how to hem sheet metal In sheet metal fabrication, the hemming process involves bending the same part’s sharp edges to form a reinforcement channel. This process is widely used across the automotive and electronics industries. It cuts thin sheet . Twisted Metal Offroad & Diesel. 6113 Causeway Blvd Tampa, FL 33619 Get Directions (813) 622-6570 Email the Shop

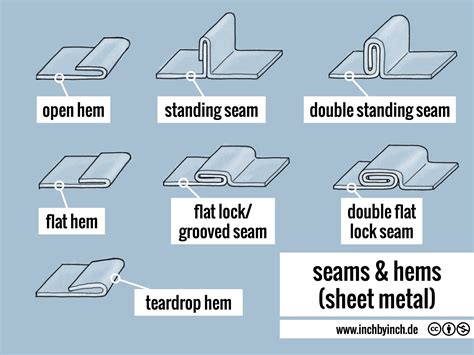

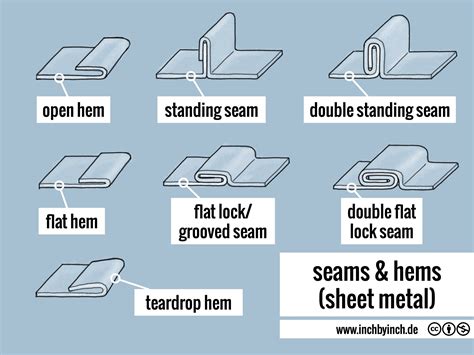

0 · types of sheet metal seams

1 · sheet metal joints and seams

2 · sheet metal hem design guide

3 · sheet metal hand hemming tool

4 · seaming process in sheet metal

5 · hemming tool for sheet metal

6 · hemming process in sheet metal

7 · difference between hemming and seaming

Connectors are among the main distinguishing features of the modules. They are used in order to prevent misconnection. The solar photovoltaic industry uses several types of connectors or standard non-connector junction boxes. Here is an article on the main types of connectors.

types of sheet metal seams

The four most common types of sheet metal hems used by Approved Sheet Metal are closed hem, teardrop hem, open hem, and rolled . Sheet metal hemming involves folding the edge of a metal sheet back onto itself. The purpose is to smoothen sharp edges and increase strength. It's widely used in sectors .

The conditions and rules for press brake forming hems on sheet metal.

18ga galvanized sheet metal naples florida

Hemming in the manufacturing of sheet metal involves folding a piece of metal over into itself, much like the standard sewing process that keeps the cloth from fraying at the ends. Sheet . In sheet metal fabrication, the hemming process involves bending the same part’s sharp edges to form a reinforcement channel. This process is widely used across the automotive and electronics industries. It cuts thin sheet .Sheet metal hem is a fabrication process where the edge of sheet metal is folded over onto itself, creating a smooth, rounded finish that enhances the final product’s safety and aesthetic appeal. This post will take you through the . Sheet metal hemming is a type of sheet metal fabrication in which the thin sheet is bent and folded onto itself. The bent can have a closed shape, completely touching the metal surface, or be open with a slight cavity in .

This is putting a simple hem on a curved piece of zinc with a 7ft radius.Wuko6200:https://www.stortz.com/product/wuko-uber-bender-6200/ Wuko 4010:https://www. How To: Tip an edge on sheet metal with Hand tools - Fabrication That Doesn't Suck#HomeMadeTools #Fabrication #SheetMetalWorkWanna send me stuff? Email myka.

To model hems in sheet metal, I'm: - making two successive flanges - extruding away the intervening flat section - joining the bodies to make a 180 degree (e.g.) bend. Seems to work but wondering if there's a better . What is the typical length of a hem in sheet metal? Typically, hemming is performed on sheet metal in thicknesses, 0.040″ to 0.125″. In open hems, the return length of the hem is typically 4 times the thickness of the hem. Whereas, in closed hems, it’s 6 times the metal thickness. So, its maximum length is 0.75 inches.

Adding a hem means to attach a sheet which is folded by 180 degrees. To add a hem you click an edge to specify where you want to add it. The edge you pick (1) specifies also the hem's folding direction. You also need to specify the length of the hem and the hem distance. Rapid Sheet Metal has created a series of video sheet metal design technical tips for design engineers. The idea was conceived by the engineers at Rapid She. Demonstration of Hemming with a Bending BrakesTo get started, click the Hem feature from the list of sheet metal tools in the toolbar. Then select an edge or side face of a sheet metal part, and define the details of your hem. There are three hem types to choose from:

Hi @ROHANBHATT2110 While there is no Hem command in Fusion, you can still create a hem in a more manual way. Once you have your sheet metal flanges created, place a sketch on the face of one of the flanges and then sketch the profile you want for your hem. Sheet Metal Hemming vs. Seaming: While hemming folds the edge, seaming joins two metal sheets together. While both processes involve joining two pieces of metal, hemming focuses on creating a finished edge, whereas seaming typically involves overlapping edges without the need for a clean finish.

The CAD hem’s angle can be adjusted past 180 degrees to create a closed teardrop or underbent to create an open hook. To bead an edge, simply select that hem type in the hem feature’s setup. The model with hemmed edges is shown in Figure 1b. As a design element, the hem creates the appearance of greater thickness without adding much weight.

I discovered this trick to hemming around a corner in Solidworks 2019. Maybe they will add this feature one day, but for now this works well. Subscribe for m.

Sheet Metal Hemming vs Seaming. As we mentioned above, sheet metal hemming is a process of folding the edge of a single metal sheet back onto itself to create a clean, finished edge. This is typically done by bending the metal over a die or roller, resulting in a 180-degree fold or a tighter, more acute angle. Hemming provides a smooth, rounded .Brakes and saw tables from Tapco Tools offer the utmost precision to create a high-quality, finished look for custom exterior trim. As the industry leader in. Column 1: S = Sheet metal thickness; Column 2: A = flattening height; Column 3: Necessary force per metre to flatten sheet metal with 450N/mm 2 tensile strength (mild steel), 1 T = 9.8 KN; Column 4: flatten sheet metal with . Using a Wuko 2050/4010 combo to make a 180° hem on a curved piece of copper. These tools allow the user to freehand bend on inside and outside curves to crea.

A hem feature creates a rigid edge for a sheet metal part. Modeling hems can be as easy as selecting the edges where you want to place them.In this video you. Alternative ways to create a hem in the Fusion sheet metal workspace: Cut and combine flanges Create two flanges of a 90-degree angle separated by a distance. Use the extrude command with the cut operation to divide the two flanges into two separate solids selecting the vertical face. we will learn sheet metal basic features like Base flange, Edge Flange, Hem and Extruded Cut in Solidworks sheet metal.1)Solidworks tutorial for Beginners.ht.

Sheet Metal Bender. Beginner's Guide To Steam Bending Wood. Learn MIG Welding Tips From a Pro. 8 Tips to Make Concrete Demolition Just a Little Easier. . Set the coil close to where you think it needs to be and pull the hemming handle forward, but not all the way into the locking position. Just pull it far enough so the locking anvil holds . In this Tech Tip we will explain about Creation of Hem in sheet metal in Autodesk Inventor. To create a hem in sheet metal using Autodesk software. In Autodesk Inventor, creating a hem in sheet metal involves defining material thickness, sketching the hem profile, and using specialized tools to fold and reinforce edges for enhanced structural integrity.

Hemming (or flattening) is a great way to finish sharp edges and to strengthen parts after bending sheet metal. 443-459-5496 . If you have any questions on hemming sheet metal or would like to know more about our hemming solutions, don't hesitate to .The hem tool adds a hem to your sheet metal part at a selected edge. Here are some additional items to note about the hem tool: The selected edge must be linear. Mitered corners are automatically added to intersecting hems. Contents. Hem .

Bending, Cutting, Notching, And Folding Standing Seam Metal Roofing Panels. Detailed How To Instructions For Standing Seam Panels At The Eave Ends Of The Roo. There are four types and different sizes of hem. They are Closed, Open, Tear drop and Rolled types. 1. Closed Hem. Select the edges and select the “closed” type from the hem property manager. You can adjust the size of the hem too. 2. Open Hem 3. Tear Drop Hem 4. Rolled Hem. This is the way to use SolidWorks Sheetmetal hem feature.

Hemming is an important operation in sheet metal forming. This is done for automotive body panels and automotive parts such as deck-lids, trunk-lids, doors, .

I built some custom doors for a bike shed. I wrapped them in metal for durability, and in this video I show how I bent the trim coil used on those doors. Hem.

18x18 metal junction box

He claims he has a large metal box that was abandoned by a diplomat from England saying its full of money. And he will give it to me for the low price of $3,700. I'm just wondering if anyone else seen these scams before.

how to hem sheet metal|sheet metal hem design guide