shearing process in sheet metal pdf Shear cutting of sheet metal 2.1 Shearing in general Shearing is a process for mechanical straight cutting of sheet metal without chip formation between two, against each other, moving tools. . I was wondering if it was against the code to leave the conductors in the junction box. They are labeled. Is it required to disconnect these conductors from the circuit breaker?

0 · trimming operation in sheet metal

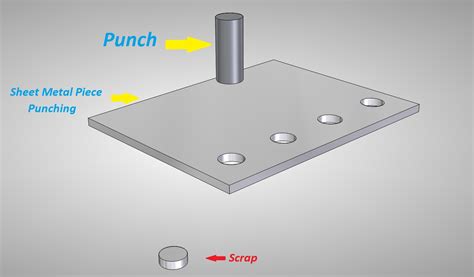

1 · punching operation in sheet metal

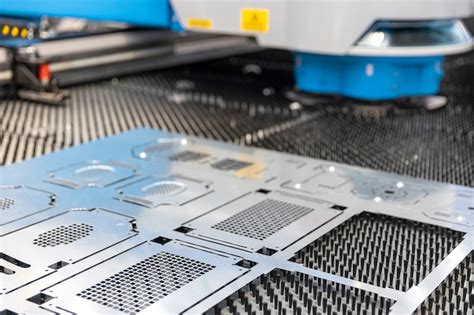

2 · perforating operation in sheet metal

3 · lancing operation in sheet metal

4 · difference between shearing and cutting

5 · difference between shearing and blanking

6 · clearance in sheet metal cutting

7 · blanking operation in sheet metal

In rare instances like this, I have added two junction boxes about 14 inches apart and two outlets instead of the one I needed. I cut the existing wire so there was enough wire going into each box and added new wire going new box to new box. I did this to avoid removing/modifying existing boxes that would have done damage to existing walls.

•Shearing - using a machine called power shear or square shear. •Blanking – shearing a closed outline (desired part called blank) •Punching – sheared part is slag (or scrap) and remaining .Objectives. By the end of today you should be able to. .describe different forming processes, when they might be used, and compare their production rates, costs and environmental .

Blanking: shearing process using a die and punch where the exterior portion of the shearing operation is to be discarded. Perforating: punching a number of holes in a sheet. Parting: .Shear cutting of sheet metal 2.1 Shearing in general Shearing is a process for mechanical straight cutting of sheet metal without chip formation between two, against each other, moving tools. .

The objective of this work is to provide an overview of the factors that influence the quality of the sheared edge, speed limitations, and life of tooling elements in the sheet metal .Shearing processes -- processes which apply shearing forces to cut, fracture, or separate the material. Forming processes -- processes which cause the metal to undergo desired shape .

The two most basic and oldest metal working operations are shearing and bending. Shearing is defined as the mechanical cutting of large sheets of metal into smaller pieces of predetermined . Request PDF | Design and validation of a sheet metal shearing experimental procedure | Throughout the industrial processes of sheet metal manufacturing and refining, shear cutting is widely used .

Sheet metal Shearing Bending Drawing imparting stiffness to parts; can be controlled by proper tool and die design. Quality of sheared edges : Depends on process used; edges can be rough, not . Blanking is a cutting process in which a piece of sheet metal is removed from a larger piece of stock by applying a great enough shearing force. In .

Sheet-Metal Forming Processes Process Roll forming Stretch forming Drawing Stamping Rubber-pad forming Spinning Superplastic forming Peen forming Explosive forming Magnetic-pulse forming Characteristics Long parts with . Factors Influencing Metal Shearing. The success of sheet metal shearing depends on several factors. A well-planned approach ensures that the metal shearing process remains efficient and minimizes waste. Carefully evaluate each factor to determine how it will interact with your specific materials and machinery. Material Characteristics SHEET METAL PROCESS - Download as a PDF or view online for free. Submit Search. SHEET METAL PROCESS • Download as PPT, PDF • 1 like • 645 views. R. Raja P Follow. The document discusses various sheet metal processes including shearing, bending, drawing, and special forming processes. It provides details on: - Common shearing operations .sheet_metal.pdf - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document discusses common sheet metal forming processes. It describes that shearing involves cutting sheet metal using a punch and die, bending changes the shape of sheet metal by applying stresses, and deep drawing forms flat sheet metal into cylindrical or box shapes using a punch .

Even after the development of various non-conventional processes for sheet metal cutting, the shearing process remains the most preferred process in mass production. Several innovations have improved working conditions in shearing process applications. But the ever-increasing demands from the customer are pushing the field to understand the process in .

ds-2ce56d1t-vpir junction box

trimming operation in sheet metal

Types of Shearing •Simple shearing- sheets of metal are sheared along a straight line •Slitting- lengthwise shearing process that is used to cut coils of sheet metal into several rolls of narrower width Figure 17-5 Method of smooth shearing a rod by putting it into compression during shearing. Figure 17-6 A 3-m (10ft) power shear for 6.5 mmShearing Process 1. Punching: shearing process using a die and punch where the interior portion of the sheared sheet is to be discarded. 2. Blanking: shearing process using a die and punch where the exterior portion of the shearing operation is to be discarded. 3. Perforating: punching a number of holes in a sheet 4. Parting: shearing the sheet into two or more pieces

PDF | Metal Forming Processes, Bulk forming,Sheet metal forming | Find, read and cite all the research you need on ResearchGate. . such as the specific shearing process, material, and sheet .Surface condition of sheet : Depends on rolling practice; important in sheet forming as it can cause tearing and poor surface quality Classification of sheet metal working processes Sheet metal Shearing Bending Drawing The term "shearing or cutting process" is refers to a specific cutting process that produces straight line cuts to separate a .Sheet Metal Cutting (Shearing) - Free download as PDF File (.pdf), Text File (.txt) or read online for free.

Sheet Metal Forming 2.810 D. Cooper !“Sheet Metal Forming” Ch. 16 Kalpakjian !“Design for Sheetmetal Working”, Ch. 9 Boothroyd, Dewhurst and Knight

For the shearing process in sheet metal, sheets are fabricated into multiple components – all of which can now be used to manufacture different items. The metal material itself is cut precisely and accurately, with the objective being the overall removal of any unwanted or unrequired particles. Accuracy is the name of the game here, and the .(a) Shaving a sheared edge. (b) Shearing and shaving combined in one punch stroke. (a) (b) Sheared edge Sheet Die Sheet Die Clearance FIGURE 7.12 Examples of the use of shear angles on punches and dies. Compare these designs with that for a common paper punch. (a) (b) (c) (d) Double-bevel shear Convex shear Blank thickness Shear angle Punch Die . The growing use of sheet metal in various industries such as automotive, packaging, medical appliances, cylinder production, Apparatus construction, Tank construction, Aircraft bodies, Missile production, Satellite dishes, road building and road signs, and household appliances, is attributed to its ease of manufacturing, handling, and use. To meet customer .

Advantages of Sheet Metal Shearing. Precision and Clean Cuts: Shearing provides immaculate and straight edges, essential for the aesthetics and functional integration of parts, especially when precision is crucial.This makes it ideal for high-end projects where every millimetre counts. Efficiency: The process is highly efficient, allowing quick cuts without .Do whatever you want with a What is the Shearing Process in Sheet Metal: fill, sign, print and send online instantly. Securely download your document with other editable templates, any time, with PDFfiller. No paper. No software installation. On any device & OS. Complete a blank sample electronically to save yourself time and money. Try Now!

Shearing: This is nothing but cutting of sheets by shearing action. Sheet forming: Sheet metal forming involves forming and cutting operations performed on metal sheets, strips, and coils. The surface area-to-volume ratio of the starting metal is relatively high. Tools include punch, die that are used to deform the sheets. Classification of .

ºõ³ .Sheet Metal Shearing & Bending Fundamental Manufacturing Processes Study Guide, DV03PUB18 - 4 - Review Questions 1. When a workpiece is sheared to shape and size in a die, it is called a: a. workpiece b. plug c. blank d. billet 2. Rake refers to: a. a cut angle of 45 degrees or more b. the vertical offset of a knife blade .

punching operation in sheet metal

Selected process principles of metal forming: Rolling, Extrusion, Drawing, Forging; Sheet metal forming: Shearing operation, bending, Deep drawing, Spinning, Stretch forming; Force and work; Material consumption; Die design. 2. Principles of Selected Joining and Assembly Process in welding: Electrical arcMechanical Metallurgy Questions and Answers – Sheet-Metal Forming – Shearing and Blanking. This set of Mechanical Metallurgy Multiple Choice Questions & Answers (MCQs) focuses on “Sheet-Metal Forming – Shearing and Blanking”. . and the process of sheet metal forming will be easiest if the surface area of sheet to be drawn is high .• sheets, thickness ≤ ¼ inch • typical items produced by sheet-metal forming processes: metal desks appliance bodies . hubcaps aircraft panels . beverage cans car bodies . kitchen utensils • sheet metal is formed by rolling; if the metal is thin, it is generally coiled • shearing, bending, stretching are the most common

tractor-plowing discs. Therefore, the use of a circular sheet metal shearing machine to produce circular blanks is more economical. 3. GENERAL OBJECTIVE The general objective of the research is to design and fabricate a circular sheet metal shearing machine for small-scale and light work. 3.1 Specific Objectives of this Research are Illustrated . Shearing metal - Download as a PDF or view online for free. Submit Search. Shearing metal • Download as PPS, PDF • 18 likes • 7,548 views. AI-enhanced description. Mohamed Yaser Follow. Shearing of metals is a sheet metalworking process used to cut relatively thin sheets of metal less than 6mm thick. Sheet metal parts are commonly used in .Shear of metal sheet [8] 2 Shearing Operation When two blades cut a piece, the process is called shearing [7], but the process is called blanking, piercing, notching, or trimming when the blades are at an angle, while both are referred to as shearing operations in terms of tool design and material behaviour [7].

dual electrical outlet box

A junction box provides a code-approved place to house wire connections, whether for outlets, switches, or splices. Here's how to install one.

shearing process in sheet metal pdf|perforating operation in sheet metal