cnc part programming for threading G-code G76 Program Generator. Get the Gcode CNC program for your thread based on the following parameters: CNC Controller; Raw material; Thread & tool handedness (RH / LH) Infeed method; Number of passes; Finish pass, . Bring Your Ideas to Life with the X-Carve Pro With the X-CARVE Pro CNC Machine you're not just cutting wood, plastic, or foam – you're crafting pieces that transform spaces, tell stories, and bring your ideas to life. LEARN MORE

0 · thread turning gcode programming

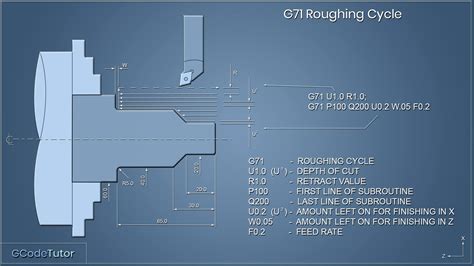

1 · thread cycle programming diagram

2 · thread cycle programming chart

3 · internal thread programming diagram

4 · internal thread programming chart

5 · cnc lathe thread cutting

6 · 3 start thread programming

7 · 3 axis thread programming

I know how to cut brick out for a single gang receptacle, but I would like to know the best way to cut out for a round box for flush mount. Customer wants lights on either side of his garage door and would prefer them be flush mounted.

thread turning gcode programming

G-code G76 is a cnc cycle which is used for thread cutting on cnc machines. G76 Thread Cycle can be used for Taper Threading, Multi-start thread cutting, Internal threading on cnc lathe. This G76 threading example actually cuts external threads on two different diameters.Threading is an integral part of almost every component which is machined, threads .Threading is an integral part of almost every component which is machined, threads .

G-code G76 Program Generator. Get the Gcode CNC program for your thread based on the following parameters: CNC Controller; Raw material; Thread & tool handedness (RH / LH) Infeed method; Number of passes; Finish pass, .

thread cycle programming diagram

thread cycle programming chart

In the 6th video in this series, Marc, aka @GCodeTutor continues the series on manually programming a complete part on a CNC lathe using G-Code.This time, i. There are a few ways to approach thread cutting on a CNC lathe by using G32, G92, or the more common G76. Marc walks us through, line by line on how to write the G .Basic Thread Milling Toolpath. A spiral movement is required to perform a thread milling operation. Helical interpolation is a CNC toolpath along a helical path. This spiral motion combines circular movement (G02 or G03) in the XY plane with .

CNC threading cycles articles, programming examples which shows how to use threading cycle while programming on a cnc machine.

This article delves into the intricacies of CNC threading, exploring its various methods, tool considerations, programming techniques, and best practices for achieving optimal results in your CNC machining center. Get perfect threads every time with CNC Cookbook's guide to chasing threads on a CNC lathe. Learn the tips and tricks from the experts now. List of M-codes. CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)

Learn CNC Programming Basics, G & M Code Tutorials with Example Codes for Beginner to Advance Level CNC Machinist. . Turning Insert Nomenclature Threading Insert Nomenclature CNC Controls . CNC Machine Lock CNC .Multi cut threading macro program example using G76. Custom Macro – Using variables for the Programming : Ideal application for the use of Variable programming (i.e. Custom Macro Programming) on a CNC Lathe : As such the usage is covering very vast application area. You name it and it can be coded using macros.

thesis done on standard aluminum frames fabrication for building

Offline version of INTERCON conversational programming, for use with Windows desktop PC* Add to Cart. Mill, Lathe, and new Plasma Intercon (For use with Acorn Plasma) - For those that do not want to use or learn a CAD/CAM .

Thread milling is a versatile and precise CNC machining method for creating threads in a variety of materials. This article delves into the essential techniques and best practices to ensure successful thread milling operations, offering insights into tool selection, programming, and quality control.• write the part program for the turning. 8.2 EXAMPLES Example 8.1 The component to be machined is shown in Figure 8.1. Prepare a CNC part program to machine it on any turning center using the ISO standard G-codes. You may decide the program zero to be used for the component. Write the program using the initial tool position. The work . Chasing Threads on a CNC Lathe. This is part of our series on CNC Lathe Programming. Repairing threads is a crucial operation for many machinists, either due to the shop handling repair services, or because work needs readjustment for some reason. Manual lathe thread chasing is easy because the machinist has total control over the operation .G02 G03 Circular interpolation CNC mill example program. G02 G03 Example CNC Mill CNC Part Program G0 X30 Y-30 (P1) G1 Y22.67 (P2) G3 X24.07 Y26.18 R4 (P3) G2 X-18.27.

Let’s dive into the nitty-gritty of G32 programming and manual threading, using a practical example to illustrate the process. Understanding G32 Programming and Manual Threading. Imagine you’re tasked with threading a 3.0-12 TPI external thread. Here’s how you’d approach this manually, particularly when G76 isn’t an option.Turning parts are very popular and 2-axis CNC turning programming can be easy for CNC operators and programmers, as the basic operations for completing a part, such as roughing, finishing, drilling, tapping, and threading are less than in CNC milling programming. For this simple part, we present the recommended G-code for Program start/bar .

Cnc programming example of G92 Taper Threading Cycle. ≡ MENU. Home Fanuc Learn Examples Sinumerik Haas Reference Alarms Programming About. Fanuc Fanuc . Threading is part of almost every component that we machine on a cnc machine. There are multiple G-Codes for threading G32, G33, G76, G92. You can cut tapered threads with. CNC programming for beginners can be simplified into six key steps: familiarize yourself with the machine and its capabilities, create or obtain a detailed 3D model of the part, generate the toolpath using CAM software, write the G-code program, set up the CNC machine with the appropriate tools and workpiece, and run the program while monitoring for any issues.CNC Program of External Metric Thread Cutting with G76. External Thread Cutting with G76 Threading Cycle on Fanuc 21i 18i 16i CNC. . Threading is part of almost every component that we machine on a cnc machine. There are multiple G-Codes for threading G32, G33, G76, G92. You can cut tapered threads with.

For the part with a 17/8″ thread length, the thread would be cut in three segments of 0.700″ each. This totals 2.1″, more than what is required, but there will be an overlap of one thread, or 0.050″, for each additional segment after the first. There is .

6. Part programming 1. Part programming consists of a sequence of instructions to be performed on the NC/CNC machine. 2. This are two types 1.Manual part programming. 2.Computer – aided part programming. CNC 3. In order to prepare part programming the programmer decides the order of the machining operations required to produce a component. .

CNC KNOWLEDGE is definitely the CNC Machinist Online Resources. You are warmly welcome to the world of CNC (Computer Numerical Control). CNC KNOWLEDGE provides free and detailed articles about cnc .The Programming Manual "Advanced" is intended for use by technicians with in-depth, comprehensive programming knowledge. By virtue of a special programming language, the SINUMERIK control enables the user to program complex workpiece programs (e.g. for free-form surfaces, channel coordination, .), and makes the programming of complicated

Multi cut threading macro program example using G76 Custom Macro – Using variables for the Programming : Ideal application for the use of Variable programming (i.e. Custom Macro Programming) on a CNC Lathe : As such the usage is covering very vast application area. You name it and it can be coded using macros.A basic cnc programming tutorial which shows how cnc machinists can cut threads on a Siemens Sinumerik 802D sl CNC machine. As Sinumerik 802D sl has threading cycle CYCLE97, although. G20 Turning Cycle – CNC Lathe Fanuc 21 TB #cncprogramming #cncmachine #cnclathe #g76code #cncmachine #cncinformación #gcode #taper #excellentideasineducation #mechanicalengineering #mechanical #cann.Offline version of INTERCON conversational programming, for use with Windows desktop PC* Add to Cart. Mill, Lathe, and new Plasma Intercon (For use with Acorn Plasma) - For those that do not want to use or learn a CAD/CAM system to make CNC parts. - Program parts in the comfort of your office. - Program while the machine is running a job.

To effectively program CNC turning machines, one must have a solid understanding of G-code and M-code. In this section, we will delve into the specifics of these two codes, exploring their functions and syntax. We will provide examples and explanations of commonly used codes in CNC turning programming. Section 3: Setting Up the CNC Turning Machine\Part Programming. Part Programming is the process of entering data, often from a blueprint, into program data blocks to create a part. Data blocks appear in numerical order as they are created. To create a Conversational Part Program: Press the Input console key to display the Input screen.

This document provides an introduction and overview of CNC turning. It describes what CNC turning is, the basic components of a CNC turning machine, important checklists and safety procedures, basic CNC principles including coordinate systems and programming codes, and includes examples of CNC part programs for turning operations and thread cutting cycles.G92 threading cycle is used for threading on a cnc lathe machine. The added benefit of G92 thread cycle is that G92 G-code gives cnc machinist full control over the. Fanuc G76 Thread Cycle for Dummies

The advantage of this is that Arguments can be passed to a program that is called as a Macro Program, whereas a program called as a Subprogram, Arguments can't be passed. Using the ability to pass an Argument to Macro Program, you could pass an argument to initialize the parts counter. Two O-ring grooves with these dimensions. The tool im using is a custom 2 flute profile tool highlighted yellow. Currently running 8000rpm 10ipm with 0.002” peripheral steps from center out. The tools keep breaking while in cut at various parts of the groove. Im on the last of 5 tools and 1st of 4 parts. any help is appreciated. The document provides information about operating and programming CNC lathes. It discusses key parts of CNC lathes like the headstock, tailstock, and turret. It also covers topics like workpiece and tool zero positions, axis nomenclature, common CNC lathe tools, basic operations like turning and threading, and measuring instruments.

internal thread programming diagram

As one of the leading industrial metal fabric suppliers, Marco Specialty Steel is proud to offer an extensive selection of premium woven and welded wire mesh products for any application. We supply many different material grades like copper, aluminum, nickel, or stainless steel wire mesh .

cnc part programming for threading|thread cycle programming chart