange that is typically less . http://www.cadxpand.com , How to use the SolidWorks Sheet Metal tool, Jog!SolidWorks Sheet Metal, SolidWorks Training, SolidWorks Support, online training co.I am trying to make a model for a round sheet metal flange with a joggle. The inside diameter of the part is 8 inches and the legs of the flange are 1 inch each. The joggle extends at least 1 inch as well and is riveted as shown. I have attempted to make the flange using a contour roll (359 degrees) but then I can't get the joggle to build.

A joggle, or a small offset near the edge of a piece of metal, is sometimes needed when creating sheet metal. . After that, use the thicken command (keep in mind we are still in the 3D Model workspace) and give it the sheet metal rule thickness. Make sure to thicken the part outwards so this can work. Next, let’s add some bends to the part .Solidworks Sheet Metal Corner Treatment For Beginners to understand how to user corner option in Solidworks sheet metal and how to use Solidworks sheet metal.

soldate sheet metal heating & air

Tri-State Roofing & Sheet Metal Company’s Morgantown location serves customers in northern, central, and western West Virginia; southeastern Ohio; and southern Pennsylvania.

how to make a joggle in sheet metal|open hem sheet metal