sheet metal 180 degree bend You can find your bend allowance with the following formula: (π/180) x B x (IR + K x MT) = bend allowance (BA), where B is the angle . 4 Pcs 4 Hole Long U-Shape Bracket, 1-1/4" Inner Wide, 4-5/8" High, Carbon Steel U .

0 · sheet metal bending dimensions

1 · sheet metal bending angle

2 · sheet metal bend size

3 · sheet metal bend chart

4 · sheet metal bend

5 · bending sheet metal

6 · 180 degree bending sheet metal

7 · 180 degree bending method

Universal U-Bolt Clamp Antenna Mount Bracket for Starlink V2 Pipe Adapter, .

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a . You can find your bend allowance with the following formula: (π/180) x B x (IR + K x MT) = bend allowance (BA), where B is the angle .

cello newton electric lunch box with 4 containers

Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal bending operations. This .Bend Allowance Calculator. Calculate the bend allowance, bend deduction, and setback for a bent piece of sheet metal, or use this information to determine the K-factor.This is a step-by-step guide. First, you need to determine the radius and bend angle. Use the following formula: Bend allowance = (p/180 x Bend angle x (Radius x K-Factor + Thickness). .

Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a .

center sheet metal bronx ny

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information. Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc. . you can get a result anywhere between 90 and 180 degrees. Though less .Bends up to 1 1/4" of Sheet Metal From 90° to 180° - Ideal for Hems The Wuko Bender 4040 is an ideal tool to create hems. It features a thin bending wheel, which allows for bends from 90° up to 180°.Another great tool from the Wuko Arsenal.Wuko benders are a must have tools for metal roofers, those bending metal without a brake / box brake and those making radius roof panels . Specify the Bend Angle: • Input the required bend angle in degrees. • The tool will compute the arc length, bend allowance, and bend deduction, essential for determining material requirements and tooling setup. . Imagine .

cello world relish 4 stainless steel lunch box

Good Morning, I've created a sheet metal part and have set my parameters. In using the fold feature, cannot create bend past 180 degrees. Radius is large enough (21") and sheet is long enough as there is still flat sheet after a 180 degree bend. How do you create bends past 180 degrees? Thanks for the help! ; Darren

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright . However, it can also be used for the calculation of non-90-degree sheet metal unfolding, but the bending deduction value for non-90-degree bending needs to be used according to the bending coefficient table. . 0° – 180° Bend Allowance Chart for Sheet Metal Bending; 28 Sheet Metal Bending Problems and Solutions; Don't forget, sharing is .Sheet metal hem radius, there is only one 180-degree bend in a hem. Some hems are closed, which means that the inside bend radius is zero. . The hem has one curve rather than two, in contrast to the U-channels’ two bends. While sheet metal jog is just a pair of equal and opposing bends placed closely together to produce a sluggish Z offset . annealed to 4.75 mm 0.5T for 180 degree bend cold-rolled, quarter hard 0.5T for 180 degree bend to 1.27 mm cold-rolled, quarter hard 1T for 90 degree bend 1.3-4.75 mm . Upvote 0 . The max-minimum inside radius sheet metal (unhardened) can be formed on the brake press is .63 x material thickness. It cannot be formed tighter without creasing .

Sheet Metal: Simulation: SimulationXpress: Sketching: Sustainability Products: SolidWorks Utilities: Tolerancing: Toolbox: Weldments: Workgroup PDM: Troubleshooting: Glossary: 180-Degree Elbows or Bends for Piping. You can use 180-degree elbows or create 180-degree bends in pipes. Parent topic: Elbows. Search '180-Degree Elbows or Bends for .

This Sheet Metal Bending Brake makes it easy to fabricate metal panels up to 18" wide and is the perfect tool for fabricating small patch panels. . 180 degree bend? Asked by: John1999. This break will bend a 90-degree bend max. Answered by: Bob G. Date published: 2021-06-13. y_2024, m_11, d_13, h_7CST .

The bend allowance is an approximation of this bend's total length (our arc length calculator is the perfect tool to calculate the length of a curved line segment).. Usually, your supplier will have a bend allowance chart for each type of bend and material, such as a 90-degree bend deduction chart (we will cover bend deduction later on in the text).In this week's episode Lennart will show you HOW TO BEND THE FLANGE BELOW 90 DEGREES.The most frequently asked question about sheet metal is: "Why is it not .

sheet metal bending dimensions

sheet metal bending angle

Adding a hem means to attach a sheet which is folded by 180 degrees. To add a hem you click an edge to specify where you want to add it. . Bend and corner reliefs are necessary to prevent any undesired material distortion during manufacturing. . Based on the message Creo Elements/Direct Sheet Metal issues, you can decide to continue (click . How to create a 180 degree bend in sheet metal over a large radius I want to create a rectangular bracket to wrap around a 1 inch tube. This has to be simple but I'm a newbie and cannot figure out how this should be done in F360. I started with a flange using a custom material of 20g ss. Looks like sheet metal bends are not designed to handle .

Sheet metal bend Question I am trying to make a 180 degree bend that also changes direction 90 degrees. (As shown by the folded paper). I tried extruding at a 45 degree angle and using that as a flange, but it is not working how I .

sheet metal bend size

Working on the Hem. The hem is a single, 180-degree bend. Some hems are closed — basically a zero inside bend radius. If the hem has a radius greater than zero, it resembles a U in cross-section.The bend allowance and bend deduction are two measures that relate the bent length of a piece of sheet metal to the flat length. The bend allowance describes the length of the neutral axis between the bend lines, or in other words, the . About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

Some tooling I designed for the press brake to bend large radius 180 degree bends. This is .125" thick aluminum.#3dprinting #pressbrake #diy

Almost all engineering materials are available in sheet form, and thus can be bent to some degree. There are, however, different processing limitations with different materials because of their different inherent properties. . Bends on the same side of a metal sheet that are too close will interfere with the tooling, and bends on opposing .The lack of this feature / ability to create a 180 degree return bend is a major weakness when creating sheet metal. I have tried all methods I know and none work. 179 degrees is not good enough from software that is paid for! 0. bryan_lagrange Member, User Group Leader Posts .

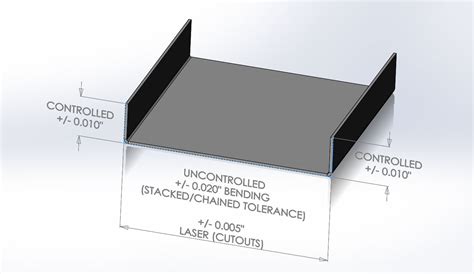

To achieve higher accuracy, it is recommended to design sheet metal bends with a small bend radius and rounded corners. Avoid using large arcs, as illustrated in Figure 9, since they are challenging to produce and control for quality. . 6.10. 180° Bending. 180-Degree Bend Method: As depicted in Figure 30, the process begins by folding the . Because sometimes you will need to work around a bend, and you may need to know sheet metal bend allowance. . The 0.0078 value comes from (π/180) × 0.446. Note that for the bend allowance, the bend angle is always measured as complementary (see Figure 1). Outside Setback (OSSB) OSSB = [Tangent (Degree of bend angle / 2)] × (Inside bend . “Turning the Drive” means preparing the 2 joining edges of the Straight Duct or Fitting for connection in the field with a Drive Cleat and the Cleatbender is the machine that performs this task.It does so by using 1/2″ of metal and bending it outward to form a 7/16″ Open Hem at 180 degrees. Unlike the Cheekbender which has just tug of the handle, the .

a great tool to have for metal fabrication. Bending a 180° is useful in furniture, panels and general jobshop work. Check this one out. a great tool to have for metal fabrication. Bending a 180 .

Springback in a 180-degree U bend = {[11.1/(1.57 × 0.9)]/2] × 2= 7.856 degrees of springback. . Steve Benson is a member and former chair of the Precision Sheet Metal Technology Council of the Fabricators & Manufacturers Association International®. He is the president of ASMA LLC, 2952 Doaks Ferry Road NW, Salem, . As the bender moves down, the rocker makes contact with the sheet metal. One contact point acts as a holding pad, while the opposite contact point rotates, creating the bending action. After the bend is completed and on the press's returnstroke, the spring forces the rocker to return back to its original or idle position (Figure 1).

centering a junction box between studs

central junction box 03 super duty

$4.37

sheet metal 180 degree bend|bending sheet metal