small metal fabrication shop layout SMACNA In the Shop focuses on shop operations and provides SMACNA contractors information on shop-specific activities including: fabrication and prefabrication, safety & health, shop layout, technology, and training.

Packaging in the metal fab industry requires collaboration between the supplier, the customer and often a packaging supplier. Understanding the application, durability of the finish and how a part is introduced to an assembly line, can direct a project manager to the appropriate packaging.

0 · sheet metal manufacturing shop layout

1 · sheet metal fabrication shop

2 · metal machining shop floor layout

3 · metal fabrication shop floor plan

4 · metal fabrication processes

5 · fabrication shop layout template

6 · fabrication shop layout design

7 · fabrication shop design

A junction box – also known as an ‘electrical box’, ‘jbox’, ‘or ‘terminal box’ – is a protective box where wires are interconnected. Junction boxes are often built into the plaster of a wall, in the ceiling, or within concrete.

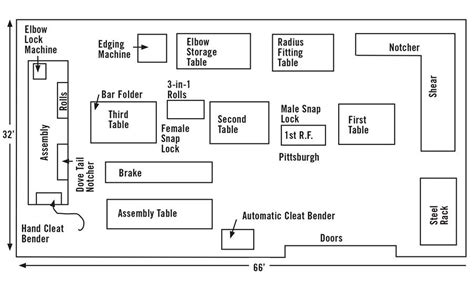

Imagine you’re launching a fabricator today and decide to lay out your small shop like this—but unlike entrepreneurs of previous generations, you also make full use of software from the get-go. Software also helps streamline .A well-organized sheet metal fabrication shop layout is crucial for maximizing efficiency, productivity, and safety. By optimizing your shop's layout, you can reduce wasted time and . Whether you run a small metal fabrication or HVAC shop and you’re looking to expand your business, or you’ve already started expanding and need to optimize workflow, the following principles will help determine the . Metal fabrication is becoming increasingly competitive as shops and factories seek to add value to their existing work — so every little bit of process improvement will help you. Start optimizing your process today.

Metal fabrication in a small shop: The hidden blessing of having no space. How being small helps a shop focus on the big picture. By Tim Heston. December 5, 2016. Article. Shop Management. Without space, excessive work . SMACNA In the Shop focuses on shop operations and provides SMACNA contractors information on shop-specific activities including: fabrication and prefabrication, safety & health, shop layout, technology, and training.

The Principles of Shop Layout. When a sheet metal contractor is setting up a shop, there are 6 basic principles to setting up a better shop: 1.) Work Flow. A good shop layout makes use of a work area arranged so that the .Your metal shop floor layout may be the culprit. At Mac-Tech, we use our expertise to help machine shops create a metal shop floor plan that works efficiently, provides enough space for .A properly laid out workspace will have a certain flow to it. This means the fabrication process should follow a logical progression, from the way you bring raw material into the shop to how you store, cut, clean and prep, drill, bend, .We have been engineering parts and serving customers since 2019 with CNC sheet metal cutting and all finishing techniques, including powder coating and basic surface finishing. Our team of experts is dedicated to precision and .

Hiring the right team is fundamental to the success of your fabrication shop. Metal fabrication requires specialized skills, so look for employees experienced in welding, metalworking, and CAD design.

sheet metal manufacturing shop layout

Alron was founded in 2004 by Alan Notz and Ron Gritzan as a small custom sheet metal fabrication shop focused on getting the job done quickly and for the right price while not sacrificing quality. In 2014, we added a fully equipped .It allows for a more flexible and compact shop layout compared to traditional fabrication machines. . That, coupled with its small footprint, provides remarkable flexibility for laying out a fabrication shop. For example, raw materials are often stored outdoors, so the PythonX STRUCTURAL infeed conveyor can be placed outside the building for . Small Woodshop Layout Ideas. I often receive messages asking to see how I layout my woodshop. I’d love to share pics of my shop with you, but there’s a big issue. My shop is small! It’s around the size of an average bedroom. It measures about 12×13. Which is only about 156 square feet.Best Metal Fabricators in Broomfield, CO - Rod and Forge, Rock 'n' Weld, Atomic Forge & Welding, Geoffrey Newton Metalwork, Perry Tool & Die Company, Sam's Welding Services, Moonblood Custom Fabrication, A&E Technologies, .

Metal fabrication is an umbrella term that refers to many different aspects of metal craftsmanship. Metal bending, cutting, finishing, and welding all fall under the umbrella of metal fabrication. Whether you are a small business owner or a creative homeowner with a project in mind, get the high-quality metal fabrication your project deserves by working with a metal fabrication .

How being small helps a shop focus on the big picture. By Tim Heston; December 5, 2016; Article; . Some metrics in custom metal fabrication tend to cloud reality, even cause confusion. A chart on the side of a laser cutting machine may show high machine uptime or parts-per-hour rates, but overall output still may be suffering. .

This means making ductwork fabrication as quickly and as cheaply as possible; it does not necessarily mean investing a lot of money in new equipment. . with the least amount of handling. To arrive at the best shop layout, sheet metal works contractors must consider numerous factors, including the building available, current machinery and .

sheet metal fabrication shop

metal machining shop floor layout

metal fabrication shop floor plan

Optimizing the fabrication process can help ensure your success. Keep the fabricator involved — In many cases, metal fabricators are not included in the product design process: they don't see the part they're meant to manufacture until the finished designs cross their desk. This is a big problem if, as in most cases design and fabrication are . Planning and scheduling operations at the steel fabrication shop pose distinctive challenges due to one-of-a-kind girder design, multi-project simultaneous execution, and limited limits of the .

Running a sheet metal fabrication shop requires careful planning, efficient operations, and a focus on quality. Here is a list of best practices to consider: Equipment Maintenance: Equipment maintenance is a crucial aspect of sheet metal fabrication, ensuring optimal performance and longevity of the machinery. Regularly maintaining and .

Versatility of The Shop. Design your woodworking shop layout with versatility in mind. Make sure it is flexible enough to accommodate future changes and upgrades. For example, ensure the layout allows for adding new tools or repositioning existing ones without significant changes to the overall design.

We take immense pride in our metal fabrication team's capabilities, honed over years of expertise, to handle projects of all sizes with impeccable precision and attention to detail. From the smallest custom metal fabrication requests to the grandest industrial ventures, our commitment to delivering outstanding results remains steadfast. The backbone of our success lies in Design Components, Inc. has been a leader in the Design, Engineering as well as Distribution of Metal Building Accessories since 1978. By offering outstanding customer service with products that meet the highest . A properly organized metal fabrication shop benefits both the company and its customers in the following ways. Safety. . Follow Poka-Yoke techniques, or error-proofing, by automating processes or incorporating .

Allow me to elaborate on each step mentioned below to incorporate it into your shop design to save space on your small shop layout. Mobile Tools. One way to maximize your small workshop space is by making your woodworking tools .I run a metal fab/design prototyping shop. I have a Brake press, waterjet, mills, lathes, etc. The issue is finding your niche. You need to find a type of work that will keep the machines running. There's a ton of competetion for just "metal fab" but if you can speacialize in something that's more production and not one-offs you'll make good money. Partner with technical schools — Technical schools are great resources for people who have an interest in fabricating, metalworking, and welding — and for businesses that want to find those people.Technical schools frequently offer boot camps where applicants can receive basic job-readiness training and even job offers upon completion.. Metal fabricating .

Dec 27, 2023 - Explore Kirk Imus's board "shop layout" on Pinterest. See more ideas about welding projects, welding table, metal projects.

The following blog post is part three of a multi-part series in which Mestek Machinery discusses the importance of a good shop layout and the ways in which our customers can improve their shops’ productivity by creating an efficient environment for production. You can read the first two parts here.. Why Does Shop Layout Matter? Although it may seem obvious in .Custom Manufactured Metal Parts: From prototype development to short production runs and large-scale sheet metal fabrication, Short Run Pro offers end-to-end custom metal manufacturing services. Our experienced team can assist you in designing and fabricating steel parts to your exact specifications, ensuring precise and reliable results.

micro machining cnc machining manufacturers

Best Metal Fabricators in Mesa, AZ - Lewis Hitches, AZ Metals, JM Custom Iron Work, Doctor Welded, Metal Upon Metals, Fritz Custom Welding, Full Spectrum Artworks, Cliff's Welding, Sacred Steel, Industrial Specialty Powder Coating . “Brian was amazing . I had a small metal fabrication issue, . Top 10 Metal Shop in Mesa, AZ. Top 10 .

Improve Your Metal Fabrication Design Software Process. A particular type of metal fabrication software, called metal fabrication design software, can be used during the planning stages. These options can create 2D drawings and diagrams, handle computer-aided designs (CAD), and provide an electronic method for making and modifying parts.Explore our collection of modern shop plans for both hobbyists and commercial applications. Choose from 30x40, 30x50 & 40x60 designs. HVAC duct fabrication shop owners pride themselves on having a neat, clean, and efficient shop. . but HVAC sheet metal fabrication shops are competing for business, and that means we need a different level of organization. . One way to do this is to design a 5S checklist and have different workers score the shop monthly, using the list .What Is Metal Fabrication? Our small metal fabrication shop team loves helping customers develop custom solutions to their problems, whether it’s a simple design or something more complex, like reverse-engineering a replacement part for an older piece of equipment. . but our team is also happy to help any client with a custom metal .

microplane 4 sided stainless steel multi purpose box grater

So how it punches depends on the grade or carbon content of the metal. Most of what you buy in the metal store is mild steel and will form and punch just fine. But you can buy higher carbon content if you like. What you want for body panels or patch panels is going to be 18 gauge mild cold rolled steel in most instances.

small metal fabrication shop layout|metal fabrication processes